JCBL Marrel Tippers Limited (JML) has announced the expansion of its state-of-the-art manufacturing facility in Oragadam, Chennai. The facility expansion increases JML’s production capacity by 25%, enabling the company to cater to its growing customer base across diverse sectors, including defence, automotive, construction equipment, petroleum transportation, and railways. The enhanced facility spans an additional 60,000 square feet, complementing the existing 1 lakh square feet setup. The company has also outlined plans for a second-phase expansion, adding another 50,000 square feet, with a total of six acres reserved for future projects scheduled in FY 2025-26.

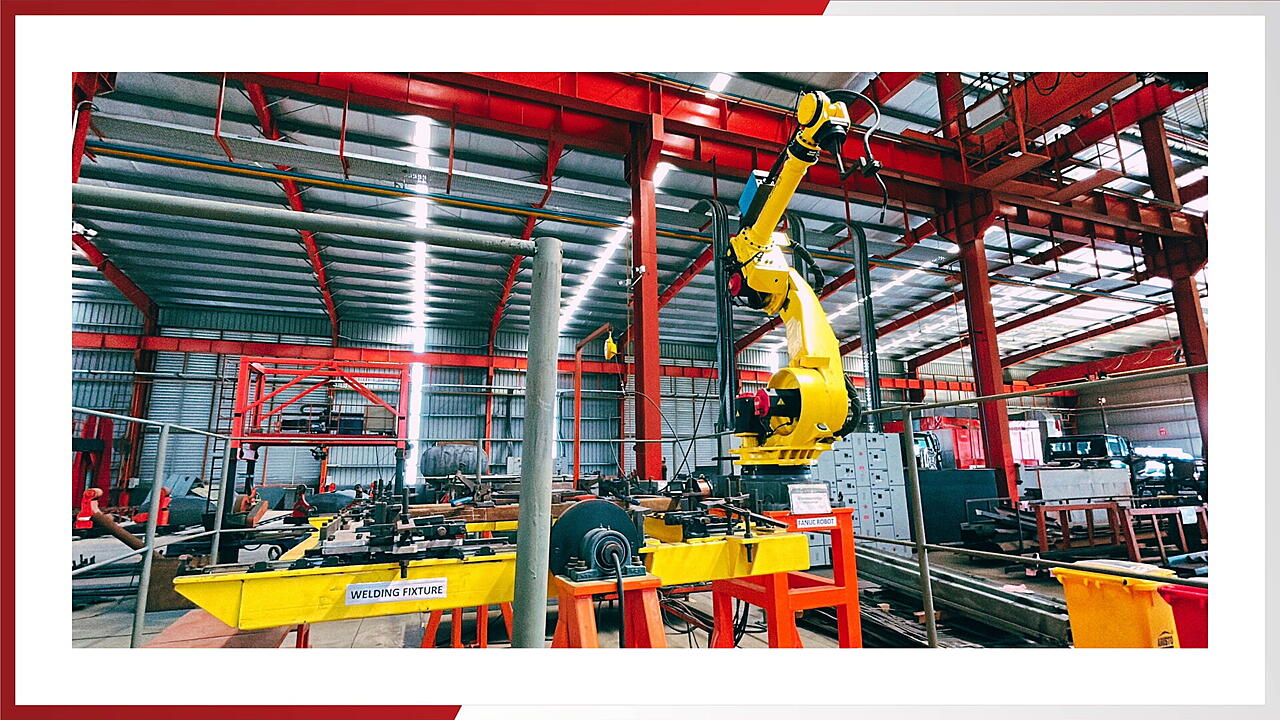

Equipped with advanced technologies, the expanded facility introduces laser cutting systems, robotic welding units, CNC machining tools, airless painting technologies, and heavy-duty EOT cranes. These upgrades ensure superior product quality, increased operational efficiency, and reduced production lead times. The implementation of lean manufacturing principles further ensures precision, waste minimisation, and consistent high-quality output across all production lines.

The facility expansion also brings significant economic benefits, creating 200 new local jobs and providing opportunities for 40 new suppliers in Tamil Nadu. This development underlines JML’s contribution to the regional economy and its role in fostering local industrial growth.

A major highlight of the expansion is JML’s emphasis on sustainability. The facility is powered by a 300KW solar power system, generating 1,350KW of energy daily. Plans are underway to install an additional 1,200KW solar power system, boosting renewable energy generation to 6,750KW per day. Furthermore, JML is incorporating a Water from the Air System to generate 1,500 litres of water daily for its operations.

Environmental stewardship extends to water management, with a Sewage Treatment Plant (STP) producing 6KL of recycled water daily to sustain a green belt covering 30% of the plant area. This initiative supports self-sufficiency in water consumption while maintaining the facility’s eco-friendly infrastructure.