Valeo India, the Indian arm of the global automotive technology leader Valeo, is making bold strides in supporting automotive OEMs by developing cutting-edge local technologies and solutions. As part of its ambitious plans, the company aims to invest INR 200 crore in the coming years to enhance its R&D capabilities, according to Jayakumar G, Group President and Managing Director of Valeo India.

Strengthening R&D for Self-Sufficiency

The company’s Tech Centre is currently working across ten disciplines, including Mechanical Design, Simulation, Embedded Software Development, Vision Systems Software and Hardware & Functional Safety Design. The Development Test Lab provides testing and failed part analysis services to Valeo sites across the globe, supporting Valeo’s Business and Product Groups. This test lab in Chennai also supports the Group to locally design and develop solutions for Valeo’s Indian customers. “The additional investments will focus on developing infrastructure, including labs, to support the diverse disciplines managed by the R&D centre,” he said.

“Over the last three years, we have significantly enhanced our infrastructure by adding new labs and essential equipment,” Jayakumar shared. “Previously, engineering tasks were conducted in India, but prototypes had to be tested in Europe or elsewhere. Today, we are becoming self-sufficient, with the ability to handle engineering work, prototyping, testing, and software development entirely within India.”

Valeo India’s R&D team has a strong focus on advanced driving assistance systems (ADAS) and electrification, supported by a workforce of over 1,500 software specialists. To address niche skill shortages, the company established a satellite R&D centre in Bangalore last year, housing around 250 experts in areas like cybersecurity, complementing its Chennai operations.

A Legacy Of Innovation, Adaptation

Valeo’s journey in India began in 1997 with a modest operation focusing on clutches. Over the past 25 years, the company has expanded its portfolio to include lighting systems, electrical solutions, HVAC systems, and, more recently, ultrasonic sensors. While historically centred on internal combustion engine (ICE) technologies, the last two years have seen a decisive pivot towards electrification and ADAS.

“Three years ago, the ADAS market in India seemed uncertain. Today, it’s poised for rapid growth, driven by evolving regulations and increasing demand,” Jayakumar noted. Technologies that were once niche, like ultrasonic sensors for high-end cars, are now mass-produced. Valeo currently produces two million ultrasonic sensors a year in India and has ramped up the annual capacity to five million units at its Sanand facility.

Comprehensive Presence Across India

With 7,000 employees in India, including 3,500 R&D professionals, Valeo operates eight production sites, one global R&D centre, five distribution platforms, and a front office serving clients across the country. These facilities are spread across Chennai, Pune, Sanand, Noida, and Gurgaon. Chennai remains the hub for clutches, friction materials, and lighting, while Pune focuses on thermal systems and electrical solutions, and Sanand specializes in ultrasonic sensors.

Pioneering Electrification

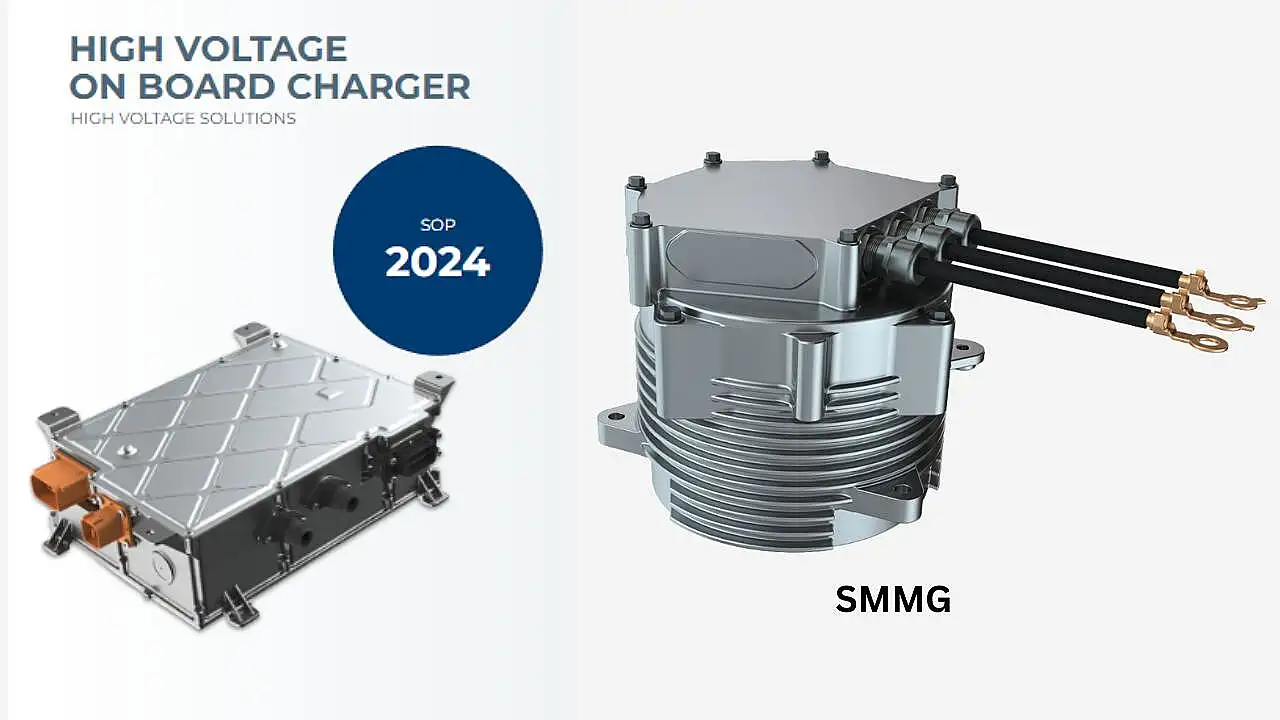

In addition to supplying starters and alternators for ICE vehicles, Valeo is at the forefront of electrification with innovations like 48-volt motors for two- and three-wheelers. The company has also introduced a high-voltage three-in-one combo for electric cars – HV Combo DCDC Gen4 OBC, integrating an onboard charger, DC-DC converter, and power distribution unit. This technology reduces packaging, weight, and cost, making electric vehicles more accessible. Notably, Tata Motors and Mahindra’s utility vehicles have adopted Valeo’s integrated systems, which are on track to achieve over 50% localisation.

Expanding Into New Segments

Traditionally focused on passenger and commercial vehicles, Valeo has ventured into the two- and three-wheeler segments over the past two years. Collaborating with major players like Hero, TVS, Atul, and Royal Enfield, as well as engaging with startups, Valeo is diversifying its footprint and leveraging India’s competitive supply chain.

Innovating For The Future

Valeo is set to showcase a groundbreaking software solution at CES 2025 in Las Vegas, designed to optimise battery thermal management based on driving conditions, weather, and user preferences. This innovation can extend battery range by 10-20%, allowing OEMs to either enhance vehicle range or downsize batteries, reducing costs. “By localising production in India, we aim to make these advanced technologies affordable and accessible, supporting the evolution of sustainable mobility,” Jayakumar concluded.

Also Read:

Valeo Expands Electrification Efforts With New Production Facility In Pune