Rising fuel prices coupled with the growing awareness about environmental protection have been driving the adoption of electric vehicles and, subsequently, the demand for electric HVAC compressors. According to a study conducted by Grand View Research, these factors drive the global automotive electric HVAC compressor market to reach $ 38.31 billion by 2028, registering a CAGR of 20.7% from 2021 to 2028.

However, the US-based market research firm finds that high initial costs and maintenance costs associated with electric HVAC compressors are expected to restrain the market's growth.

The installation of electric HVAC compressors involves heavy-duty electric wiring, which increases the overall cost of the system. Furthermore, repairs and maintenance of electric compressors is also a complex task requiring a high level of expertise, thereby adding to the overall cost.

Moreover, the demand for electric compressors relies entirely on the demand for electric vehicles. However, the sales of electric vehicles are already facing a double whammy of the higher price and range anxiety associated with electric vehicles. Nevertheless, advances in technology, the subsequent launch of new products, and the continued installation of electric chargers and charging stations are expected to encourage consumers to opt for electric vehicles, thereby driving the demand for electric HVAC compressors over the forecast period, Grand View Research stated.

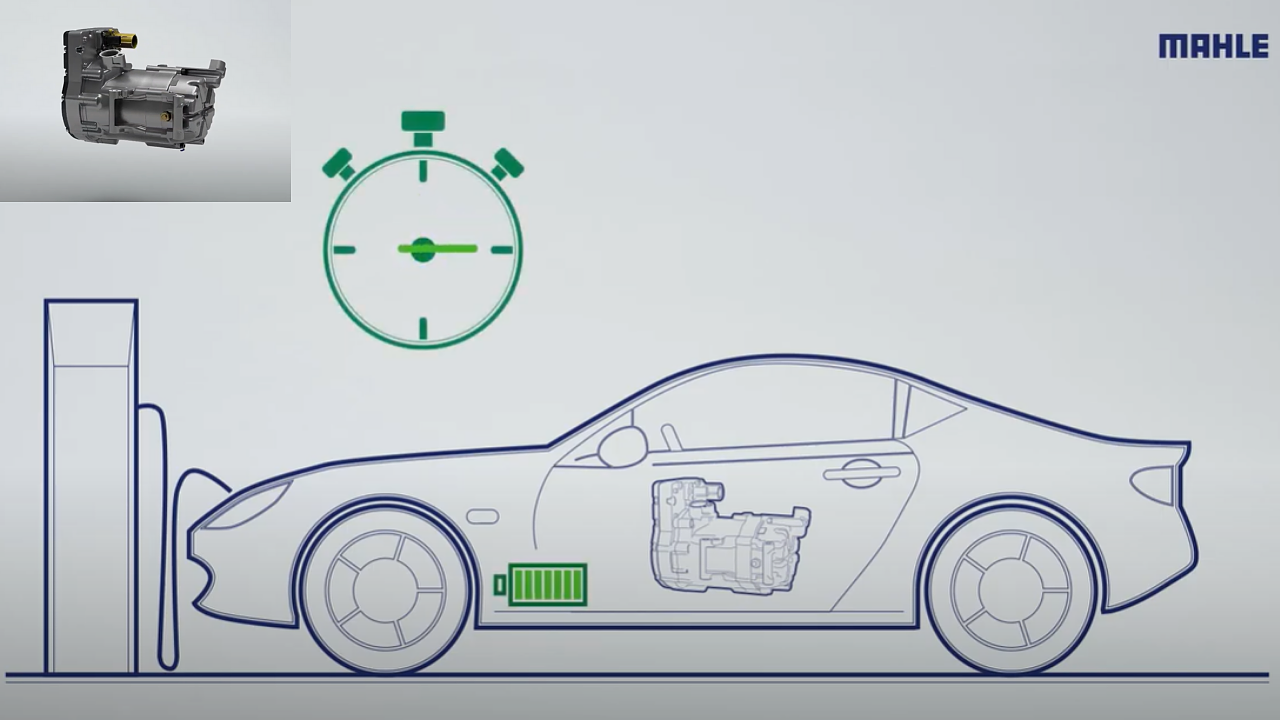

The function of an electric compressor in an electric vehicle is much significant than that of a conventional compressor in an ICE vehicle. In an EV, the compressor is responsible for the cooling of the entire cabin and the battery pack. Electric compressor protects the battery from overheating and, subsequently, the vehicle from breaking down. Hence, an electric HVAC compressor serves as an essential component for the overall functioning of an EV.

Benefits

An electric compressor offers several benefits over a conventional compressor, such as lower energy consumption, compact size, controlled revolution speed, and noise-free operations. Unlike a belt-driven conventional compressor, an electric compressor is independent of the vehicle's engine. The electric compressor draws power from a separate electric motor, which is powered using an inverter. Such an arrangement ensures that the cooling operation of the vehicle continues even when the vehicle is turned off. The electric compressor also requires less power to drive due to this arrangement, leaving the vehicle performance unaffected and ensuring cleaner operations due to low oil carryover.

Dominant segment

According to Grand View Research, the 20-40 CC segment dominated the market in 2020 with a revenue share of 48.3%. Besides, the segment is expected to continue its lead over the forecast period. The growth can be attributed to the fact that compressors with a 20-40 CC cooling capacity are usually installed in small and medium vehicles, which have a high adoption rate.

The passenger vehicle segment is expected to register the highest CAGR of more than 20% over the forecast period. The growth can be attributed to the growing adoption of electric passenger vehicles for personal use, corporates, governments and defence agencies.

The battery-electric vehicle segment is expected to register the highest CAGR over the forecast period. The growth can be attributed to the increasing demand for electric vehicles in line with the continued rollout of charging infrastructure and prompt availability of skilled technicians to service electric vehicles.

The Asia Pacific is promising owing to the rising adoption of EVs

The Asia Pacific regional market is expected to witness significant growth over the forecast period in line with the increasing adoption of EVs across China and other developing countries in the Asia Pacific region, the research firm said.

Courtesy: Grand View Research. NB: Photo is representational; courtesy: MAHLE.