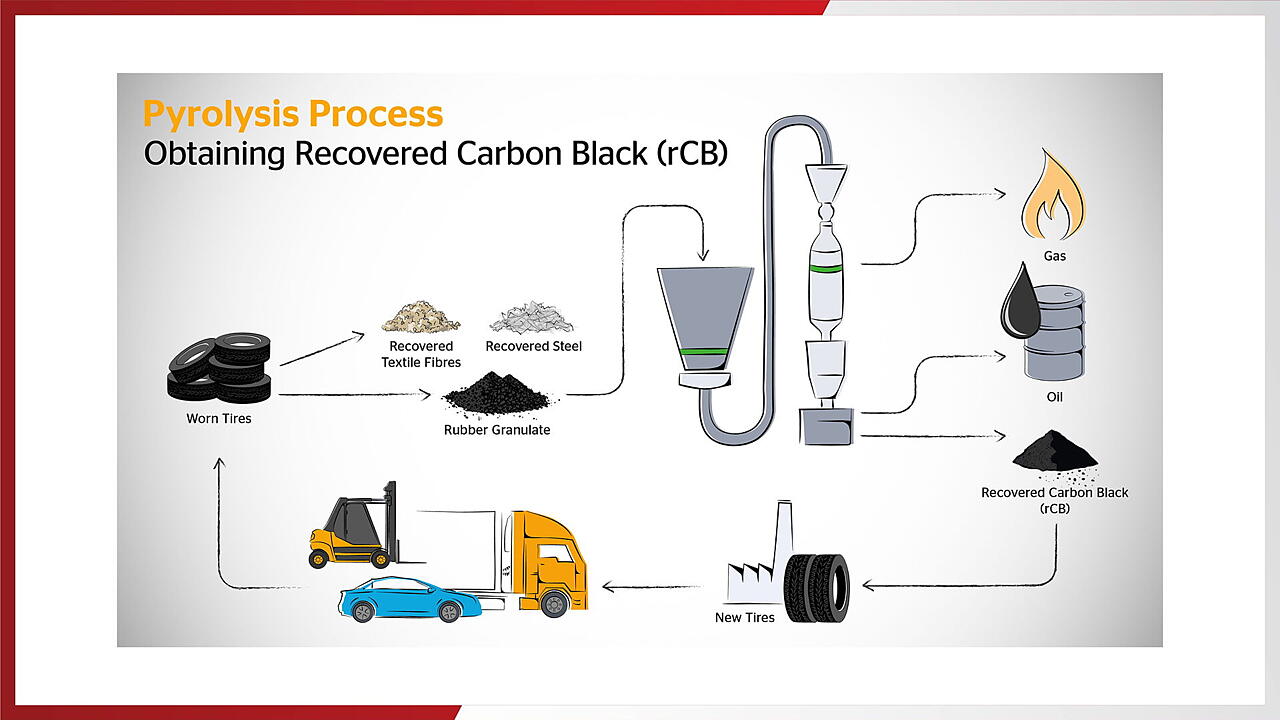

Continental has taken another step towards sustainability by entering a long-term purchase agreement with Pyrum Innovations. The partnership with Pyrum Innovations, a specialist in thermolysis technology for end-of-life tyres, aims to incorporate recovered carbon black into the series production of Continental's passenger car tyres. This move intensifies the collaboration that began in 2022, with both companies dedicated to optimising and expanding the recycling of end-of-life tyres through pyrolysis.

Carbon black, a critical raw material in tyre production, enhances the stability, strength, and durability of tyres. Traditionally sourced from fossil raw materials, carbon black recovered from end-of-life tyres offers a more sustainable alternative, reducing CO2 emissions and the use of non-renewable resources. In Continental’s passenger car tyres, carbon black constitutes between 15 to 20 percent of the tyre's composition, depending on the model. By integrating recycled carbon black, Continental moves closer to its goal of using more than 40 percent renewable and recycled materials in its tyres by 2030.

'Recycled raw materials are becoming increasingly important in our tyre production. To further increase the circularity of our products, we need to think differently. We need to move from an 'end-of-life' to an 'end-of-use' tyre concept,' stated Jorge Almeida, Head of Sustainability at Continental Tyres. He emphasised the importance of developing efficient processes to recycle as many components and materials as possible from tyres that have reached the end of their use phase.

Continental tyres already incorporate various recycled materials, including rubber from mechanically processed end-of-life tyres, recycled steel, and polyester from PET bottles. These initiatives not only prevent waste from ending up in landfills or incinerators but also align with Continental’s sustainability strategy.

The collaboration with Pyrum Innovations marks a crucial step towards achieving a closed-loop recycling management concept, where end-of-life tyres are repurposed as raw materials for new tyres. 'The expansion of our cooperation with Continental is a very important step for us,' adds Pascal Klein, CEO of Pyrum Innovations. He highlighted the success of using sustainable carbon black in the production of new forklift tyres at Continental’s plant in Korbach, Hesse, as a testament to the potential of this partnership.

As part of its broader sustainability goals, Continental aims to utilise 100 percent sustainable materials in its tyres by 2050. Recycled materials will play a significant role in achieving this target, with end-of-life tyres being transformed into valuable resources for new tyre production.

Also Read