Bosch has won a major order to supply electric air compressors with integrated power electronics to cellcentric, the 50:50 joint venture between Daimler Truck and Volvo Group.

The compressors, which govern the fuel-cell system’s oxygen supply, will be part of the cellcentric fuel-cell system that will feature in heavy trucks and stationary applications in the future. Bosch has announced that large-scale production will begin from around the middle of the decade.

cellcentric is responsible for all activities along the entire value chain, and aims to become a leading global manufacturer of fuel-cell systems. With its solutions, the company intends to help make transportation climate neutral and sustainable by 2050.

For long, Bosch has believed in hydrogen’s bright future as an energy carrier, and is making considerable upfront investments in this area. Between 2021 and 2024, the company plans to invest around € 600 million in mobile fuel-cell applications, and a further € 400 million in stationary ones for the generation of electricity and heat.

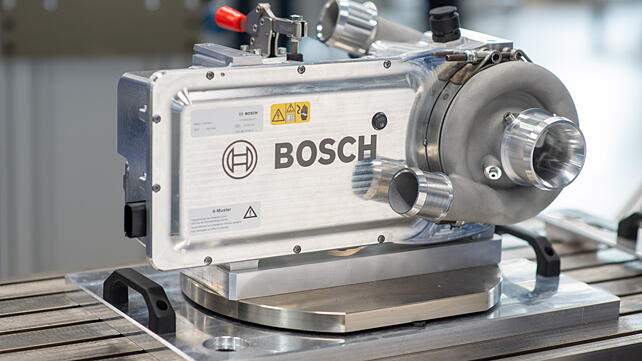

For vehicles, the company has developed a portfolio ranging from individual sensors to core components such as the electric air compressor and the stack to the complete fuel-cell module.

Making CVs carbon neutral with fuel cells

In fuel cells, hydrogen reacts with atmospheric oxygen to produce electrical energy as well as water and heat. Running a fuel-cell powertrain on hydrogen, which is produced using renewable energy, makes the vehicle climate neutral. As the electric air compressor supplies the required amount of filtered air, it is one of the core components of a fuel-cell system.

“Bosch is devoting a huge effort to developing this component. For example, we have 15 cross-divisional teams working to commercialise the electric air compressor,” said Dr Uwe Gackstatter, President of the Bosch Powertrain Solutions division.

The air compressor is being offered in two power classes – 20 and 30 kW. While the 30 kW class is rated for voltages from 450 to 850 V, the 20 kW class is rated for either 250-450 V or 450-850 V. The compressor wheel reaches speeds of more than 100,000 rpm, said the company.

Gackstatter said the combination of a high-speed electric motor with integrated power electronics enables easy system integration at competitive manufacturing costs. In addition, the silicon carbide semiconductors used in Bosch power electronics make this component particularly efficient, claimed Bosch.

Gackstatter further said that with the air compressor, the greatest technical challenge lies in scaling up the production of the high-speed electric motors with their air bearings and power electronics from customised to large-scale manufacturing.