Euler Motors walks us through its cutting-edge EV manufacturing and R&D facility in Palwal, Haryana. Spanning across 500,000 square feet, the facility represents a significant step forward for the company. The factory has been established with an investment of INR 100 crore and is to become Euler Motors' national hub, driving the expansion of its flagship 3-wheeler HiLoad EV across the country. As the company looks to increase its market presence from 26 to 40 cities by FY25, this facility will be central to meeting the growing demand.

Advancements In Manufacturing

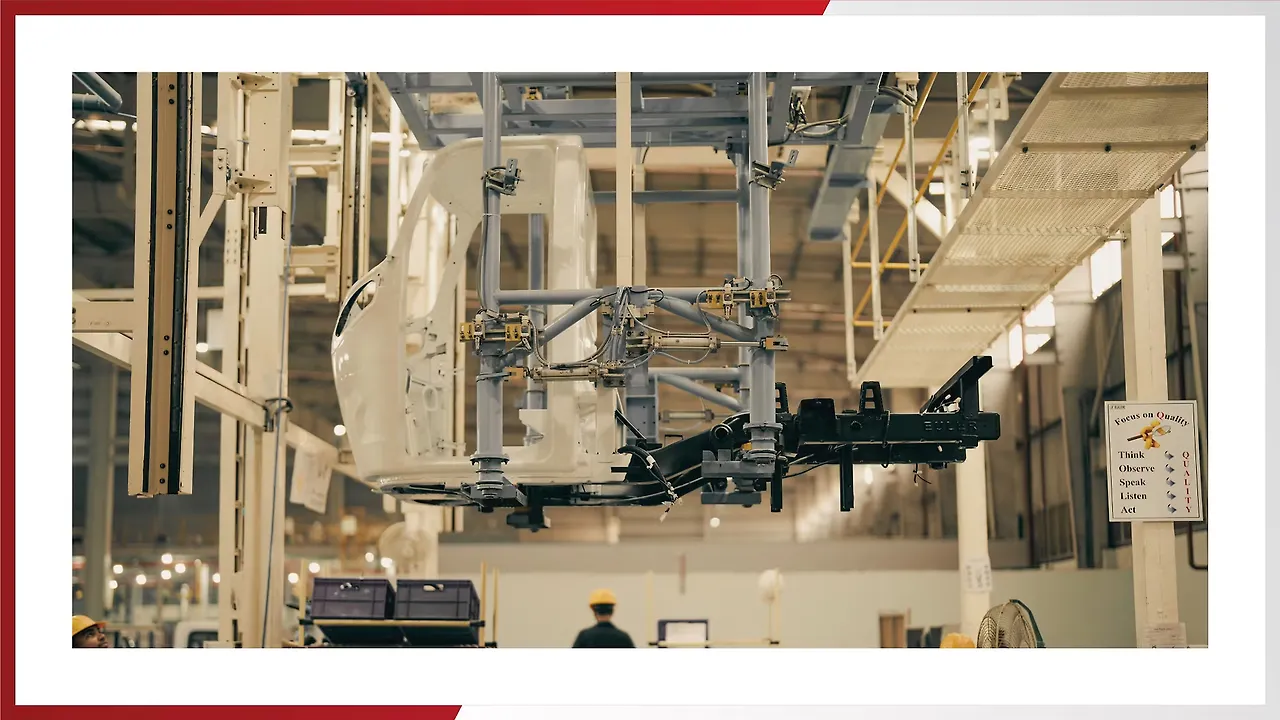

One of the key highlights of the Palwal facility is its incorporation of industry-first automations among cargo EV start-ups. The automated assembly line is connected through a proprietary Manufacturing Execution System (MES), which enhances production efficiency by monitoring every aspect of the vehicle’s lifecycle from assembly to delivery. The facility also boasts several innovative features designed to ensure quality and precision in manufacturing. These include an EMS Hanger system for auto-loading and unloading, a Trailing Arm Fitment Assist for better assembly ergonomics, and a vacuum-based brake oil filling machine to prevent spillage and contamination. Furthermore, a portable Coordinate Measuring Machine (CMM) is used for body accuracy checks, ensuring high standards are maintained throughout the manufacturing process.

Commitment To Sustainability & Quality

Sustainability is a core focus at the Palwal facility, which adheres to Environmental, Social, and Governance (ESG) standards. The plant is equipped with advanced waste management systems, a sewage treatment plant, and a circular groundwater recharge system. These initiatives reflect Euler Motors’ commitment to operational efficiency and environmental responsibility. Additionally, the facility is the only cargo EV start-up with four significant certifications: ISO 9001 (Quality Management System), ISO 14001 (Environmental Management System), ISO 45001 (Occupational Health and Safety), and IATF 16949 (Quality Management System for Automotive). These certifications underscore the company’s dedication to meeting global standards in manufacturing and quality control.

Empowering The Workforce

The Palwal facility is not only a hub of technological innovation but also a centre for empowering the workforce. Currently employing over 500 people, including 20% women, the facility houses a dedicated learning and development centre called ‘Kamar-Taj’. This centre is focused on bridging the skill gap in EV manufacturing, equipping employees with the necessary expertise to excel in this rapidly evolving industry. Key leadership roles, particularly in safety and training, are held by women, reflecting the company’s commitment to promoting gender diversity and empowerment in the workplace.

The strategic importance of the Palwal location is because of the strong supplier network in the region. As the company targets a 15% growth in FY25, this facility will play a crucial role in scaling up production to meet increased demand while maintaining the flexibility to adapt to changes in the market. The facility's advanced technology and focus on quality control position Euler Motors as a leading player in India’s commercial EV sector.

Also Read

Euler Motors Raises INR 200 Crore In Series C Funding, Onboards New Investor