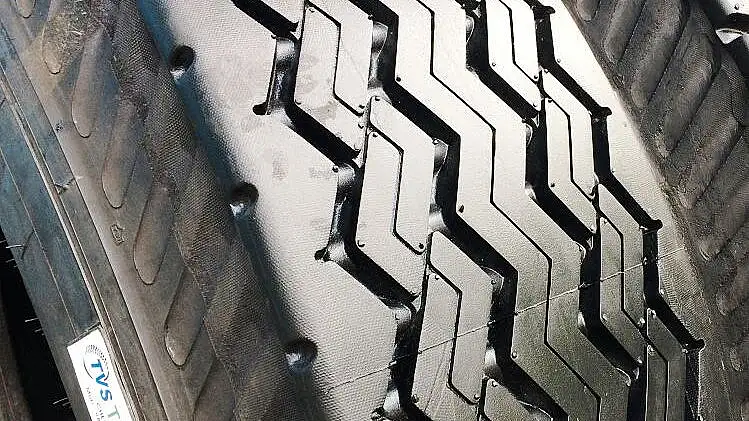

Retread tyres are sometimes known as recap tyres or remoulded tyres. Simply put, retread tyres are older tyres that are still structurally sound. Retreads have had their worn casings removed and given new treads and sidewall rubber fittings that are vulcanised to the casing. This is expected to extend the life of a tyre. Retreading tyres is a sustainable practice that helps to prolong the lifespan of tyres and reduces waste in the automotive industry. By replacing the tread, retreaded tyres can provide similar performance and safety characteristics as brand-new tyres but at a lower cost.

The automotive retreaded tyres market is estimated to grow at a compounded annual growth rate of 5.87% between2023 to 2028. The market is projected to increase by USD 3.11 billion, according to a report by Technavio, a leading market research company. The global automotive retreaded tyres have several advantages.

These are both functional and cost-related, and, hence, retreaded tyres are popular among commercial vehicles, especially heavy commercial vehicles.According to the report, a host of factors define the growth of the retreaded tyre market. Among others, its growth depends on the cost advantage of retreaded tyres, energy conservation and environmental benefits of using retreaded tyres and the increase in demand for medium and heavy commercial vehicles.

Cost Advantage

“Retreaded tyres have succeeded in delivering measurable value to users with a high-value proposition. The foremost driving factor behind the rising demand and popularity of retreaded tyres has been the cost advantages associated with them.

As an old and used tyre is used for the retreading process, retreaded tyres cost significantly less and are affordable in comparison to brand-new tyres,” the report said. Retreaded tyres cost almost 50%-65% less than the total cost of a brand-new tyres, making it much more affordable, especially for fleet operators who need to change tyres regularly.How is it possible?

Well, this is mainly possible due to the limited use of rubber compounds, which reduces the high dependency on rubber resources. According to the US EPA, retread tyres contain up to 75% post-consumer recycled material. Every retreaded tyre saves over 40 pounds of raw material, including rubber, steel and carbon black.Why is it that retreaded tyres are sought after?

The reasons are simple. For, retreaded tyres help to save on maintenance and replacement costs with warranty schemes. All prominent retreaded tyre manufacturers provide some form of warranty each time a tyre is retreaded. This reduces the cost of potential failure. All these factors are expected to increase the demand for automotive retreaded tyres, which will propel the growth of the global automotive retreaded tyre market during the forecast period, the report said.

Growth Drivers

A host of factors define the growth of the retreaded tyre market. Among others, its growth depends on the cost advantage of retreaded tyres, energy conservation and environmental benefits of using retreaded tyres and the increase in demand for medium and heavy commercial vehicles.

Prominent players in the field of automotive retreaded tyres are: Bridgestone Corp, CIO Tyres Pvt. Ltd., Continental AG, Eastern Treads Ltd., JK Tyre and Industries Ltd., Kal Tire, KRAIBURG Austria GmbH and CO. KG, MARANGONI Group, Michelin Group, MRF Ltd., Nokian Tyres Plc, Oliver Rubber Co., RDH Tire and Retread Co., REIFEN HINGHAUS GmbH, ROSLER TYRE INNOVATORS, The Goodyear Tire and Rubber Co., Tyresoles, West End Tire, Yokohama Rubber Co. Ltd. and Parrish Tire Co.

North America Leads

Based on geography, the market is classified as North America, APAC, Europe, South America, Middle East and Africa. North America is estimated to contribute 35% to the growth of the global market during the forecast period. The US, Canada and Mexico are the major contributors to the regional automotive retreaded tyre market. “Some of the main factors driving the market for vehicle retreading in this region are improved tread durability, increased supply of rubbers, rising labour costs and a lack of skilled technicians,” the report said.

Market Segmentation

Based on product, the market is classified into Pre-cure and Mold-cure. The Pre-cure segment is estimated to witness significant growth during the forecast period. The process where the new tread rubber is affixed to the tyre casing by applying it with special curing is referred to as Pre-cure retreading. In comparison with other retreading techniques, this segment has gained momentum because of its wide range of benefits and advantages.

Courtesy: Technavio. Photo is representational, courtesy: TVS Tread.

Also Read

Automatic Tyre Inflation System Market To Reach $ 2029.9 Million By 2025