Leading global automotive fluid systems supplier TI Fluid Systems has introduced an innovative approach for coolant fluid management on Electric Vehicles (EVs).

TI Fluid Systems has received their first ITMa global EV platform application release for the model year 2023 introduction with a leading high-volume European OEM.

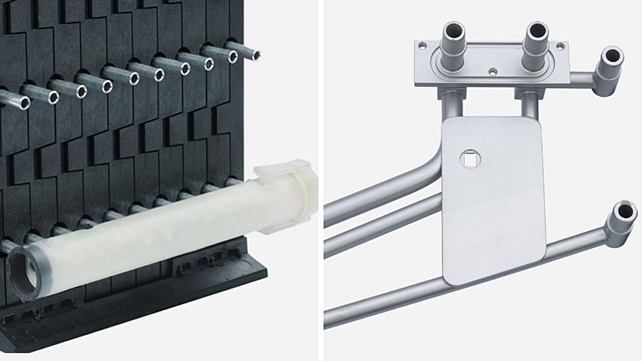

According to the company, the new technology, an Integrated Thermal Manifold assembly (ITMa), provides a one-piece, light-weight, blow-moulded plastic manifold to optimise complex line design. It replaces multiple line bundle assemblies of thermal loops for heating and cooling on next-generation EVs.

The current EVs use multiple complex rubber, aluminium or multi-layer plastic lines packaged tightly together underhood or chassis mounted. TI Fluid Systems has developed the ability to evolve their Fuel Tank and Delivery Systems (FTDS) division fuel tank blow moulding technology to produce a single piece integrated thermal 'manifold' (ITMa) approach. According to the company that has manufacturing facilities in 107 locations across 28 countries serving all major global OEMs, this single piece blow moulded plastic manifold has significant OEM EV value. It will have improved flow performance for efficiency gains, lower part count for sub and final vehicle assembly, with lower weight and reduced investment tooling costs.

In addition to the ITMa coolant 'fluid carrying' design, the company's FTDS division has showcased further integration potential for 'fluid storage' (coolant reservoir expansion tank), 'fluid temp control' (heat exchangers/sensors) and 'fluid delivery' (pumps), for a very compact module solution.

Much like a fuel delivery module, the integrated thermal modular assemblies are specific to OEMs or application and can be engineered for various system types of multiple thermal loops, the company said.

Hans Dieltjens, COO, said the company is demonstrating the ability to pivot its fluid competencies, capabilities and assets to provide a family of new break-through EV products with various levels of integration.