Challenging the status quo of the traditional way of manufacturing, this Chandigarh-based EV start-up wants to manufacture electric commercial vehicles in “micro-factories” in India.

This, the start-up believes, will make automotive manufacturing a cost-effective and easier-to-achieve unit economic model.

Building an automotive plant spread over hundreds of acres with big robots, paint shops, press shops and warehouses to store components gulps down millions of dollars in investment, and takes a decade to achieve profitability.

EVage is looking at breaking the traditional model with its idea of micro-factories.

The company, which plans to launch its first-ever electric commercial vehicle of payload up to one tonne in the next quarter, will be building small micro-factories across India to meet demand locally and economically.

These factories can be built in a time frame of six months to one year, much faster than a traditional manufacturing facility that takes a minimum of two years and requires large land space and investment.

What is an Exoskeleton Structure?

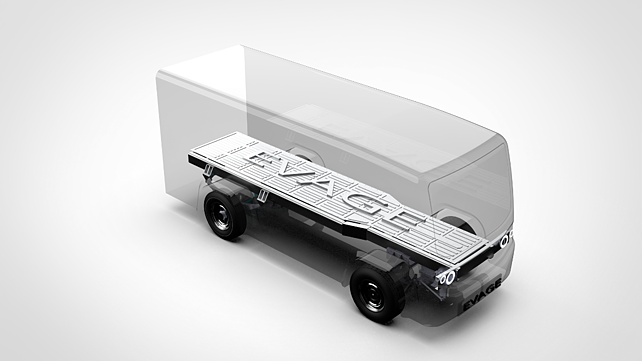

In an exclusive interaction with Mobility Outlook, Inderveer Singh, Co-Founder & CEO, EVage Ventures, also known as Ivee, said the company has a unique patented ‘Exoskeleton Structure’,which will serve as a common architecture for SUVs, vans, delivery vehicles and trucks. The same platform can be used to build six-seven types of vehicles, Singh said.

“This will enable us to manufacture electric vehicles in a low-cost model, as it will not require different platforms to manufacture different vehicles,” he said.

He asserted that as a young-age company, EVage wants to build purpose-built vehicles. Singh and his team invested six years in research and development to rethink the way vehicles are developed and manufactured.

EVage currently employs over 30 employees with R&D engineers, aerospace engineers and scientists. The company has over 20 patents in its name.

At present, EVage is readying to launch a one-tonne payload cargo commercial vehicle (a delivery van) for intercity transportation with 200 cubic feet plus of space, largely built on an aluminium lightweight chassis. This vehicle can go up to 200 km on a full charge in start-stop city conditions.

It would be largely used for e-commerce deliveries. The company is already testing six of its vans with Amazon.

Fleet operators can do more deliveries per day with this vehicle, as it creates efficiencies from the delivery aspect, Singh claimed.

What is the need for micro-factories?

There is a need for micro-factories in India to challenge the big boys of manufacturing, said Singh. “The nature of the industry is such that you buy 1,000 acres of land, invest billions of dollars, create a capacity of a million vehicles, and then hope to sell the vehicles in millions so that you can offset this cost of initial capital and recover the cost in a decade,” he argued. This makes it counterproductive, and requires one to be a giant to survive. “We need to be efficient in our capital allocation. Why would somebody give you a billion dollars because you have a product in hand? It’s a high risk industry. There are execution risks, and then you hope that the customer likes those vehicles,” Singh said.

The concept of micro-factories, Singh believes, gives EVage a long-term survival strategy. This new concept of production, where vehicles can be built in small modular factories, can be developed in an area of 10,000 to 15,000 square feet, can produce 5,000 vehicles annually and are easy to break even.

Over the next two years, the start-up plans to manufacture vehicles in its own facilities and has plans to contract manufacture later, taking cues from consumer electronics production. It will deploy 20-30 micro-factories across India based on market demand.

In the first year, the company plans to manufacture a few thousands of vehicles at its facility in Chandigarh and have experience centres to market and sell these vehicles.