At the on-going Auto Shanghai 2021, leading global supplier to the automotive and industrial sectors, Schaeffler is showcasing innovative component and system solutions, especially for the Chinese market.

Intelligent and sustainable electrification of the drivetrain has proven to reduce CO2 emissions, and Schaeffler has demonstrated numerous series nominations across all levels of electrification at the Shanghai show. Schaeffler is operating successfully in the field of e-mobility, and has solutions for all types of electrification.

Klaus Rosenfeld, Chief Executive Officer, Schaeffler AG said, “As a leader in mobility, we pioneer motion to advance how the world moves. We are the preferred partner for our customers in China and around the world. As an automotive and industrial supplier, this applies to all areas of mobility and every type of motion.”

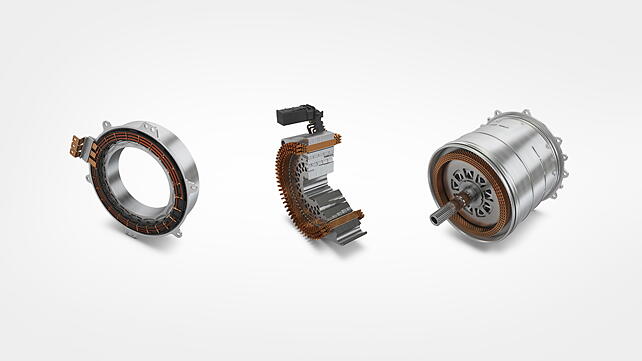

A recent release issued by the company said it would start series production of electric motors for hybrid modules, hybrid transmissions and all-electric axis drives in an application range from 20 to over 300 kW this year. These electric motors are based on a modular and highly integrated technology platform, the company said.

For the first time in the Chinese market, the company will showcase a rolling chassis, a local emissions-free drive solution for large cities.

Schaeffler has put drive and chassis components together into space-saving compact assemblies, called the “Schaeffler Intelligent Corner Modules.” These modules include the wheel-hub motor, the wheel suspension, along with the vehicle suspension system and the actuator of the electromechanical steering. The steering of the wheel module is designed as an electromechanical steer-by-wire system. The shape chosen for the wheel suspension allows for a wheel angle of up to 90 degrees, Schaeffler said.

Tie-Up With Refire

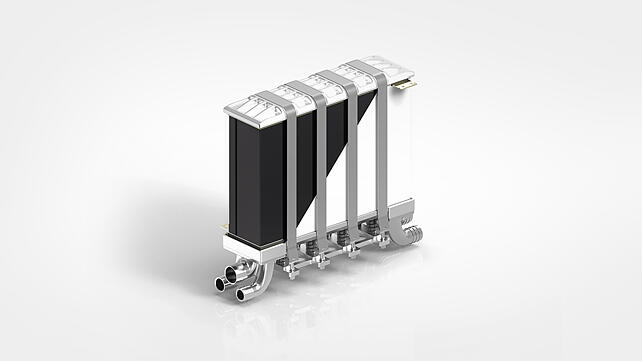

In another key development, Schaeffler has signed a strategic cooperation agreement with Refire, China’s leading supplier of hydrogen fuel cell technology, to develop and manufacture key components for hydrogen fuel cells. As per the agreement, the two companies will cooperate in the key technology areas of hydrogen fuel cells, such as bipolar plates and thermal management systems. The two parties will jointly promote industrialisation of hydrogen fuel cells.

Metallic bipolar plates for fuel cell stacks are manufactured through precise forming and coating in the thin-layer range. Arranged into stacks, they are the core of the fuel cell system and there they play a key role in the generation of hydrogen and its reconversion into electrical energy, said the release.

Electric motors, metallic bipolar plates for fuel cell stacks and rolling chassis are evidence of the company’s successful transformation towards new areas of business, claimed Schaeffler.