Veejay Nakra, President of the Automotive Division at Mahindra & Mahindra, identified untapped opportunities in the sub-3.5-tonne LCV segment, a space where the company was underrepresented.

His vision was to leverage these gaps to boost Mahindra's overall market share, which currently stands at an impressive 63.1% in this category. In certain sub-segments, Mahindra enjoys an overwhelming dominance of 80%, while others show room for growth with a more modest 23% share.

To turn this vision into reality, Prathap Bose, Chief Design and Creative Officer at Mahindra & Mahindra, brought his design prowess to the table. His goal was to create vehicles that seamlessly blended functionality with aesthetics, evoking a sense of pride and dignity for the drivers behind the wheel.

On his part, R Velusamy, President of Automotive Technology & Product Development, led the engineering charge, tasked with transforming Nakra's ambitious dream into reality. Nakra sought to offer an array of vehicles spanning various gross vehicle weights (GVWs), load body configurations, and energy sources.

To meet this diverse set of requirements, Velusamy and his team adopted a modular platform, allowing for the flexibility needed to cater to such a broad spectrum. At the Mahindra Research Valley, the team meticulously pieced together the puzzle, designing a versatile frame and cabin that could accommodate a wide range of applications. The outcome of their combined efforts was the creation of the Veero—a vehicle designed to redefine the sub-3.5 LCV segment with adaptability and innovation.

Next-Generation Modular Platform

In a recent conversation with Mobility Outlook, Velusamy highlighted the cutting-edge engineering behind Mahindra’s next-generation modular platform. At its heart lies a high-strength steel frame, engineered to deliver exceptional load-carrying capability and stability. This robust framework serves as the backbone of the vehicle, designed to support a range of versatile configurations without compromising on strength or durability.

The beauty of this modular design lies in its adaptability. The core frame remains constant, allowing for the seamless interchangeability of key components like tyres, suspension systems, engines, rear axles, and propeller shafts. This flexibility enables Mahindra to offer multiple cargo configurations across diesel, CNG, and electric powertrains. “With 14 cargo body options, four tyre sizes, and five wheelbase variants, Veero redefines the standard for modular, multi-energy commercial vehicles,” Velusamy remarked.

Built to surpass customers’ expectations, these vehicles undergo rigorous testing, withstanding loads double the industry standard. The frame itself boasts twice the bending and torsional strength of its nearest competitors, ensuring structural integrity. Additionally, the cabin has been meticulously designed for enhanced safety, offering three times the bending rigidity and four times the torsional rigidity of its industry counterparts. This ensures not only better protection for the driver and passengers but also enhanced safety in the event of a collision, making Veero a benchmark for strength, durability, and adaptability in the commercial vehicle segment.

Versatility In Every Detail

Veero offers multiple payload options across various wheelbase configurations, tailored to meet diverse commercial needs. With cargo lengths ranging from 2,765 mm to 3,035 mm, the vehicle is designed to accommodate a wide array of transport requirements. Its improved manoeuvrability, with a turning circle diameter as tight as 10.2 metres—18% smaller than its nearest competitors—makes it to navigate narrow and congested streets of urban environments with ease and precision.

