The landscape of internal combustion engine (ICE) vehicles is undergoing a rapid transformation, with core technologies across all segments evolving at an unprecedented pace. This swift progress is not only accelerating obsolescence but also driving a wave of new developments, even in hardware.

At the heart of this revolution lies the fusion of automotive engineering and digital technology, giving rise to a new paradigm where software is the key determinant of a vehicle's capabilities, performance, and user experience. This shift has positioned Tier-2 and Tier-3 companies in the software domain as direct suppliers to OEMs, challenging the traditional dominance of Tier-1 suppliers.

In a conversation with Mobility Outlook, Gilles Mabire, CTO, Continental Ag, said that the software market is poised for explosive growth, attracting numerous players eager to enter the field. While Continental acknowledges the need to collaborate within the ecosystem to navigate this complexity, it proudly stands as a pioneer, being the first to introduce High-Performance Computers (HPCs) to the market.

Establishing partnerships with multiple suppliers was a complex journey, requiring significant time and effort before “we could secure the right collaborations.” A crucial aspect of this process is bridging the gap between software functionalities and safety-critical elements within the vehicle. As custodians of passenger safety, Mabire believes that the company bear a profound responsibility to ensure that every feature and technology introduced to the market is rigorously tested and safety-proof.

Continental has meticulously defined and adhered to stringent safety protocols, leveraging its extensive experience and deep-rooted expertise. This ensures that its software solutions not only enhance vehicle performance but also safeguard lives. It's a level of assurance that is challenging for newcomers to achieve without the foundational knowledge and experience that we possess, he pointed out.

