Vivek Vikram Singh, MD and Group CEO, Sona Comstar, believes that the future of vehicles will be based on four key themes: electrification, intelligence, personalisation, and connectedness.

“Connected technology is something where we are lagging but thinking in that direction as well,” he told Mobility Outlook during a visit to the recent plant inaugural at Chakan near Pune.

According to Singh, Sona has begun to focus on electrification with its range of motors. It kicked off its journey back in 2016 with the e-axle. “This was the time when many OEMs were just thinking about it and we were already in the game,” he said.

His colleague, Kiran Deshmukh, Group Chief Technology Officer, added that the plan now is to optimise the business. The ‘switch reluctance’ motor, being developed jointly with the Canadian startup, Enedym, is the first step in this direction.

Looking Beyond China

Deshmukh said the idea is to reduce the dependency on China for motors given that most of them use magnets sourced from the country. Magnets constitute about 30-40% of the BoM (bill of material) in a motor, he said.

The target is to commercialise the switch reluctance motor next year. It can cater to the needs of any vehicle type — be it three or four-wheelers — while ranging from 10kW to 100 kW. Sona is also working with the IRP Nexus group and other players for more magnet-less motor technologies.

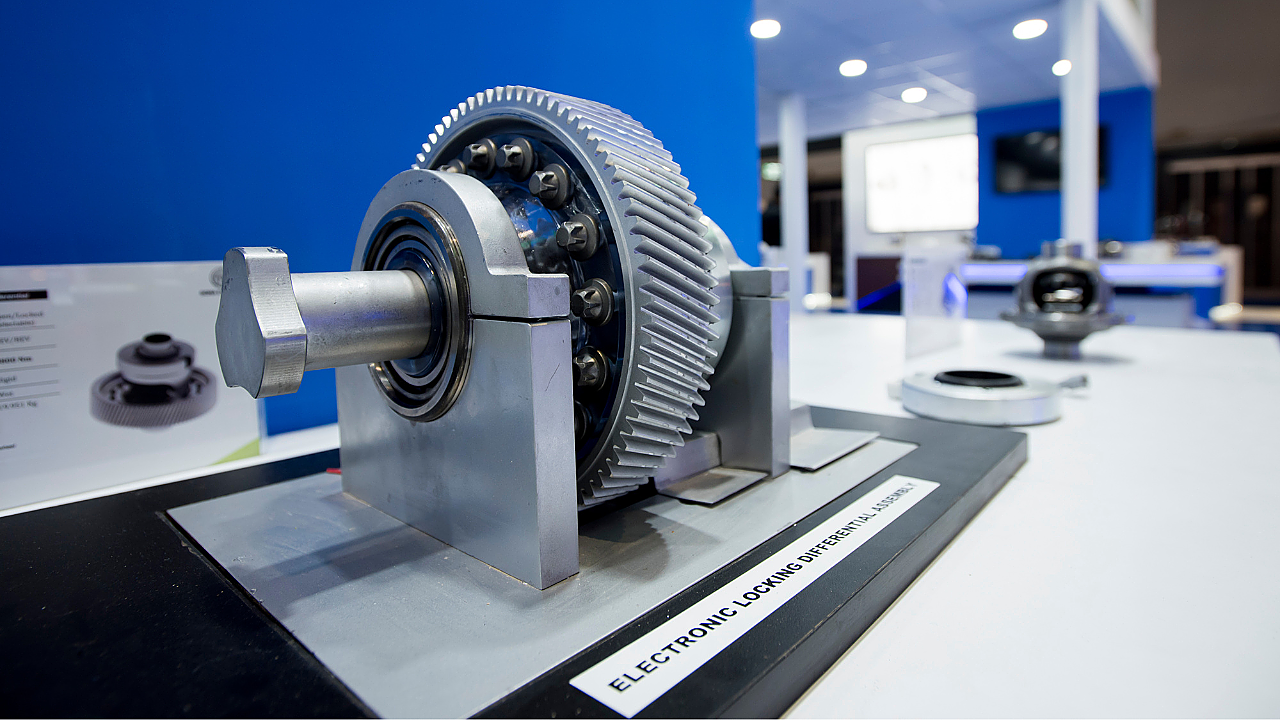

Meanwhile, the journey towards ‘intelligence’ has also kicked off with an electronic locking differential which will debut with a North American SUV next year. With the signal from the OEM's controller, the differential can be locked/unlocked in real time, in a fraction of a second. A solenoid coil inside the system creates the magnetic force and triggers the locking of one of the differential gears.

Helping Personalisation

Sona Comstar recently acquired 54% stake in the Serbia-based Novelic which caters to mmWave radar sensors, perception solutions and full-stack embedded systems. In the process, the company has a third business vertical in ADAS Sensors and Software to meet the needs of vehicle autonomy and automation.

While the sensor technology caters to the connected part to an extent, Singh said it would help the cause of personalisation in future mobility. “The technology can actually detect your heartbeat and based on that can limit the vehicle speed if the sensor detects something unusual,” he explained.

The personalisation effort is also managed with an integrated motor control module placed in the suspension of the vehicle. Singh said the system is designed to detect bumps/speed breakers and then respond to all external disturbances independently. Simply put, the motor creates a precise opposing force that counters the effects of uneven surfaces and allows the vehicle to cruise on all types of roads.

“If a driver wants to mimic a high speed driving situation without going at high speeds, the system will adapt the suspension system to a stiffer setting in order to mimic the high speed run. Hence, the suspension can be personalised as per the driver’s need at any given time,” explained Singh.

The system is still undergoing testing and validation with the company expected to commercialise the technology by FY25 with ‘S’ and ‘E’ type passenger vehicles.

On The Fast Track

Things have moved on quite rapidly since July 1, 2015, when Dr Surinder Kapur, the founder and then chairman, passed away and his son, Sunjay, took over. At that point in time, it only had the differential gear to offer from one plant in Gurugram. Today, Sona Comstar has 10 products, two business verticals and a slew of new projects in the pipeline. The number of plants has also grown to nine of which six are in India.

“Our greatest skill is the openness to change. Resilience is a core business model that is profitable and conservative,” said Singh. The ninth plant in Chakan replaced the one at Bhosari nearby and is 10 times as large. It is the second biggest in terms of volumes for the company.

This 10-acre facility takes care of the driveline business and can produce 11.8 million differential gears, with the target being 20.1 million by the end of FY25. Gurugram remains Sona’s largest plant with an annual capacity of over 40 million.

Chakan will play a key role in scaling up capacities and satiating the order book of INR 23,800 crore. “We were producing in the north and supplying everywhere. This facility should be able to cater to both the western region as well as exports,” Singh added.

Total volumes for the driveline business last fiscal was 51 million units with estimated revenues of over INR 2600 crore. Sona has been growing at 30-35% and this is where Chakan will play a role in taking the story forward.

The plant has installed 1mW of solar capacity which caters to 8% of the energy needs. The older Bhosari unit plant had an annual capacity of six million units and could be used as an R&D centre.

Also Read

Sona Comstar Aligns Strategies In Sync With Global Trend On EVs