Automotive battery manufacturer Trontek is planning to build its first mega plant in Delhi NCR, with a capacity of 2gWh per year, reveals Samrath Kochar, Founder and CEO of the company, during a conversation with Mobility Outlook.

The INR 50 crore plant is expected to be operational in 2025, with construction beginning in the middle of 2023. The company currently operates two facilities in Kundli, Haryana, with a combined capacity of 0.6 gWh.

Kochar added that 1.5 lakh e2w batteries and 20,000 e3W batteries were sold in FY23, for a total capacity of 0.6 gWh in the fiscal. Due to demand, the company expects to grow to 0.7 gWh of batteries in FY24. 'Volumes are likely to remain unchanged or minimal growth can be seen in the current fiscal year. However, we expect a marginal growth of 10-15%,' he added.

The CEO stated that by the time the new plant is operational, the company plans to add 0.4gWh capacity to its existing plants within the next year. He added that the three plants will concentrate on e2W and e3W batteries for now.

Changing With Time

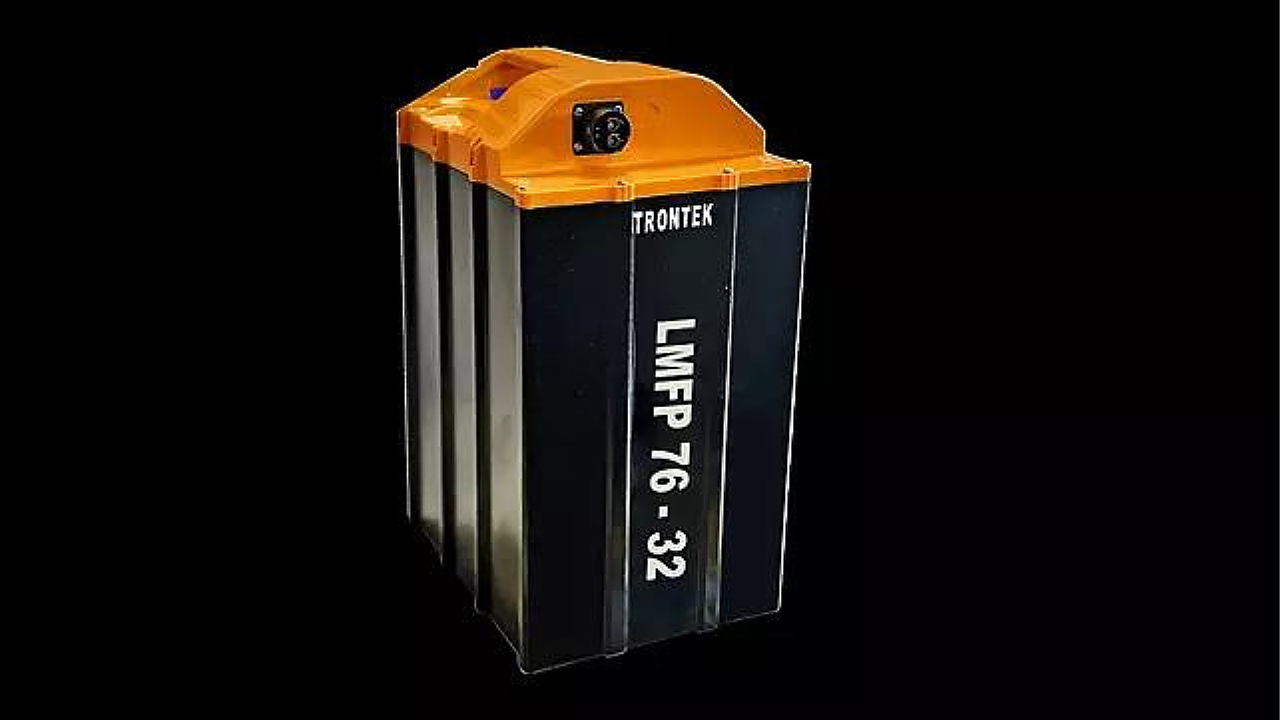

The company's journey began in 2004 as a battery manufacturer for UPS solutions, and in 2012, it ventured into lead-acid batteries for e-rickshaws. It introduced lithium-ion batteries for e3Ws and e2Ws in 2017. While in 2022, the company introduced LFP technology, with batteries ranging in capacity from 1.5 kWh to 3.64 kWh for e2Ws and 5.35 kWh to 10.7 kWh for e3Ws.

With cells imported from China, the CEO noted that the LFP batteries support the company’s proprietary design. The company has added heat sinks to the battery pack to manage heating issues, in addition to audio-visual warning systems and IPX7 rating, as well as smart BMS and Smart CAN-enabled chargers, which are designed in-house.

While the initial sales ratio between the NMC and LFP batteries was 80:20, the ratio has now shifted to 20:80. Kochar stated that when LFP batteries were introduced, the company began converting its batteries to make them compatible with AIS 156 phase II standards.

Currently, 80% of the company's product line is compliant with the new norm, while the rest 20% will be made compliant by the end of May 2023. The AIS 156 phase II certification requires strengthened safety in three key areas of the battery pack: cell, BMS, and pack design. It also addresses the onboard/offboard charger, broadly covered by the AIS 156 and AIS 038 Rev.2 standards.

As all of its products comply with the new standard, the company intends to expand into EV charging stations and a battery swapping network, Kochar confirmed. Currently, the R&D team is working on the AIS phase II norms, and he believes that work on EV charging and battery swapping stations will begin in the next quarter of FY24 and will reach the pilot stage, for testing in the Delhi NCR, by December 2023.

Dependence On China

During the conversation, the CEO mentioned that while most of the components used in its batteries are sourced locally, the cells are sourced from China. While cells from Korea and Japan are too expensive and will disrupt the company’s revenue model, the cell plants in Europe can only cater to domestic needs as of now. So as a battery manufacturer, the company is left with no other option than China.

Speaking on the cell manufacturing capabilities in India, Kochar believes that the ecosystem will only mature after six to seven years when cells for mass production can be sourced from India. He noted that while the work on cell manufacturing in India has already begun, it will take at least three years to get into pilot testing for these cells.

Also Read