Advantages Of HPCs For OEMs, Tier-1 Suppliers, End Customers

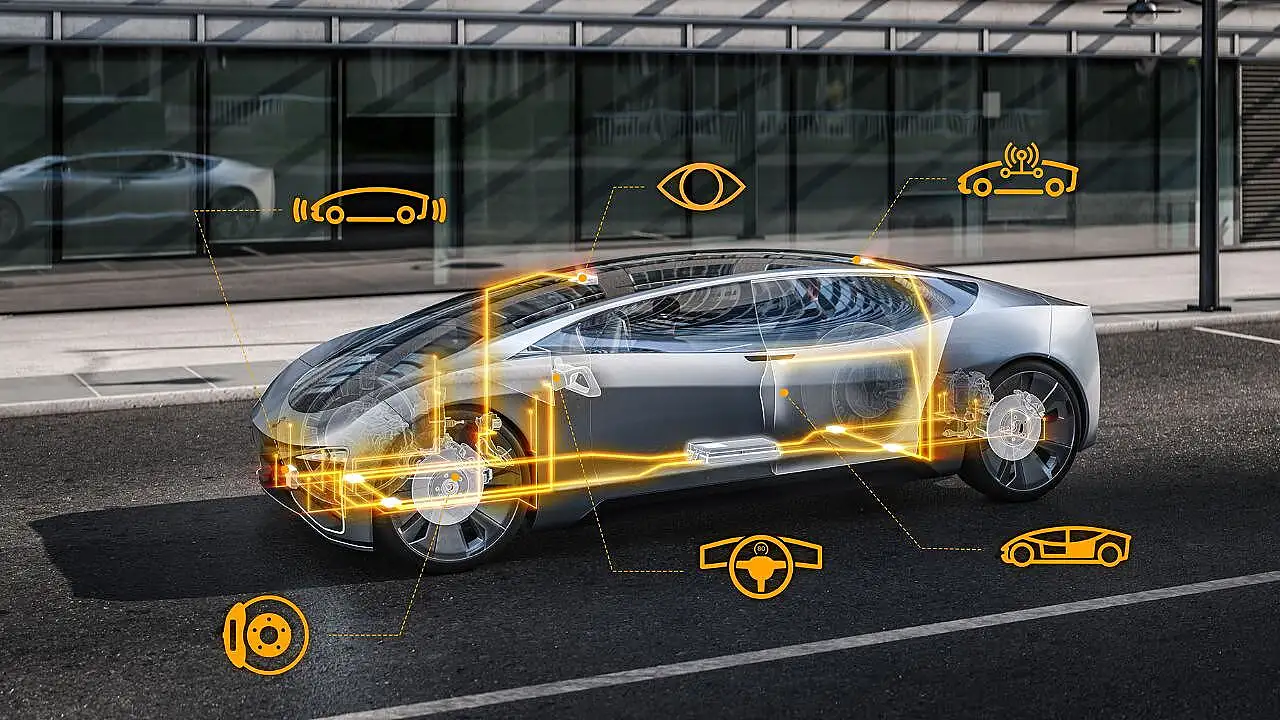

Mabire, who is also the Head of Software and Central Technology at Continental, asserted that HPCs play a pivotal role in simplifying vehicle architecture by significantly reducing the complexity and volume of wiring harnesses. This reduction not only minimises the metal content and connectors within the vehicle but also paves the way for a more streamlined and efficient design. HPCs enable the creation of a versatile architecture that seamlessly integrates sensors for a multitude of applications.

Currently, vehicles are burdened with isolated, siloed functions that are incrementally added, making upgrades a challenging and cumbersome process. However, by decoupling software from hardware, HPCs facilitate rapid and continuous development, allowing for the seamless implementation of new functions and software updates throughout the vehicle's lifespan.

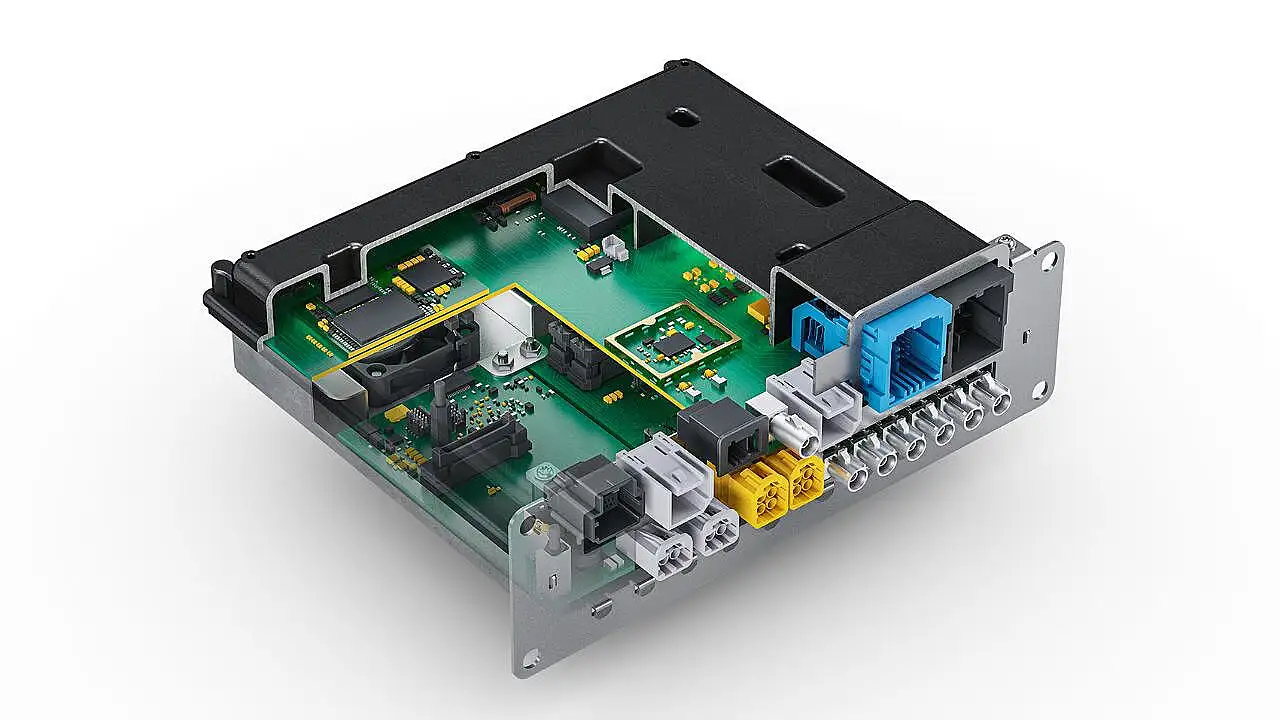

Continental recognises the transformative potential of HPCs and is focussed to advance beyond the traditional Electronic Control Unit (ECU) systems that have long dominated automotive design. The objective is to ensure that 75% of all HPCs serve as cross-domain tools, functioning more like servers than isolated control units.

