As the automotive industry undergoes a seismic shift towards digitalization and electrification, Mercedes-Benz Berlin-Marienfelde is emerging as a global hub of innovation, redefining manufacturing efficiency, sustainability, and technological integration.

From Artificial Intelligence (AI)-powered smart assistants to humanoid robots and next-generation axial-flux motors, the historic Berlin-Marienfelde plant is spearheading the transformation of Mercedes-Benz’s global production network.

A Digital Factory at The Forefront Of Industry 4.0 And Beyond

Established in 2022, the Mercedes-Benz Digital Factory Campus (MBDFC) in Berlin-Marienfelde has become the global competence centre for digital production technologies. At its core is MO360, the company’s state-of-the-art digital production ecosystem, which integrates real-time data, AI-powered automation, and next-generation robotics into automotive manufacturing.

Today, Marienfelde is more than just a production facility—it is a testing ground for cutting-edge technologies before they are rolled out across Mercedes-Benz’s global assembly plants. The facility played a pivotal role in preparing the Rastatt plant for the launch of the new Mercedes-Benz CLA, the first model to incorporate the advanced Mercedes-Benz Operating System (MB.OS).

AI, Robotics: Redefining Future Of Manufacturing

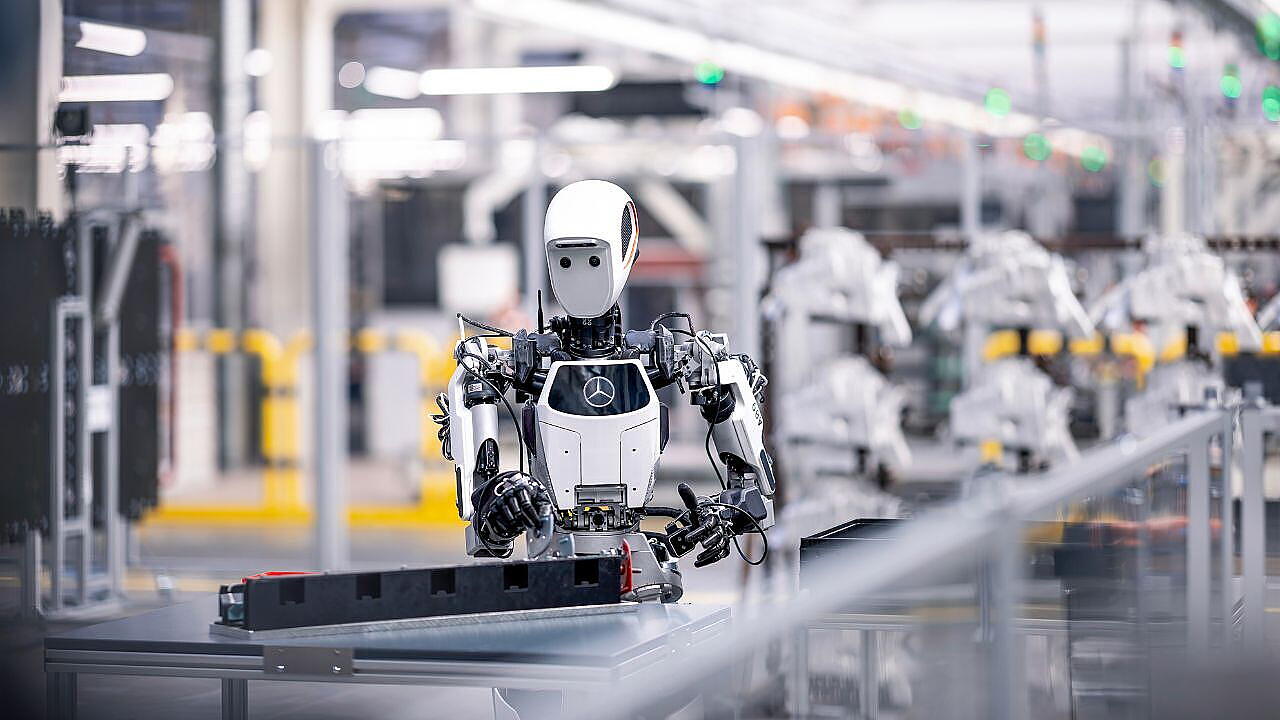

One of the most groundbreaking advancements at Marienfelde is the introduction of humanoid robots from US-based Apptronik, marking a new era of AI-driven automation in automotive production.

