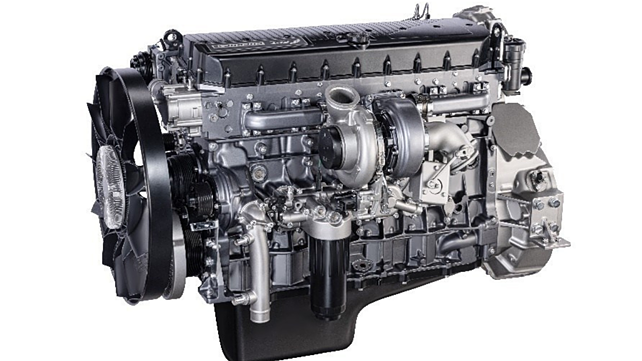

To support the National VI emission standards coming in to force from July 1, 2021, for heavy-duty diesel vehicles in China, Fiat Power Technology has launched three series of power solutions for Cursor9, Cursor11 and Cursor13 engines.

The Cursor National VI engine series, with its patented HI-eSCR after-treatment system, can fully meet China’s stringent emission regulations. The technology can achieve extremely high nitrogen oxide conversion efficiency (>95%), and does not require an exhaust gas recirculation (EGR) system, which can effectively reduce nitrogen oxide emissions and fuel consumption while improving engine performance and reliability Sex. The HI-eSCR system has many advantages. Compared with the system using EGR, the HI-eSCR system can reduce fuel consumption by up to 3%. Besides, the maintenance interval of the DPF is longer, the downtime is shorter, and the oil change interval is longer. The oil change range of the Cursor series engine can reach 150,000 kilometres.

Since there is no need for an exhaust gas recirculation system and no after injection, the structural complexity of the engine is reduced, eventually enhancing the reliability of the engine is better. More importantly, this compact system is easy to arrange and install, and it is easy to switch and upgrade from other systems. In the past 25 years, Fiat Power Technology’s SCR technology has been developed to the sixth generation of HI-eSCR, with eight patents, over 14 years of road application experience, and over 200,000 vehicles equipped with HI-eSCR technology and over 150 in the European market. The market share of 10,000 vehicles of various types equipped with SCR technology. For medium or heavy-duty engines, this is a proven and acclaimed solution.

The Cursor National VI engine series released this time has two key technologies: one is the “Philippine vanadium backing”-vanadium-based after-treatment technology, which eliminates the need for forced parking and regeneration of the engine, and no user operation. The forced parking regeneration button also means that it can effectively increase attendance time, reduce fuel consumption, and provide users with simpler uninterrupted functions that conform to their original habits. Compared with other products, it is necessary to carry out a parking regeneration of 40 to 90 minutes every 8,000 kilometres, which is a significant improvement.

The second core technology is the eVGT transient supercharging technology applied to the Cursor 13 engine. As the best solution for long-distance and heavy trucks with a total vehicle weight of more than 16 tonnes, the Cursor 13 engine adopts a new eVGT technology to achieve the best transient response. In other words, the eVGT transient supercharging technology enables the Cursor13 engine to provide a peak torque of 2,500Nm at speed as low as 950rpm. Therefore, the engine can instantly pry the powerful power when starting and accelerating, which doubles the acceleration response of ordinary superchargers. Besides, the use of eVGT can also improve the Cursor engine’s in-cylinder braking effect by 60% and more effectively reduce brake pads and wear and driver fatigue.