Today's vehicles increasingly “resemble moving data centre,” a reflection of the ongoing transformation within their electrical and electronic (E/E) architectures. Rather than relying on a convoluted network of numerous ECUs and microcontrollers, modern vehicles are transitioning to a powerful server-based architecture that supports all electronic functions.

“Previously, almost every single function or functional area was integrated into the network with a dedicated ECU. This has led to a very heterogeneous and complex architecture of embedded systems, which was no longer suitable for further innovations such as the connection of the car into the Internet of Things (IoT),” he said.

Continental’s HPC approach is strategically divided into four distinct application areas: the Cockpit HPC, which engages directly with the driver; the Body HPC, responsible for regulating data streams within the vehicle and acting as an intelligent interface to the internet, cybersecurity, and communication; the automated driving (AD) HPC - tailored for autonomous driving functions; and the Safety HPC, dedicated to ensuring vehicle safety.

A key driver behind the evolution of the electrical/electronic (E/E) architecture from a network of multiple ECUs to a streamlined HPC server infrastructure is the introduction of a new intermediate layer—Zone Control Units (ZCUs). ZCUs play a critical role in “cleaning up” existing E/E architectures by reducing the number of ECUs and minimising the weight of wiring harnesses.

As central computing power becomes increasingly concentrated in a few HPCs, the importance of ZCUs grows, he said. These controllers ensure the reliable execution of vehicle functions by serving as intermediaries between high-performance computers and the vehicle's sensors and actuators. Each ZCU integrates functions across various domains within a specific zone, acting as a hub for both power distribution and data connectivity requirements for all connected devices, he added.

“With the help of HPCs, upgradation of the vehicle becomes very easy. It looks like an IT infrastructure moulded into the environment of a car. But with our experience on how to develop and produce them across regions and scales, makes it a little less complicated. It further gives an opportunity to the OEMs to differentiate themselves from each other by offering high, complex features to their end customers, allowing the end users to enjoy the new and latest functions in the car,” Mabire noted.

These days, various American EV companies offer add on functions, new features and software upgrade on a weekly or a monthly basis. Therefore, the same cannot be executed in vehicles with the traditional vehicle architecture, thus implying the importance of the new and upgraded vehicle architecture, stressed Mabire.

The next frontier in data processing is on the horizon with the advent of quantum computing, poised to revolutionize the industry. The question now is when Continental will integrate this groundbreaking technology into the development of systems and modules for automotive applications. In response, Mabire stated, “Right now we do not have an example of quantum computing based application, because it is too early. I think it will start from the IT environment to use the quantum processing power on the cloud or back end to offer better functions.”

However, the prospect of integrating real-time quantum solutions directly into vehicles in the near future seems unlikely, particularly when considering the cost-effectiveness of such implementations.

Continental’s exploration of quantum computing also extends to cybersecurity, as the technology holds the potential for both innovation and threat. Quantum computing can be used to develop advanced algorithms and protective measures to safeguard vehicles from potential cyberattacks. “We are proactively building our systems to be resilient against future threats, including those posed by quantum computing,” he added.

While quantum-driven hardware solutions are on the horizon, realistically, he does not foresee the emergence of embedded quantum computing-based HPCs within vehicles for at least the next five to eight years.

Digitalisation

Digitalisation is transforming not only the products developed by automotive suppliers and OEMs but also the very processes by which parts and vehicles are manufactured. This technological shift offers supplier companies a multitude of opportunities, from enhancing efficiency and productivity to effectively mitigating cost-related challenges driven by various factors. Sharing Continental’s experience, Mabire said, “We see AI as a way to empower our company and our products. At Continental, we aim to use AI and digitalisation as much as possible throughout the development process. With the use of AI and digitalization, we see a huge opportunity to optimize and gain in productivity.”

The company leverages Generative AI in conjunction with synthetic data to refine and mature its algorithms for Advanced Driver Assistance Systems (ADAS) functions. Additionally, AI and Machine Learning are employed to train and fine-tune specific features within the vehicle, such as anti-pinch mechanisms and automatic trunk openers, which traditionally incur significant costs. However, while these advancements are substantial, they alone are not sufficient to meet the evolving demands of modern automotive technology.

“We also are looking at development and processes which are somehow function driven. Additionally, we are looking at how to implement a co-pilot AI based solution to ease the life of our people on the daily basis with the goal that we need to further accelerate focus on what is important for us,” Mabire signed off.

Also Read:

Continental Thrives On India's Skilled Workforce, Market Importance