The electric motor has been around for more than a century. With lesser moving parts and the efficiencies already at the highest levels, is there an option to enhance the efficiency further? Defying many nay-sayers, technology company ZF reiterates that it is possible and has walked the talk too.

With its high level of interface expertise and unique know-how for driving strategies, the technology developers could meet customer requirements to a large extent in the best possible way. However, the group also offers innovative components based on its system solution.

New Winding Approach

Is there a connection between the hair styling of women and an EV? It looks so, as the copper coil winding in the electric motor seems to have a semblance.

In stators and rotors of electric motors, coated/ varnished copper wires are wound within coated flexible iron magnetic cores to shape magnetic poles and are strengthened with the current.

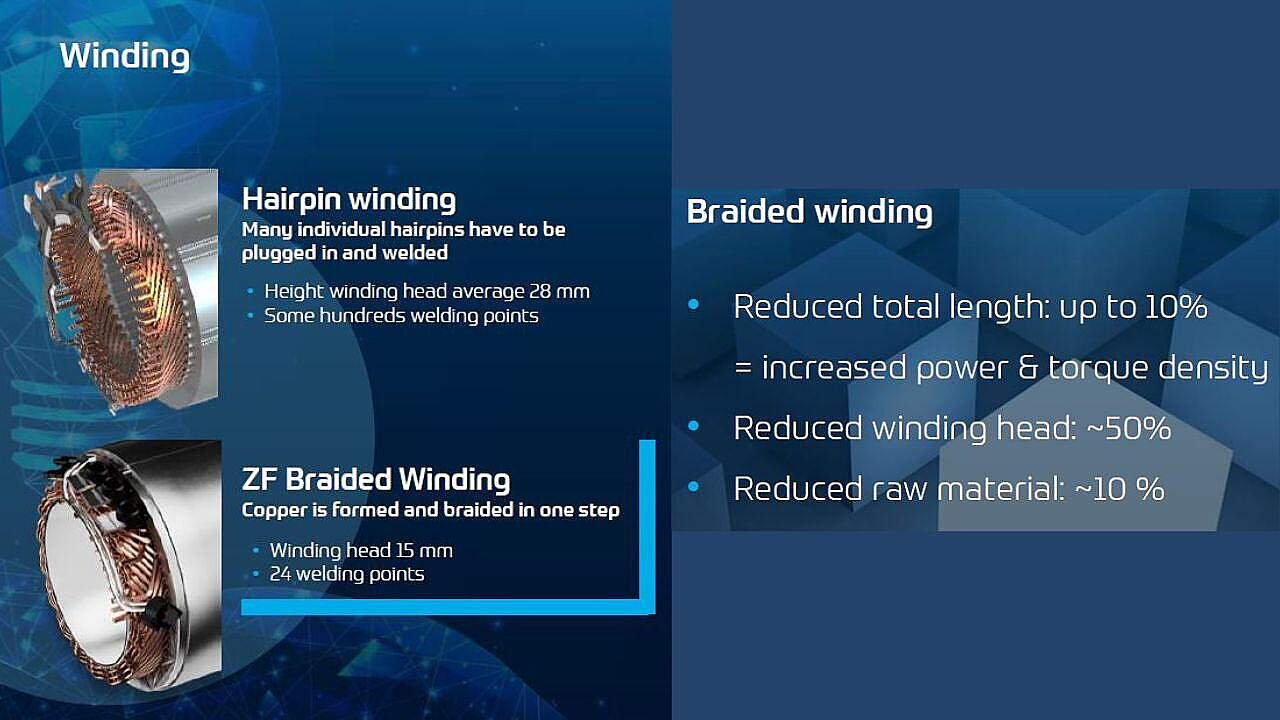

Some of the windings include squirrel cage (cylindrical core), lap winding (connecting lanes and poles), wave winding (parallel lanes), etc. Subsequently, hairpin winding became popular, especially in automotive applications, where solid conductors have higher fill factors (packaging) thank the stranded wires.

Here, many individual copper hairpins must be plugged in and welded in 200-plus points. However, a certain portion of the winding pops out from the stator with the height winding head averaging about 28 mm, affecting on two counts – ineffective cooling of that portion of winding, and also the unproductive winding, i.e. the portion of the coils outside the core, is not efficiently used.

ZF has been following hairpin technology for the past seven years. However, to address the issue of hairpin winding, the Germany-headquartered company has developed a braided winding, resembling a woman’s braid, addressing both concerns of hairpin winding. The braided winding technology developed by the company is a further development of the hairpin winding, reducing installation space by up to 10%. In addition, the winding head alone is around 50% smaller than the conventional approach. Therefore, it translates into processing around 10% less raw material.

