Driven by the increasing adoption of welding robots in the automotive industry and industrial 4.0 fuel the demand for industrial robots, the robotic welding market size is estimated to register a CAGR of 14.5% from 2021 to 2028.

According to the new market research report - Robotic Welding Market Forecast to 2028, published by The Insight Partners, the global robotic welding market was valued at $ 4.4 billion in 2021 and is projected to reach $ 11.32 billion by 2028.

ABB, Fanuc, IGM Robotersysteme, Kawasaki Heavy Industries, Kuka, Nachi-Fujikoshi, OTC Daihen, Panasonic Corporation, Novarc Technologies and Yaskawa America are among the key players in this space.

As per the report, governments in the Asia Pacific have committed to using a WGA to implement Industry 4.0 and the overall digital transformation of society, although the degree and process of WGA vary across countries.

The 2020s will be pivotal for Asia Pacific countries in the digital society journey. The growing emphasis on intelligent connectivity will play many crucial roles in enhancing societies and economies during this decade. This period also coincides with the COVID-19 pandemic, which will in part be defined by the accelerated shift to digital platforms for work and social activities and the realization of Industry 4.0. The Insight Partners noted.

The growth of the robotic welding market can be attributed to several government initiatives such as Make in India and Made in China 2025, and the robotic revolution. In addition, an increase in the adoption of automated systems in the automotive and electronics sectors, improved and safe working conditions, and technological advancements are projected to propel the robotic welding market growth.

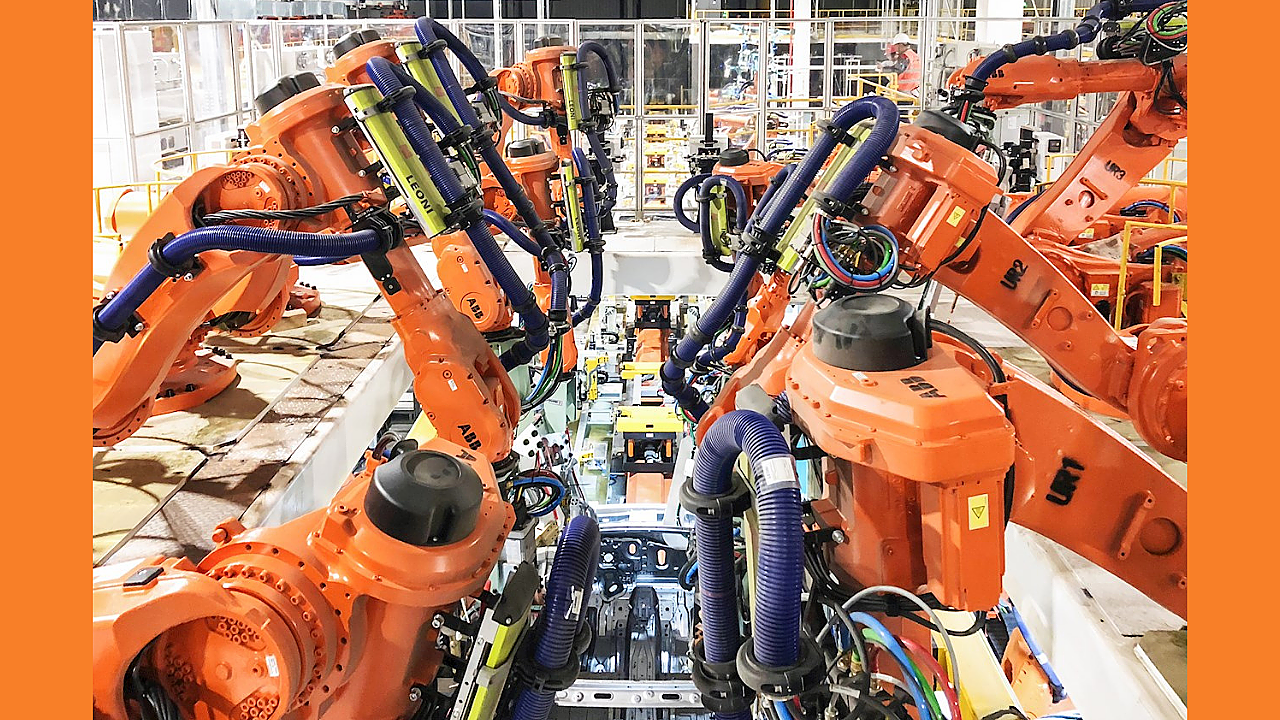

Based on end-user, the robotic welding market is segmented into automotive and transportation, electrical and electronics, metal and machinery, and construction. In 2021, the automotive and transportation segment led the robotic welding market and accounted for the largest market share, the report said.

Welding robots are a critical part of these industries' operations. The transportation industry turned to automated robot systems in the 1980s to improve their products and keep up with the increasing demand. The automotive manufacturing industry has long been one of the quickest and most significant adopters of robotic welding, which is driving the robotic welding market. Robots are used in nearly every part of automotive manufacturing in one way or another, and it remains one of the most highly automated supply chains in the world. Increasing demand for cars worldwide puts pressure on the transportation industry and automotive sector to raise production, thereby fueling the growth of the robotic welding market, The Insight Partners said.

COVID Impact

The emergence of the COVID-19 virus has impacted businesses' revenue stream and operations in the robotic welding market in Europe. Meanwhile, the demand from automotive end-users was at the lower side in 2020 and 2021, which affected the robotic welding market growth. However, non-automotive end-users such as electronics and metal and machinery end-users have showcased a positive trend in the adoption of welding robotics from Q1 of 2021, owing to ongoing skilled labour shortage, which positively influenced the growth of the robotic welding market from 2021, the industry research provider noted.

Courtesy: Insight Partners. NB: Photo is representational; courtesy: ABB.