With more than two million e-motors produced and the high-voltage vehicle electric system with 800-volt technology, which will go into series production this year, technology company ZF is gearing up aggressively to support the emerging requirements of the mobility of the future.

The company is setting the pace in the dynamic electromobility market and is further expanding its role as a technology and innovation.

Stephan von Schuckmann, Member - Board of Management, ZF, responsible for e-mobility within the Group, said, 'The great interest of manufacturers in our products in both the passenger car and commercial vehicle sectors is confirmed by our high order backlog in the high-voltage business. With the next generation of electric drives, we are consistently continuing our strategy of developing sustainable and efficient mobility for the future.'

System Approach

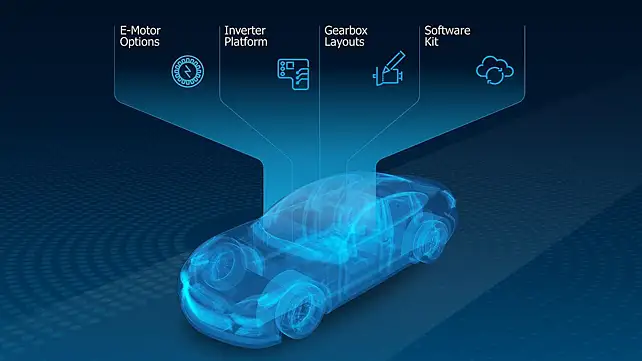

The Germany headquartered company is already developing its comprehensive product range for pure e-drives with a view to the functions desired by customers and end users. To better and faster meet the highly diversified market demand, it is now presenting a new generation of electric drives based on an overall modular concept with an electric motor, inverter, transmission, and software.

Markus Schwabe, Product Line Manager Electrified Powertrain Systems, said, 'We are focusing on three basic systems that meet our customers' main requirements, namely efficiency, performance and cost, even in the standard version. On this basis, we can optimally implement further individual customer requirements in e-vehicles of all segments.'

Innovative Strengths

With the new generation of e-drives, the technology company provides fully integrated electric drive systems. With its high level of interface expertise and unique know-how for driving strategies, the application engineers can meet customer requirements fully in the best possible way. However, the Group will also offer the innovative components individually, on which its own system solution is based. 'Thanks to sophisticated internal interfaces, the new, extremely compact design allows system or component adaptations to be made with little effort. In addition, the design has very high structural rigidity, which enables superior noise behaviour,' explains Dr Otmar Scharrer, Head of Development for Electric Drive Technologies.

The new generation of e-drives will be available on the market as a complete system starting in 2025. It will bring individual components into series production earlier. With 'discrete package technology', power electronics manage the balancing act between a high degree of component uniformity and high adaptability. Individualisation occurs at the chip level: A discretely structured ZF inverter is built with individual power semiconductor switches. This modularity offers better performance scalability than is possible with complex power modules. In addition, ZF's 'discrete package technology' requires fewer types of components than using conventional power modules. 'With our new approach to power electronics, we can serve different market requirements faster and more precisely,' explains Scharrer.

The global company is banking on its range of new technologies, including integrated e-motor, the new cooling concept, coaxial reduction gearbox and high-voltage converters(DC-DC converters). The new high-voltage converter from the ZF power electronics platform, which was developed for passenger car and commercial vehicle applications, has a top value of 99.6 percent in terms of efficiency.

These initiatives help the company set standards through enhanced power density and energy efficiency, offering innovative solutions at both the component and system levels.

With its modular concept, the new e-drives support automotive manufacturers in customising the further electrification of their entire model range. In addition, the new technologies offer higher efficiency, more power, and shorter charging times for end customers.

Also Read:

ZF Surpasses Two Million Production Mark For Electric Motors