Roland Hintringer, Head of Product Line, E-Motors, ZF, said the wires would be braided and inserted into the stator much more easily than hairpin winding. Secondly, unlike the hairpin coils that need welding, the braided winding welding spots will be around 20. Besides, it can reduce the winding head by 50%, as the winding head is not contributing to any power or torque. This helps in reducing power density, cost and installation space, he said.

According to Hintringer, the braided winding can help reduce the total length of the e-motor by 10%, which will eventually help increase torque and power density.

To a query on the advantages of braided winding, Hintringer told this publication that hairpin winding is a technology that needs a complex manufacturing process and increased floor space, which is well addressed in the braided winding. In braided winding, six or eight or more single-strand thin copper wire is braided, which enables it to be much more precise in production. “There is no major risk,” he said.

Innovative Cooling Technology

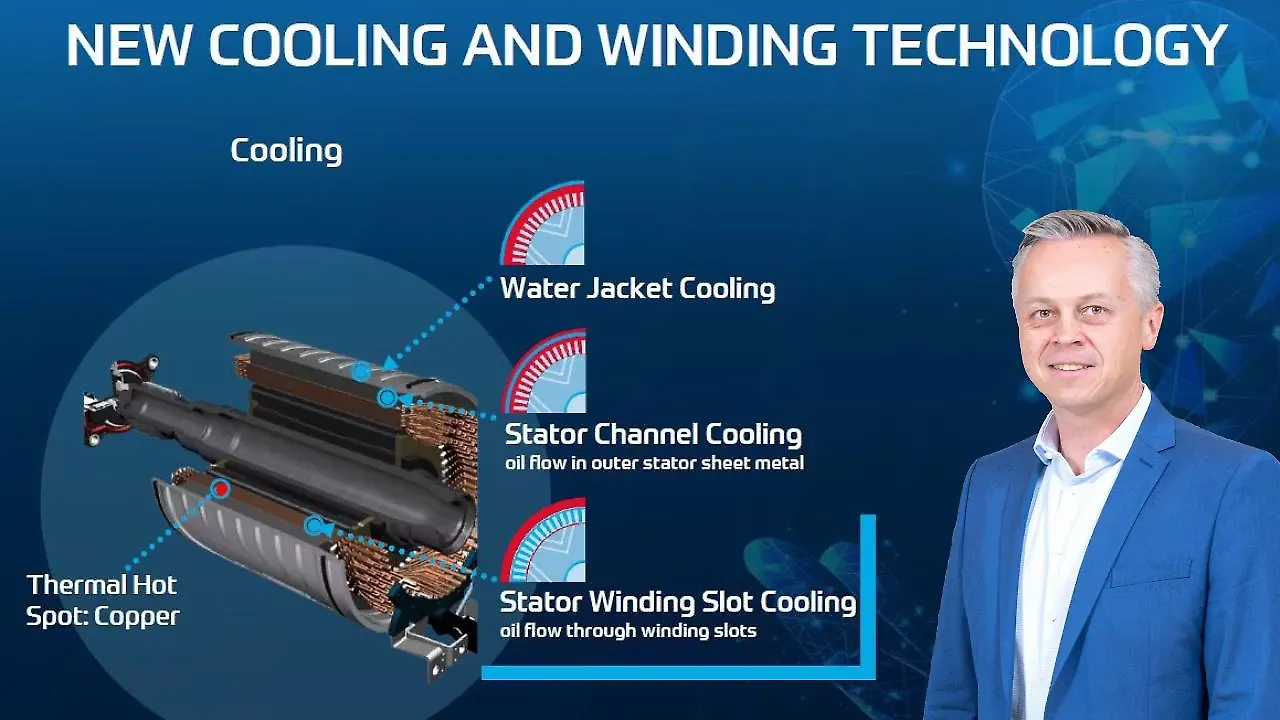

With a new, highly integrated e-motor, the technology company has increased its power density compared to the technology currently available in the market. In the conventional cooling system, water flows through the outer side of the stator. The next stage, according to Hintringer, is the channel cooling on the winding itself, which is the heating source.

