Leading speciality chemicals company Lanxess has announced the expansion of its range of halogen-free, flame-retardant, glass-fibre-reinforced polyamide 6 compounds to include Durethan BKV30FN01 and Durethan BKV30FN04 DUS064.

According to the company, the products are designed for use in thick-walled components with specially optimized requirements regarding fire resistance. Potential applications include power tools and industrial equipment.

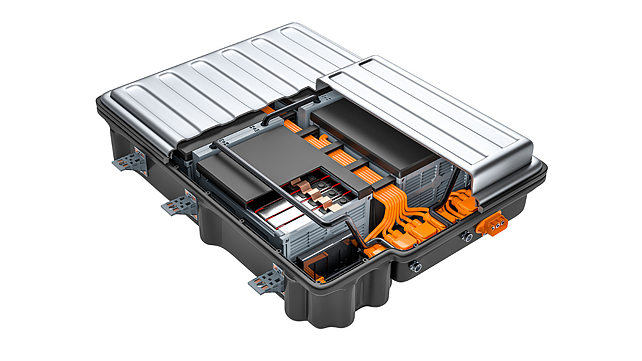

Alexander Radeck, an expert in flame-retardant plastics at Lanxess, said these structural materials also offer outstanding potential in the field of electromobility and its periphery – for components such as thick-walled battery covers or charging plugs and the associated connector holders.

The new products are derived from Durethan BKV30FN04, which is already successfully deployed in the mass production of flame-retardant components. In addition, this compound meets the requirements of the UL 94 flammability test of the US testing institute Underwriters Laboratories, achieving V-0 classification with a test body thickness of 0.4 millimetres, the company said.

The thinner the wall, the more flame retardant is required in the compound to be eligible for V-0 classification. However, many components requiring a high degree of flame resistance are much thicker than 0.4 millimetres, which means that they can be manufactured using compounds to which less flame retardant has been added, but that still offer sufficient fire resistance.

Durethan BKV30FN01 and Durethan BKV30FN04 DUS064 are specially designed for components with wall thicknesses of 0.75 - 1.5 millimetres and more. The compounds have a UL V-0 classification with 0.75 millimetres (Durethan BKV30FN01) and 1.5 millimetres (Durethan BKV30FN04 DUS064).

“Due to the specially optimized flame-retardant package, the material types offer excellent processability during injection molding. They also ensure high-quality surfaces, even with large, planar component geometries,” Radeck said.

The company is planning to expand the Durethan BKV FN range to include easy-flow variants for thick-walled components.