Leading drive systems manufacturer GKN Automotive has announced the launch of its next-generation inverter, offering OEMs an advanced 800V electric vehicle technology.

This latest innovative product from GKN Automotive results from an ongoing mission to push the boundaries of development and drive a cleaner, more sustainable world. GKN Automotive’s Formula E partnership supports this approach with Jaguar TCS Racing, which demonstrates how performance on track can inform the engineering of systems on the road through accelerated development and testing in the extreme, demanding, demanding scenarios.

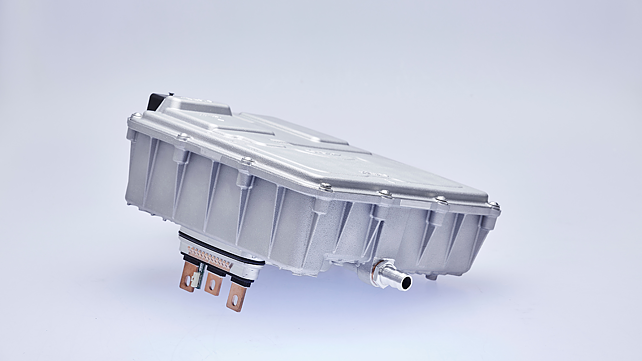

According to the company, the upgraded product features a range of efficiency and lightweighting improvements to deliver market-leading performance and enhanced sustainability. The next-gen inverter, one of three modular elements of GKN Automotive’s leading eDrive platform, offers a 20% power output increase over the previous version. In addition, power density is up by 50%, power-to-weight ratio rises by 60% and copper content is reduced by 63%.

In addition, a key development is the integration of 800V technology, enabling faster charging times, increased battery size, and improved performance for future electric vehicles. By 2025, GKN Automotive forecasts the majority of electric vehicles on the market will utilise the technology. The next-gen inverter is also compatible with existing 400V systems, offering OEMs complete flexibility on existing vehicles.

Christoph Gillen, Director of Systems Engineering, GKN Automotive, said, “The performance we have been able to deliver with the new inverter is an important next step in our mission to drive a cleaner, more sustainable world, as we’ve been able to vastly increase performance and improve efficiency. We believe that the future of EV technology is 800V architectures, so it was crucial that this product supported an 800V range and I’m proud of what we’ve achieved.”