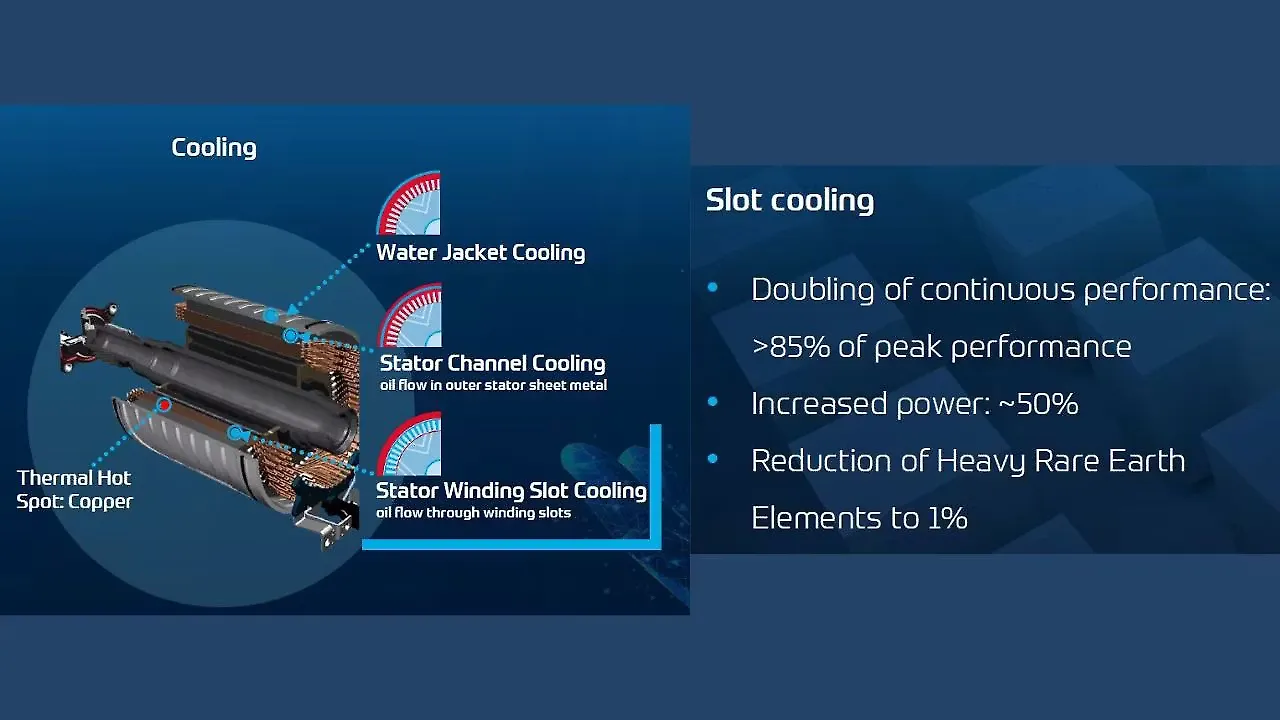

By using oil instead of water, the cooling channel is placed through the laminated stacks. The oil will flow through the slots in the electric motor, trying to absorb the heat from the source itself.

The new cooling concept and a new winding technology play a decisive role here. Thanks to the new cooling concept, ZF allows oil to flow directly around the copper rods - exactly at the point where most heat is generated during operation. The efficient cooling significantly increases performance with the same weight and installation space. This, according to him, will double the continuous performance of the new-gen motor, which will be more than 85% of the peak performance compared to the conventional motor. It also helps in better acceleration. Besides, it will increase the power by about 50% for the same installation space and reduce the heavy rare earth materials to 1%.

“The more you cool the motor the less rare earth material you use. Heavy rare earths are added to magnets to make it stable to temperature,” he said. Having a good cooling system will minimise the requirements of rare earth, which significantly helps in accomplishing sustainability targets, he noted.

Speaking on the advantage, he said the continuous power of the electric motor is increased to up to 85% of the peak power. In addition, the use of heavy rare earth can be largely dispensed with, and the e-motor can thus be produced more sustainably.

“Though electric motors are quite efficient already, we try to squeeze out each and every percent of additional efficiency and being able to range the electric vehicle even more,” Hintringer said.

With braided winding and innovative cooling, the motors can be made even more sustainable, not only in terms of the new design but also in the recycling concept and use of lesser materials.

Asked about servicing the motors, Hintringer said de-assembling the stator and the rotor is a major challenge due to heavy magnets. This is the highest priority for the service personnel. Braided winding can help address this issue besides facilitating recyclability, he added.

Also Read:

ZF Bets Big On India In Global Electric Transition

ZF Surpasses Two Million Production Mark For Electric Motors