Automated driving and electrification drive brake systems to become more intelligent.

According to technology company Continental, the first flush of implementations will kick off in GenNext vehicles with a modified architecture. This will need better understanding to combine safety and sustainability in future brake systems.

In the long term, brake systems will become modular and distributed and here is where Continental, working closely with OEMs, is shaping the future of brakes. The company believes that global megatrends are leading to a change in vehicle architecture with powertrain electrification and the growing capabilities of automated driving (AD).

Digitalisation and connectivity are fundamentally realigning the electrical and electronic architecture (E/E architecture) of vehicles which is increasingly based on software. Eventually, it is this software that will define the character of cars and driving experiences in the future. Bytes will replace horsepower with apps and services pushing the car into becoming safer and more comfortable.

Future Brake Systems

This evolution will bring in radical changes in the long term. With digitalisation and connectivity, electric drives and AD capabilities, brake systems must fulfil additional tasks. Continental is, therefore, developing future brake system technologies (FBS), which are even more compact, lighter and cost-effective.

With multi-logic, they offer improved performance characteristics compared to MK C1. The MK C2 features two printed circuit boards and processors each that can uphold more functions in case of a fault. They enable the parking brake to be actuated redundantly, thereby eliminating expensive mechanical transmission locks for immobilising the vehicle. The company believes that the MK C2 evolutionary stage will form the basis for FBS due to its benefits.

FBS Level 1

According to Continental, FBS can lead to the transition to a complete brake-by-wire system. It has developed the MK C2D concept, a modularised and scalable system generation, comprising two independent actuators.

The MK C2D (D=distributed) can be used (as before) with a mechanical pedal, MK C2D mP (mechanical pedal — an FBS 0 system with hydraulic fallback mode by the driver and brake pedal), and also an electronic brake pedal, MK C2D eP (electronic pedal). In this case, like in highly automated driving (HAD) mode, the second actuator takes over in case of a fallback situation instead of the driver’s foot.

The MK C2D system generation is designed for AD following SAE Level 3 or higher. The platform uses existing components that have already proven themselves in the MK C2. Therefore, there are more possibilities for commonalities of parts between MK C2 and MK C2D eP.

Dennis Fritsch, Head of Active Safety and Controls segment, Safety and Motion, Continental, told Mobility Outlook that with MK C2D eP, the company makes the step from the MK C2 simulator brake system (that uses brake-by-wire in case of normal operation and the hydraulic fall back in case of a failure) to a full brake-by-wire system.

Fail-safe To Fail-operational

This means moving from a fail-safe to fail-operational system. In a rare case of failure, said Fritsch, the driver does not use his muscle force but a secondary redundant brake system. This has already been in production at Continental for highly automated driving (HAD) SAE L3 to L5 where a “virtual driver” is in charge of braking.

The step towards an electronic brake pedal system was the next developmental step and resulted in new flexibility with respect to packaging and easier assembly of the brake pedal and brake system. In addition, with the removal of mechanical and electrical parts of the pedal actuation unit from the MK C2D eP, the system complexity and weight was reduced.

“Overall, the fail-operational brake system MK C2D eP has improved brake performance after the first failure and fully supports HAD. One step further towards our Vision Zero,” Fritsch added.

From the user's point of view, will the new braking system be risky as the driver will not be active most of the time? He says HAD poses tough requirements to the braking system. Should the primary electronic brake system fail in a very unlikely rare case, the secondary electronic brake system will step in and provide the required braking function.

“This means, with an MK C2D eP, if the primary brake system fails, the HAD system can calmly give back to the driver as the redundant, secondary brake system is available,” explains Fritsch.

The complete separation of pedal and pressure generation without fallback mode is a huge advantage for integration and characteristic of real brake-by-wire systems. This leads to a new setup in the system as it no longer needs to be mounted directly at a specific location on the firewall in front of the driver to enable mechanical fallback.

Instead, an FBS 1 with an electronic pedal supports new vehicle concepts involving different interiors and dimensions, such as the skateboard chassis of electrified vehicles, on which various bodies can be mounted.

