Volvo Cars has announced that the company, along with Northvolt, will open a joint research and development (R&D) centre in Gothenburg as part of a SEK 30 billion investment in battery development and manufacturing.

The R&D centre will become operational in 2022.

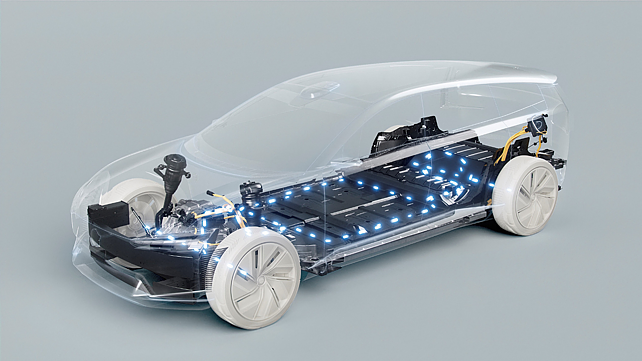

The new R&D centre in Gothenburg will be established by the construction of a new manufacturing plant in Europe. It will produce next-generation state-of-the-art battery cells, specifically developed for use in next-generation pure electric Volvo and Polestar cars. The exact location of the plant is expected to be confirmed in early 2022.

The R&D centre will be in close proximity to Volvo Cars’ own R&D operations and to Northvolt’s existing innovation campus, Northvolt Labs, in Västerås, Sweden, ensuring synergies and efficiencies as it develops battery technologies.

Following the partnership announced by both companies earlier this year, Volvo Cars and Northvolt have now signed a binding agreement this week to create a joint venture for the development and sustainable production of batteries for the next generation of pure electric Volvo cars.

As for their joint battery plant, Volvo Cars and Northvolt are in the final phase of a selection process to find a suitable location in Europe. The plant will have a potential annual capacity of up to 50 gigawatt-hours (GWh), which would supply batteries for approximately half a million cars per year. It will start construction in 2023, with large-scale production in 2026, and is expected to employ up to 3,000 people.

Alongside battery supply agreements, the partnership with Northvolt secures the European battery cell needs that are part of Volvo Cars’ ambitious electrification plans. It aims to sell 50 per cent pure electric cars by the middle of this decade, and by 2030 it aims to sell only fully electric cars.

The partnership with Northvolt is key to Volvo Cars’ ambition to become a leader in the premium electric car segment and sell only pure electric vehicles by 2030. It also represents an important step in strengthening Volvo Cars’ development capabilities.

A press release from the company said the R&D centre, will position Volvo Cars as one of the few automotive brands to make battery cell development and production part of its end-to-end engineering capabilities.

Hakan Samuelsson, Chief Executive, Volvo Cars, said, “Our partnership with Northvolt secures the supply of high-quality, sustainably produced batteries for the next generation of pure electric Volvos. It will strengthen our core competencies and our position in the transformation to a fully electric car company.”

The partnership will develop tailor-made batteries that give Volvo drivers what they want, such as range and quick charging times. In addition, Volvo Cars is working with Northvolt to create a true end-to-end system for batteries, whereby it develops and builds the hail itself. This deep vertical integration is important since the battery represents the largest individual cost component in an electric car and a significant part of the carbon footprint.

Peter Carlsson, Chief Executive, Northvolt, said, “Volvo Cars is an excellent partner on the road towards building up a supply of battery cells that are made in Europe with a very low carbon footprint, and that are optimised through vehicle integration to get the best performance out of the next-generation EVs.”