Madras Engineering Industries (MEI) has recently joined the ranks of Volvo Group Truck’s exclusive fossil-free supplier club, marking a significant milestone in its journey towards sustainability. With the establishment of a dedicated foundry that produces exclusively green castings, MEI is poised to lead the charge in eco-friendly manufacturing. Currently, only half of the foundry’s capacity is utilised for exports, leaving substantial room for growth. This presents MEI with immense opportunities to expand its reach, supplying green brake systems to original equipment manufacturers (OEMs) across the globe, and further solidifying its position as a leader in sustainable automotive solutions.

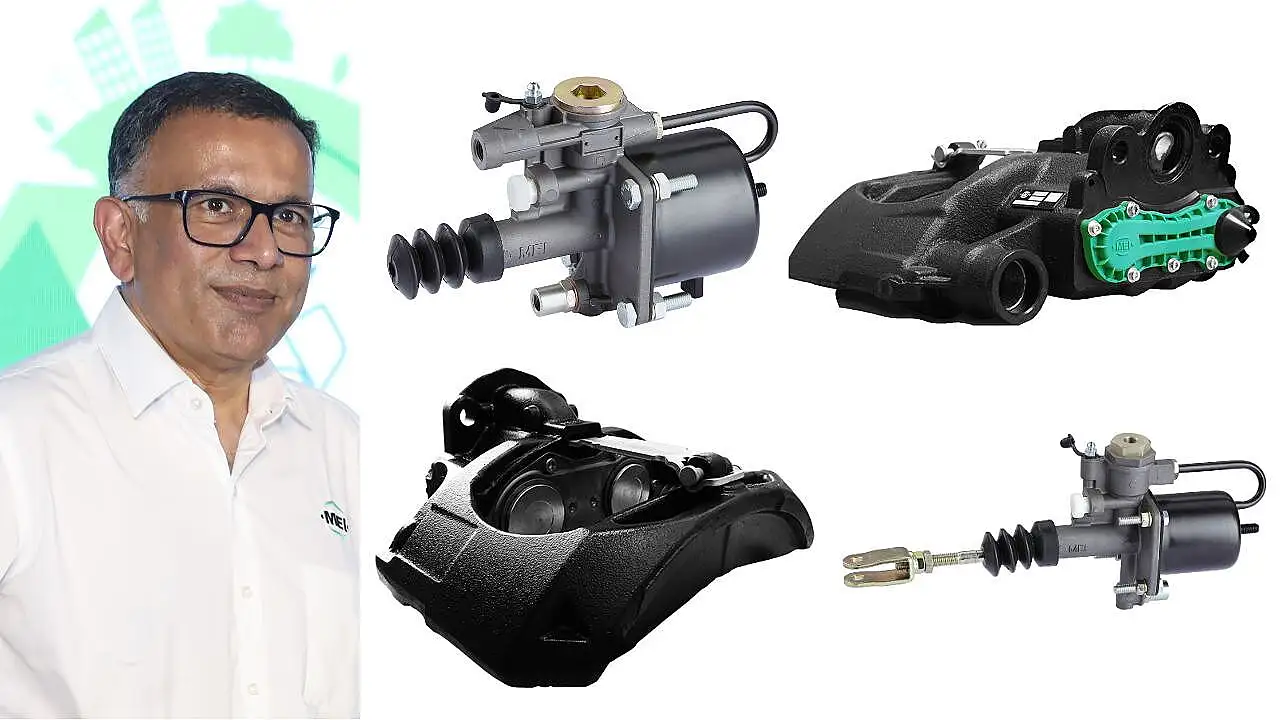

Speaking to Mobility Outlook, Sriram Sivaram, Joint Managing Director, MEI, acknowledged the opportunities for expanding their business. 'Our core focus remains on being a truck brake company rather than a foundry,' he explained. The foundry was originally established as part of a vertical integration strategy, born out of necessity when capable suppliers couldn’t be found. Today, 40% to 50% of the foundry’s capacity is dedicated to supporting its own operations, ensuring the quality and reliability of the components it makes. This strategic move not only secures the supply chain but also positions MEI to meet increasing demand with confidence.

When asked about expanding capacity to meet anticipated business growth, Sivaram offered a candid response: 'We are currently uncertain about our next steps. As a medium-sized company, we approach investments and growth with caution. Over the past 20 years, we have achieved a steady 15% CAGR, which we view as a sustainable rate of organic growth. Maintaining a strong financial position with a debt-free balance sheet is a priority for us, and this stability guides our growth strategy.'