Semi-dry Brakes

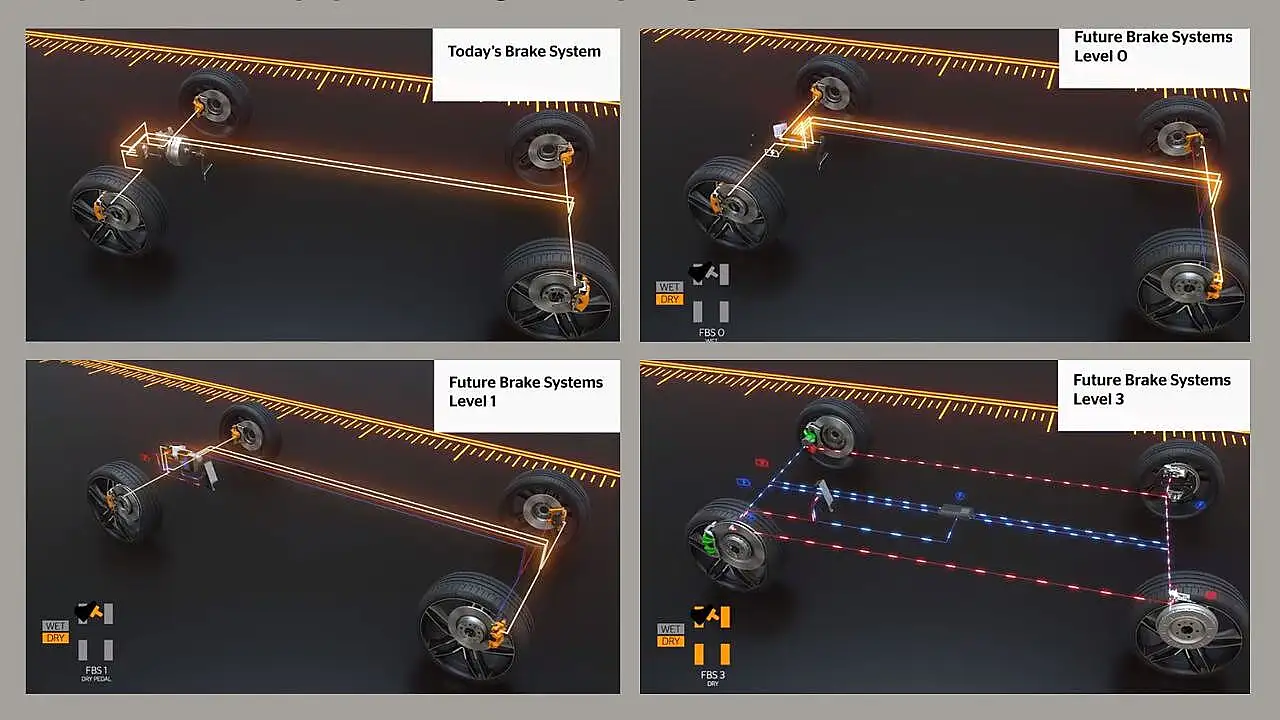

In today’s brake systems and FBS 0 and FBS 1 solutions, pressure generation is still fully integrated into the unit. The hydraulics, which is the ‘wet’ part of the system, transmit the force to the brake callipers of the disc or drum brakes. However, the more E/E and vehicle architecture evolve, the more attractive it becomes to eliminate this inflexible ‘one-box arrangement’.

The new FBS does away with hydraulic brakes on the rear axle, as the fluid must be changed and disposed of regularly. Moreover, if the brakes were actuated electromechanically, installation of the rear axle would be simplified because rigid hydraulic lines could be dispensed with. At the same time, the hydraulics on the front axle would still be available as a fallback system.

Hence, the rear axle wheel brakes are operated electromechanically, i.e., ‘dry,’ which could be used for systematic energy recuperation during each braking operation. Once the rear axle brakes become independent of the hydraulic system, they provide the ideal conditions for this. This would require a certain degree of “intelligence” in the brake system. This decentralisation and “breaking-up” of the conventional architecture would further increase the degree of freedom for vehicle architectures.

Death Knell For Hydraulics?

According to Continental engineers, the hydraulic system can be eliminated in the long term, and to achieve this, all four-wheel brakes can be actuated electromechanically and turn completely “dry.” The current focus on pressure generation and modulation with appropriate control intelligence will no longer be necessary.

FBS helps eliminate many parts, including hydraulics and related champers leading to weight savings. According to Fritsch, a completely dry brake system saves a lot of weight compared to a conventional system. (It is important to note what is being compared with each other and that there is still no series design of a dry brake system).

“Weight savings in the low kilogram range can be achieved, for example, by eliminating the brake fluid and brake fluid lines,” he said. In this case, the typical FBS3 brake system consists of the four dry wheel brakes (callipers or drums) and a series of software function blocks.

For reasons of safety and redundancy, they can run on several of the existing high-performance computers with integrated wheel control units, providing the redundancy required for safety. To make this long-term transformation to FBS3 possible, the brake system's individual functions must be encapsulated as stand-alone products in modular, validated and proven software blocks. These can then be integrated into various vehicles thanks to standardised interfaces based on the principle of re-use.

According to Continental, the motion functions remain the cornerstone of active driving safety, and this is more so with the brake systems. At the same time, however, the general conditions for motion control functions are changing significantly due to the new E/E architecture and vehicle capabilities such as AD.

The company is seeking to exchange ideas with vehicle makers, which will help shape the further development of brake systems. This is key as the advantages of future systems will be less significant for brake functions than for the vehicles themselves.

Also Read:

New Continental, Nisshinbo Plant To Ramp Up EBS localisation