In a strategic partnership, Ansys and Intel Foundry are joining forces to offer advanced multiphysics signoff solutions for Intel's cutting-edge 2.5D chip assembly technology. This innovative approach utilises Intel's EMIB technology, eliminating the need for through-silicon vias (TSVs) and providing flexible die connections.

Ansys' sophisticated simulation engines, integrated into the Ansys RedHawk-SC Electrothermal electronic design automation (EDA) platform, deliver a range of benefits for Intel's 2.5D chip assembly. This collaboration is set to enhance speeds, reduce power consumption, and increase reliability in advanced silicon systems designed for artificial intelligence (AI), high-performance computing, autonomous driving, and graphic processing.

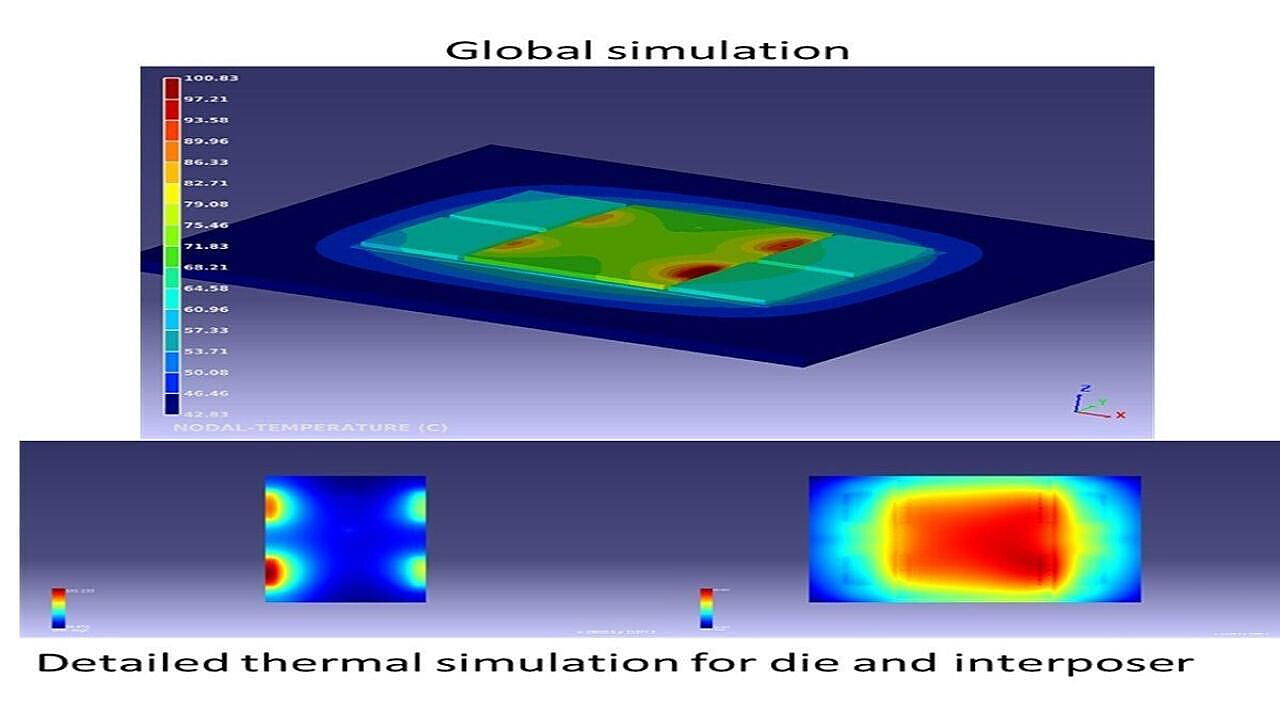

The Ansys RedHawk-SC Electrothermal platform facilitates multiphysics analysis for 2.5D and 3D-ICs with multiple dies. Its capability to conduct thermal analysis with anisotropic thermal conduction aligns seamlessly with Intel's new backside power distribution technology. The platform also addresses challenges related to thermal gradients, mechanical stresses, and warpage, crucial factors influencing product reliability over time. Chip/package co-simulation ensures power integrity verification, providing a comprehensive 3D system-level context for utmost accuracy.

Rahul Goyal, Vice President & General Manager of Product and Design Ecosystem Enablement at Intel, highlighted the unique advantages of Intel's 18A and EMIB technology, emphasising their commitment to collaborating closely with Ansys.

John Lee, Vice President and General Manager of the Electronics, Semiconductor, and Optics Business Unit at Ansys, highlighted the significance of Ansys' multiphysics signoff platform in addressing complex challenges and meeting stringent requirements in thermal, mechanical, performance, and reliability aspects. Lee expressed confidence that this collaboration would provide mutual customers with the flexibility to adopt EMIB technology for superior system architecture and assemble top-tier solutions, ultimately leading to higher performance products and a seamless user experience.

Also Read:

Ansys Collaborates With NI To Drive Innovation In Aerospace & Defense Solutions