The boom in electric vehicles is causing a sharp rise in demand for plastics destined for charging infrastructure. Speciality chemical provider Lanxess believes that this area offers opportunities to use its Durethan polyamides and Pocan polyesters.

The possibilities gained by these thermoplastic compounds are demonstrated in a new design concept from Lanxess for charging inlets. These are installed in battery electric vehicles and accommodate the charging coupler of the external charging station.

The design is the outcome of collaborative discussions with manufacturers of charging systems and incorporates the company's experience in numerous charging infrastructure development projects. It implies that the unit will have the ability to be as flexible as possible when it comes to charging inlet sealing. O-rings, sealing cords or family seals are used, like deploying lip seals manufactured in a two-component injection moulding process.

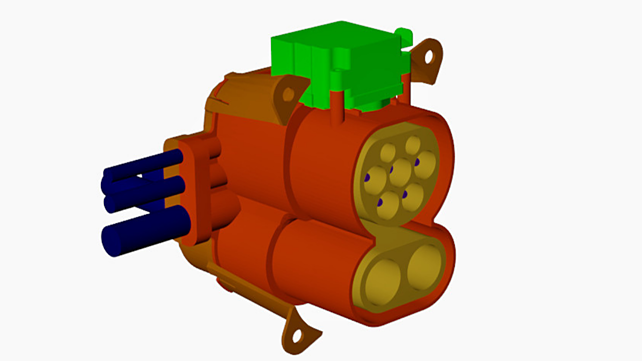

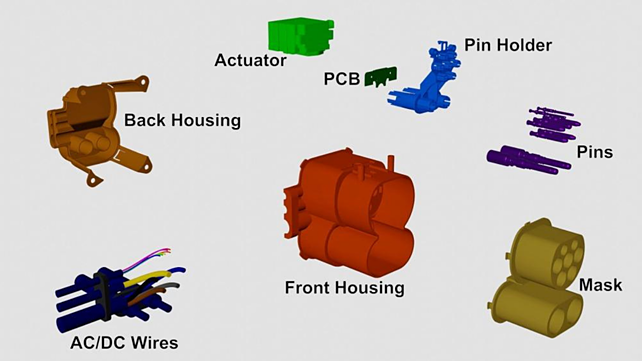

The key elements of this charging inlet design are the front and rear housings, a socket for the connector from the charging station and an actuator. The latter locks the connector in place to prevent it from being accidentally or deliberately pulled out during the charging process.

The pin holder is another essential element, and it holds the metallic connector pins in place and a printed circuit board (PCB) with cables for charging with direct or alternating current.

The pin holder position is critical as it positions the cables such that the heat produced during charging is dissipated through them and via the other cables not in use.

Once the cables and contact pins have been placed in the holder and the PCB has been clipped in, all the charging inlet components are put together with the aid of snap fits, the company said.

The cables are fastened in place under minimum strain so that they cannot become detached in the housing.

Plastics for charging inlets are required to comply with the IEC 62196-1 standard and deliver high electrical insulation resistance and high dielectric strength and tracking resistance.

Good fire-retardant properties are also essential since the parts that come into direct contact with live components must pass a glow-wire end product test (GWEPT) in accordance with IEC 60695-2-11 at a glow-wire ignition temperature of 850 °C.

After being stored at 80 °C for seven days, the plastic parts must not exhibit any surface changes – such as cracks – caused by aging. High-grade mechanical properties (e.g. good toughness) are also required to ensure that the charging inlet is not susceptible to bumps or vandalism.

The company considers applying the new design to further assemblies of the charging infrastructure – such as the charging plug. It can deploy the design and materials expertise built up during work on the vehicle charging inlets because the requirements are very similar.