The National Institute of Advanced Industrial Science and Technology (AIST) and NGK Insulators Ltd have announced a joint research initiative to develop high-accuracy methods for evaluating the thermal diffusivity of silicon nitride ceramic substrates. This collaboration seeks to address the growing demand for reliable evaluation techniques for thinner substrates, which play a crucial role in power semiconductor modules used in electric and hybrid vehicles.

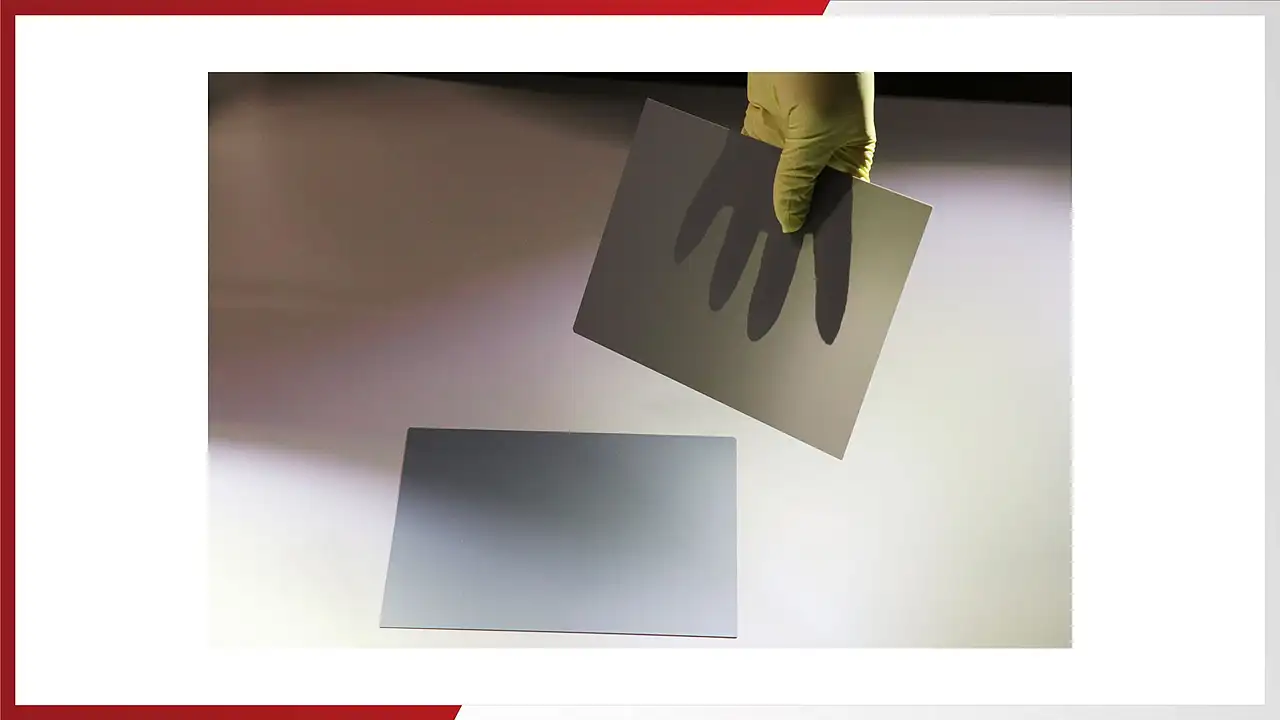

Silicon nitride ceramic substrates are integral to Active Metal Brazing (AMB) substrates, essential for heat dissipation in power modules like inverters for EVs and HEVs. As demand increases for thinner substrates with superior thermal diffusivity to enhance the operational efficiency of power semiconductor modules, challenges have emerged in consistently measuring the thermal diffusivity of materials less than 0.5 millimetres thick. Existing standards, such as the Japanese Industrial Standards (JIS), do not adequately define methods for these thinner substrates.

The collaboration leverages AIST’s expertise in advanced evaluation methods and NGK’s ceramic substrate technologies. Together, the organisations aim to generate reliable data to validate evaluation processes for thin substrates. This research will contribute to standardising methods for high-performance thin ceramic materials, improving measurement accuracy and reproducibility.

NGK’s advanced ceramic technologies, including its proprietary bonding techniques for AMB substrates, have significantly reduced thermal resistance and enhanced thermal dissipation in power modules. These advancements are critical for addressing the rising demands of electric and hybrid vehicles, where efficient heat management is a priority.

AIST, through this initiative, seeks to standardise evaluation methods in the industry while bolstering Japan’s industrial competitiveness in the global market for electronic devices. The organisation aims to develop solutions that align with global sustainability and technological advancement goals. NGK, a leader in ceramics manufacturing since 1919, sees this partnership as an opportunity to enhance the reliability of its AMB substrates and support societal needs with cutting-edge technology.

With its focus on mobility, energy, and IoT, the company continues to innovate with ceramic-based solutions that reduce environmental strain, such as its NAS energy storage systems and EnerCera lithium-ion batteries.