In the ever-evolving landscape of automotive manufacturing, innovation remains the cornerstone of industry advancement. Leading this charge is Skillveri VR Simulators, a company leveraging cutting-edge automation and predictive AI technologies to revolutionise critical processes such as welding and spray painting followed by sealant application, going forward, and many such things. By blending human expertise with robotics, Skillveri is fundamentally transforming the manufacturing landscape, pushing the boundaries of efficiency, precision, and skill development.

Having made significant strides in welding solutions, the company's journey into the automotive sector was a natural progression. It wasn't long before their expertise in welding sparked customer interest in other areas, leading to collaborations with leading paint companies such as Berger, Asian Paints, Axalta and AxoNobel for applications ranging from protective to decorative and automotive repair coatings.

While automation has made its mark in many areas, the company identified an opportunity in making human labour more competitive with robots in terms of output quality and efficiency. Even though robots are employed for critical tasks like windshield sealant application, certain manual processes still require human involvement—particularly in lower-volume sectors like commercial vehicles. Here, human intelligence remains indispensable, especially when working on complex and non-standardised tasks. Talking to Mobility Outlook, the company’s CEO Sabari Nair, said, the company's goal is to ensure human performance matches robotic precision, elevating the value of skilled labour in the process.

Deploying Predictive AI

Another game-changing innovation lies in the realm of predictive AI, which aims to reduce production disruptions that are expensive. Currently, car manufacturers must halt existing production lines to test-manufacture new models, which incurs substantial cost and time. By applying predictive AI and ML, the company is working on systems that can foresee potential defects in new vehicle designs before they enter full production. Using data from existing training and production processes, the AI predicts flaws that might emerge in the new model’s production, allowing manufacturers to pre-emptively address issues. This technology could potentially save manufacturers millions of dollars and months of work, demonstrating a 100x return on investment, he said. “It's in very early stages; we have to see how productive it becomes. But we are sure that by paying a few lakh of rupees, they can save a few crore,” he explained.

The integration of virtual reality (VR) and extended reality (XR) with AI takes these capabilities a step further. Workers can be trained on new production lines using simulated environments before those lines go live, significantly reducing the time it takes to ramp up production. The company has been piloting this technology with selected industry players, promising to revolutionise the way automotive plants implement new designs and models, he said.

This kind of innovation isn't confined to automotive. The potential for predictive AI and immersive training extends across various industries including construction equipment, specialised equipment manufacturing etc, offering immense value for these niche sectors, he stated.

The Genesis

The journey of Skillveri has been shaped by the early experiences of its Founder and Co-founder, who laid the groundwork for its future success. Nair’s transition from software development to product marketing played a crucial role in shaping a unique approach to business. In his early days working at Vortex, a company focused on creating rural ATMs for underserved populations, he encountered invaluable lessons that would later inform his approach to building innovative solutions.

Starting in India in 2013, the company focused on developing and marketing its training simulators for various applications. However, it was in 2019 that its growth trajectory shifted when it made inroads into North America. “A North American client discovered us, leading to our first export of a unit to the region. Despite the subsequent challenges posed by the pandemic, we saw an opportunity: schools in North America needed practical training solutions for students learning remotely due to the widespread shift to Zoom-based education. In response, we quickly adapted our product to run on off-the-shelf hardware, particularly wireless headsets, which had just entered the market. This transformation allowed students to practice skills such as welding and spray painting from their homes, with their progress monitored centrally by instructors,” he mentioned.

However, the Indian market presented different challenges, with longer adaptation cycles and resistance to investing in new training methods. Many institutions questioned the need for training, citing concerns about employee retention and cost. However, “we knew that the long-term costs of neglecting training far outweighed the initial investment. Thus, we offered our solutions as a comprehensive package, covering warranty, system integration, and support,” he pointed out.

