Honda Motor Co Ltd has unveiled a demonstration production line for all-solid-state batteries at its research facility in Sakura City, Tochigi Prefecture, Japan. This state-of-the-art facility is a critical step in Honda’s efforts to mass-produce next-generation batteries, addressing key challenges in electric vehicle (EV) adoption, including range, cost, and charging time. The production line covering 27,400 square metres is set to begin operations in January 2025.

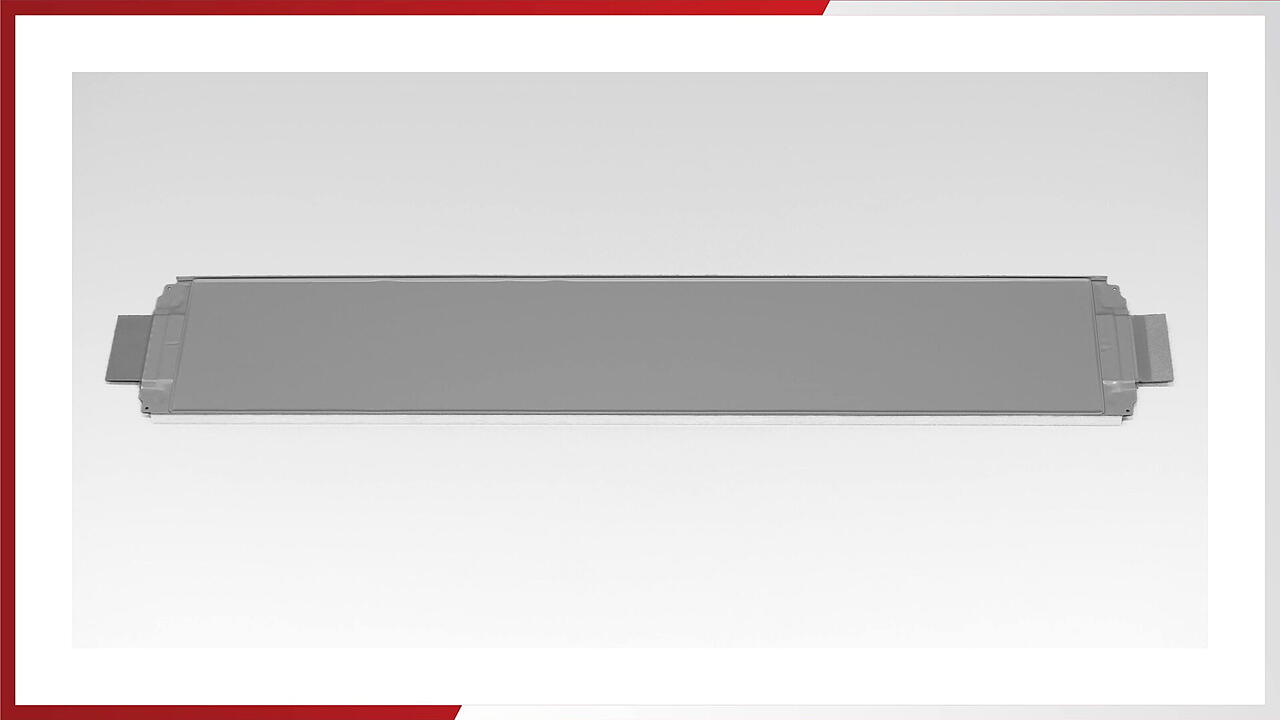

Designed to refine the mass production process the facility integrates advanced technologies such as a roll-pressing technique to increase battery density and productivity. This technique enhances interfacial contact between the electrolyte and electrodes, optimising performance while reducing production time per cell. Honda is also implementing measures to lower indirect costs, including innovative production controls that minimise power consumption.

Honda aims to expand the application of its all-solid-state batteries across its product range from cars to motorcycles and aircraft. By leveraging economies of scale and efficient production methods, the company seeks to reduce battery costs while delivering higher energy density and durability. These advancements are expected to position all-solid-state batteries as a game-changing solution for EVs, overcoming barriers to widespread adoption.

Keiji Otsu, President of Honda R&D Co Ltd, noted that batteries would play a pivotal role in the electrification era, replacing engines as the driving force of automotive innovation.

With a target of achieving carbon neutrality by 2050, Honda has committed to making all new vehicle sales battery-electric or fuel cell electric by 2040. The all-solid-state battery facility is partially funded by Japan’s Green Innovation Fund, reflecting its alignment with national priorities in sustainable technology.

Also Read

Nissan, Honda Forge Strategic Partnership For NextGen Vehicle Technologies