He further elaborated on the strategic dilemma: 'The challenge we face is deciding where to focus our expansion—whether to become a larger foundry supplier or to bolster our brake business. Our strategic intent is clear: we want to enhance our brake business, but achieving this requires expanding our foundry capacity. Our in-house foundry has proven instrumental in supporting our growth and enhancing our capabilities. While we continue to source some castings externally, our integrated approach has been beneficial.'

Sivaram highlighted the potential for growth within their brake business. 'We are already the largest manufacturer of slack adjusters and a few years ago have ventured into air disc brakes, a product line with significant market potential. In Europe, disc brakes account for about 75% of the market, while in the US, it is around 40% and rising. Although we started in the aftermarket, we are now securing OE business. If this trend continues, we anticipate substantial growth, aiming to triple our current turnover of approximately $100 million (INR 800 crore) by 2030-32,' he mentioned.

Key Focus Area

The company’s immediate priority is to secure green certification for all its units and products, a goal “we expect to achieve within the next twelve months. This step is not particularly challenging, as our most complex operation—the foundry—has already been certified.” The remaining processes, primarily machining and assembly, have a comparatively smaller carbon footprint, especially since the company has been utilising renewable energy across all of its plants.

The most significant non-green component is the use of diesel backup generators during grid failures, a challenge it currently faces. However, emerging technologies offer promising solutions, which is why “we aim to reach 100% carbon neutrality by 2030, despite the inherent risks.” Fortunately, achieving green certification doesn’t require complete carbon neutrality, allowing the company to move forward with this certification immediately.

Manpower Challenges

Workforce challenges in developed nations have given MEI a competitive edge in the global market. Sivaram explained that while foundries in developed markets are grappling with a severe shortage of skilled labour, MEI has been able to thrive. 'In these markets, the foundry business struggles primarily due to the lack of available workforce,' he noted. 'However, when it comes to other factors such as capital investment, power, and material costs, there isn't much difference globally,' he said.

The foundry industry has long been stigmatised as dirty, difficult, and dangerous, but at MEI, “we’ve challenged this perception head-on. Yes, foundries can be difficult,' Sivaram acknowledged, 'but they shouldn’t be dangerous or dirty.' When MEI built its plant, it made an intentional choice to coat the floors in white epoxy paint—a symbol of its conviction to cleanliness and safety. 'We don’t want to see dust or sand on the floor because if it’s there, it’s also in the lungs of our people, shortening their lives. That’s a responsibility we refuse to bear,' Sivaram emphasised.

This deep-rooted focus on health and safety has not only created a better working environment but also positioned MEI as a preferred supplier in the global market. Today, approximately 90% of its foundry’s capacity, beyond what it uses internally, is dedicated to exports.

Despite slightly higher shipping costs due to its location, MEI compensates by offering reliable, high-quality supply rather than simply competing on price. 'We didn’t win our business by being the cheapest,' Sivaram explained. 'We had to be competitive, yes, but more importantly, we had to be better—providing the consistency and quality that our international customers demand.' This strategic focus has allowed MEI to meet high standards of the developed world, securing its place as a reliable global supplier.

When the global President & CEO of Volvo Group Martin Lundstedt stated that 'sustainability should be profitable, and profitability should be sustainable,' it might seem like these concepts are at odds. However, I don't see them as being poles apart at all,” Sivaram said.

Reflecting on the Indian manufacturing landscape, he said there was a time when many component makers believed that producing high-quality products would inherently be more expensive. This mindset persisted until companies like Suzuki and Hero Honda revolutionised the industry by demonstrating that higher quality—achieved through better process capabilities, the right level of automation, and thorough training—actually leads to lower costs and higher efficiency.

“This is a lesson we learned by doing it ourselves, guided by the Japanese emphasis on quality. Today, our manufacturing systems are on par with the best in the world. Applying the same principle to sustainability, the question arises: does becoming a sustainable supplier mean you have to be more expensive? My discussions with Volvo revolve around this very point. We must remain competitive; we can't simply rely on being green and expect our customers to pay more,” he noted.

It's undoubtedly a significant challenge, but MEI has successfully navigated it. Achieving such a balance is possible, but it requires time and careful consideration to identify the right areas for improvement. The key lies in making strategic trade-offs—investing upfront in certain areas while understanding that these investments will lead to reduced operating costs and sustained profitability in the long run, he mentioned.

“If you approach it with this mindset—willing to invest capital now with the confidence that it will support long-term profitability—then the vision outlined by the Volvo Group CEO is entirely attainable. I fully agree with his perspective and believe it aligns perfectly with our approach at MEI. We’ve proven that sustainability and profitability can go hand in hand when executed thoughtfully and strategically,” Sivaram concluded.

Also Read:

Madras Engg Industries Meets Developed World’s Demands: Sriram Sivaram