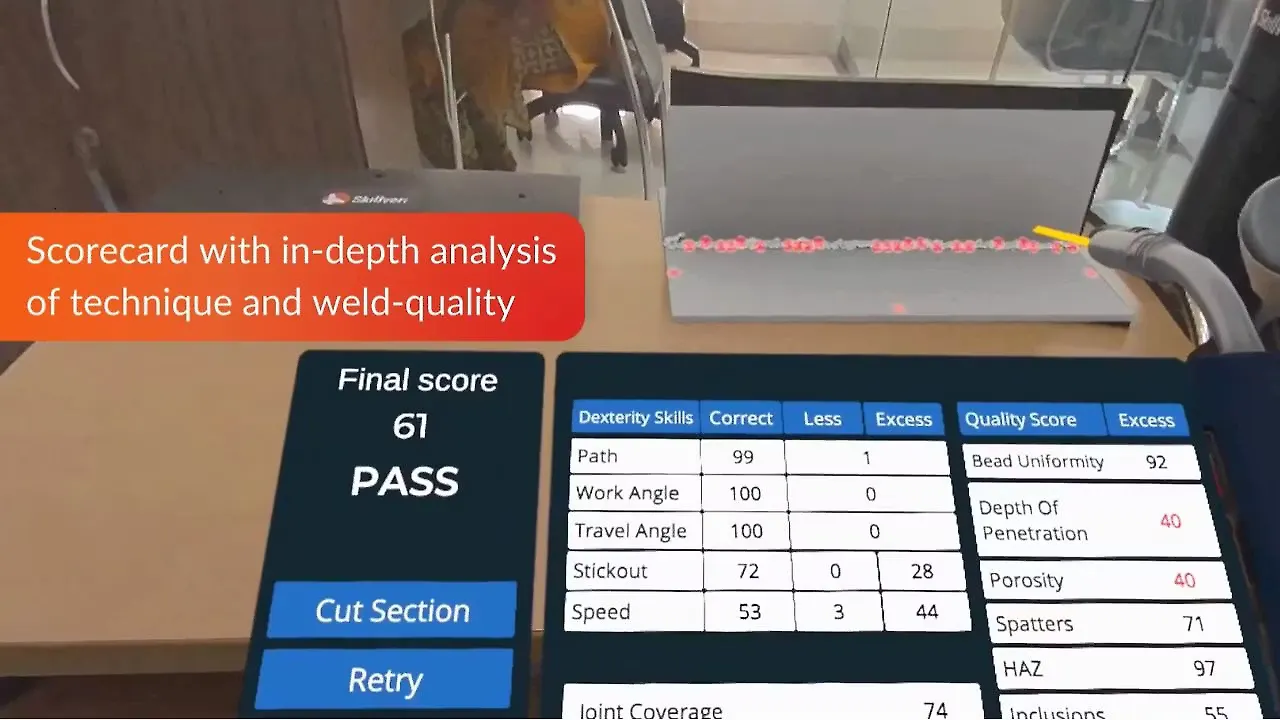

These virtual reality and AI-powered tools help trainees master skills like welding and painting more effectively. Skillveri’s products offer a highly immersive experience, seamlessly blending virtual workpieces with real surroundings through advanced Mixed Reality technology. The simulation covers four types of welding, each with its own machine, torch, and settings, allowing users to select metal type, joint type, thickness, and gas. Real-time on-screen feedback guides users during welding, with detailed performance scorecards generated at the end. They can also virtually cut and analyse welded pieces for imperfections.

The VR mode simulates various industrial environments, such as construction sites, oil & gas plants, and shipyards, enhancing the realism of welding practice. Similarly, the spray-painting simulator caters to automotive, protective, and decorative segments, offering live feedback, performance scorecards, and detailed analysis through thickness maps and hand movement tracking. It also calculates coat efficiency and potential monetary losses due to inefficiency or wastage. Skillveri simulators can be paired with real industry-grade welding and painting tools to provide an authentic hands-on learning experience.

Cost Optimization & Productivity Boost

The company’s simulator could reduce training time by 50% and material wastage by up to 80%. This is not just about cost savings; it’s about enabling quicker entry into the workforce, especially for those who might otherwise struggle to afford long-term training programmes, he said.

To date, the company sold around 600 units globally, with approximately 400 in the US and the rest in India. These simulators, manufactured at its facility in Chennai, have reached three million users across these units, offering training for a wide range of applications, including welding, spray painting, HVAC, and solar panel installation.

In the US, its primary customers are institutions, while in India, private training institutions make up most of its client base. However, “we expect that in the next five years, public technical institutions in India will account for 80% of our domestic sales,” he said. Currently, the automotive sector constitutes about 35% of its sales in India and 40% in the US. The US market has become a significant driver of growth for the company, with sales in the region surpassing their Indian sales within just 18 months.

Women In Shopfloor

A pivotal moment in the company’s journey occurred at a Pune training centre, where GE introduced a policy that 50% of its new factory workforce would be women, marking their entry into the welding field. Using welding simulators with unbiased scoring, seven of the top ten welders turned out to be women. Inspired by this success, GE continued hiring female welders, with similar outcomes at other companies including Ashok Leyland at its Pantnagar plant.

Another notable instance took place in Kochi during a pilot project with Berger Paints. A member of the Kudumbashree - women’s self-help group, skilled in traditional painting, decided to try an advanced airless spray-painting machine. Starting with a score of 67, she improved to 98 after a few hours of practice, demonstrating remarkable precision. This technology empowered her to excel in a real-world session the next day, boosting productivity by four to five times.

Nair firmly asserts that the company's guiding principle is to view technology as a means to address real-world challenges, rather than an end in itself. The emphasis is on ensuring that the product delivers measurable value to the end user—be it a rural villager or a factory trainee, he signed off.

Also Read: