Automotive and industrial supplier Schaeffler has announced a new production facility at Szombathely in western Hungary.

According to the company, the facility is its first production plant fully dedicated to electro-mobility and gives the group a new centre of excellence for producing components and systems for electrified powertrains. The facility’s operational footprint has been gold-certified by the German Sustainable Building Council (DGNB) and represents a significant step towards achieving Schaeffler’s goal of making its production activities worldwide carbon-neutral by 2030.

Klaus Rosenfeld, CEO, Schaeffler AG, said, “The goal is sustainable mobility, and we are determined to make real progress in that direction as a key technology partner for our customers by leveraging our global network of production facilities. The new plant also highlights our ambitions to continue our strong growth in e-mobility.”

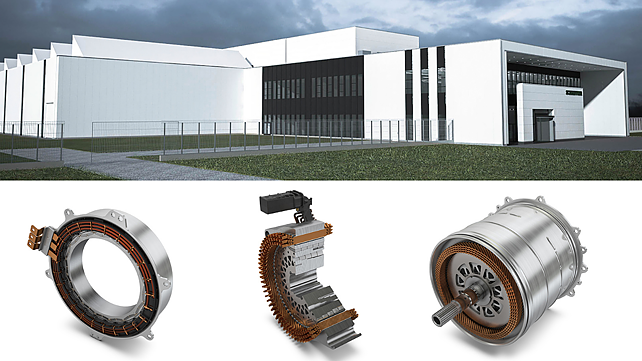

Szombathely-II provides around 15,000 square meters of space to produce innovative powertrain components and solutions, such as electric motors and hybrid drives. Designed as a “factory for tomorrow,” it features a high degree of automation, modular production buildings, and end-to-end digitalisation. Automated production lines and extensive use of industrial robots guarantee the clean, dust-free environment required by sensitive production processes used for assemblies such as stators and rotors and the integration of magnets for synchronous and asynchronous motors.

The company said it will increase the facility’s round-the-clock output capacity to 800,000 products a year by 2023. It has further plans to expand its annual output of finished products for premium partners in the auto industry to 1.8 million between 2026 2029. Dr Jochen Schröder, President, E-Mobility division, Schaeffler AG, said, “The Schaeffler Group expects to be generating new orders of between €2-3 billion annually from its e-mobility business from 2022. Szombathely will make a major contribution towards this growth as a centre of excellence operating in close alignment with our main electro-mobility plant in Bühl, Germany.”