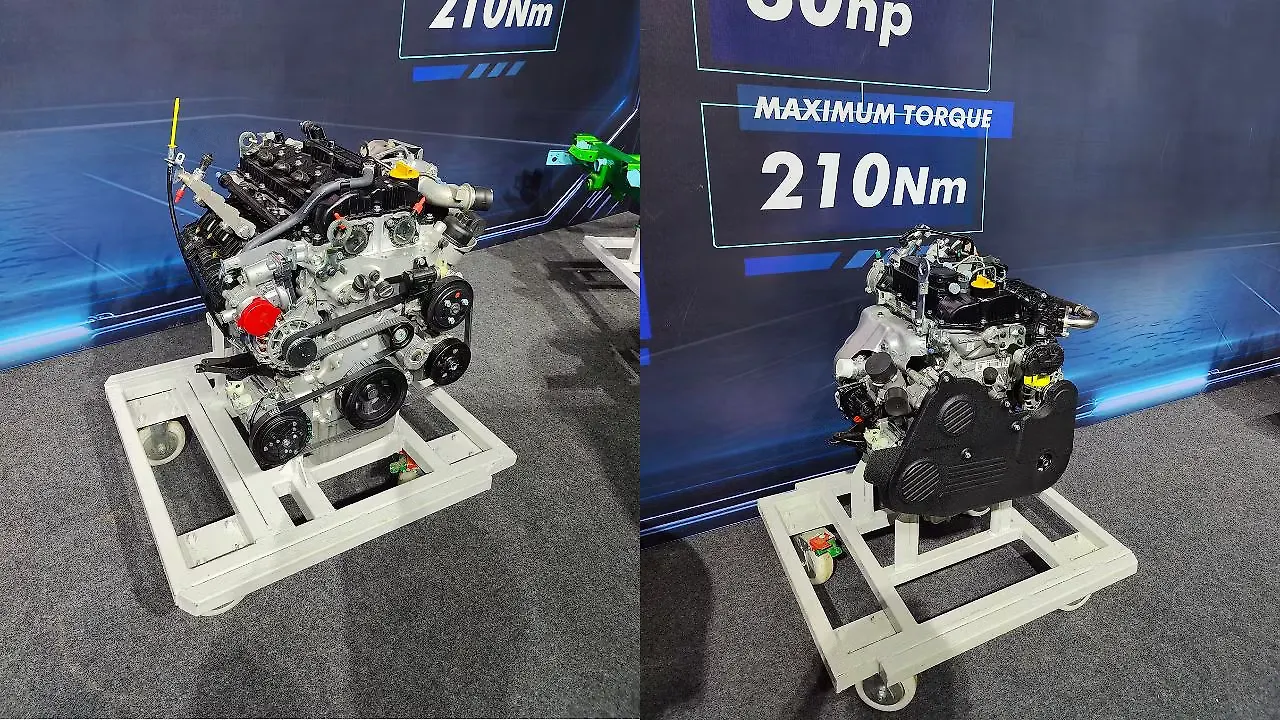

Performance, Efficiency

Veero’s performance lies a cutting-edge 1.5-litre engine, equipped with four valves per cylinder. This advanced engine delivers 18% more torque at just 1,000 RPM compared to its rivals, ensuring powerful low-end performance. The enhanced torque enables earlier gear shifts, significantly boosting fuel efficiency by up to 18%. This increase in fuel economy offers tangible savings, with drivers benefiting from an additional INR 10,000 in their pocket for every 10,000 km driven. This blend of power, efficiency, and cost savings positions Veero as a significant player in the commercial vehicle segment, offering businesses not just performance, but also long-term economic value.

Extended Service Intervals for Reduced Maintenance

Velusamy highlighted the company’s focus on durability and cost efficiency, stating, 'We engineered the Veero platform with an emphasis on stability and longevity. Its robust structure not only ensures extended tyre, brake, and steering life but also reduces overall maintenance needs.'

The vehicle is designed to go the extra mile, quite literally, with service intervals twice as long as the competition, with a minimum of 20,000 km between services. This extended interval translates to reduced maintenance costs and less downtime, keeping the vehicle on the road and operational for longer periods.

Safety Redefined

Velusamy explained that the vehicle's forward cabin is engineered to withstand impact forces five times greater than its peers, offering improved crash protection. In the event of a collision, the frame is capable of absorbing up to 155 kilojoules of energy—a first in the industry.

Complementing this innovative structure, the cabin is equipped with airbags, providing the driver with an added layer of protection. 'Our spacious cabin also prioritises driver comfort, with ample shoulder and legroom to ensure a fatigue-free driving experience,' Velusamy added.

In line with sustainability goals, Velusamy pointed out that Veero’s 18% improvement in fuel efficiency is a direct result of advanced engineering and technological innovation. The vehicle’s modular platform and the use of high-strength steel reduce its overall weight, while its diesel engine delivers 18% higher torque, optimising gear utilisation and further enhancing efficiency. This combination of weight reduction and improved torque results in optimal fuel consumption, aligning with the sustainability objectives of many of Mahindra’s customers.

CNG Engine Innovation

For the CNG variant of Veero, Mahindra introduced a turbocharger to enhance performance. This upgrade allowed the use of the same gearbox while improving overall efficiency, offering a seamless driving experience across multiple fuel options.

When discussing materials for the vehicle’s interior, Velusamy acknowledged the price-sensitive nature of the segment in which Veero competes. 'Total cost of ownership is critical in this market, so we had to be strategic. We couldn’t use the same high-end materials found in SUVs, but we made careful choices to ensure both durability and affordability,' he explained.

This attention to detail, across safety, efficiency, and cost management, makes Veero's position as a commercial vehicle that not only meets but exceeds the evolving needs of its users, offering cutting-edge performance while keeping operational costs in check, he added.

Also Read:

Mahindra Veero To Fulfill Customers’ Un-stated Needs Too: Pratap Bose