Leading speciality chemicals company Lanxess has announced that it is offering several Polybutylene-terephthalate (PBT)-based compounds that successfully reconcile the two properties.

PBT offers not only high hydrolysis stability in hot and humid conditions but also good laser transparency for laser transmission welding are a speciality. This is because these two material properties are usually mutually exclusive.

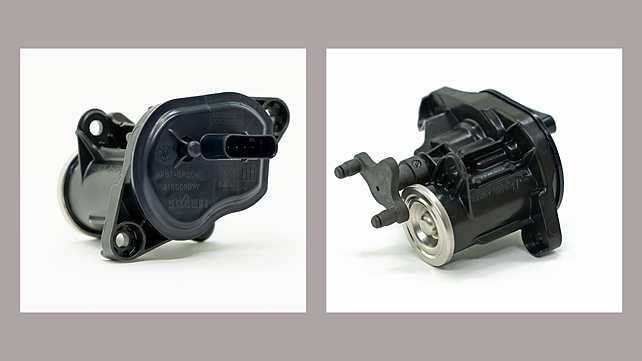

For example, Pocan B3233HRLT (hydrolysis-resistant, laser transparency) is already used in a range of large-series applications and can be employed to manufacture, for example, housings for mechatronic actuators for swirl control.

According to the company, an automotive manufacturer based in the south of Germany equips several of its diesel engine series with these actuators, developed and manufactured by Sogefi Air & Cooling SAS in Orbey, France. The company is part of Sogefi S.p.A., an Italian corporate group that is among the world’s leading providers of filter systems, flexible chassis components and air intake and engine cooling systems for vehicles.

Cost-effective Production

Jean-Marie Olivé, Application Development Expert - High-Performance Materials Business Unit, Lanxess, said, “Our PBT compound has been chosen because it withstands the high temperatures under the hood in a car, even in very humid conditions. Our material is also characterised by its low warpage and high dimensional stability, properties that make it ideal for the complex geometries of these compact housings. And even when the material is dyed black, it still offers a high level of transparency in the wavelength range of lasers usually employed for laser transmission welding of plastics. This ensures stable and efficient welding of the housing components.”

The improved resistance of Pocan B3233HRLT to hot and humid environments is demonstrated in the SAE/USCAR-2 Rev. A finished part is exposed to strong temperature changes at relative humidities of up to 100% over numerous cycles. “In specimen tests conducted in similar conditions, our compound fulfills the requirements of Class 3 and so can withstand temperatures up to 125 °C,” Olive added.

Swirl control actuators are part of the air management systems in combustion engines, and they are responsible for controlling the air supply to the intake module and, at the same time, ensuring sufficient air turbulence. Thus, they help optimise combustion processes and play a key role in ensuring that the engine is highly efficient, ultimately reflected in high fuel economy and correspondingly low consumption figures, the company added.