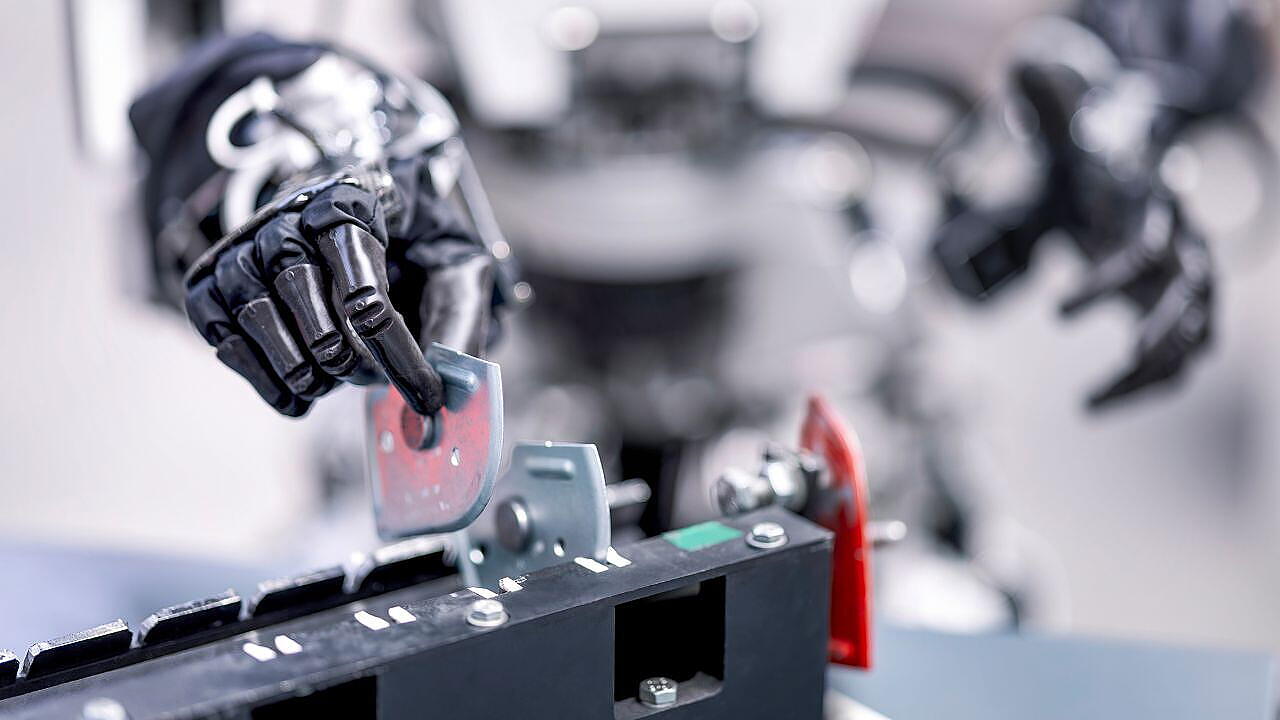

Mercedes-Benz has been using industrial robotics since the 1970s, but the integration of humanoid robots represents a significant leap forward. Apollo, one of the world’s most advanced humanoid robots, is being trained to perform repetitive and physically demanding tasks such as:

- Transporting components and modules to the production line

- Carrying out initial quality checks

- Assisting highly skilled production staff with assembly

To refine Apollo’s capabilities, Mercedes-Benz employees are transferring real-world manufacturing expertise through teleoperation and augmented reality training. The ultimate goal? Autonomous robotic operations—a technological milestone that redefines efficiency, flexibility, and precision in automotive manufacturing.

AI-Powered Smart Assistants

Beyond robotics, Artificial Intelligence is reshaping manufacturing at MBDFC. The MO360 AI Factory is making AI tools accessible and intuitive, providing real-time insights, predictive analytics, and automated problem-solving.

Mercedes-Benz’s Digital Factory Chatbot Ecosystem allows employees to instantly access production databases, ask questions about machine maintenance or best-practice methods, and receive instant, multilingual AI-generated responses.

Katrin Lehmann, Chief Information Officer of Mercedes-Benz Group AG, “AI takes over tasks we enjoy less, giving us more time to focus on creativity and value-adding innovation. When applied strategically, AI becomes a key driver of business success.”

Another powerful AI tool is the virtual multi-agent system, which quickly identifies and resolves quality deviations in production. Instead of manually troubleshooting issues, engineers rely on AI agents that analyze vast amounts of data, detect anomalies, and suggest solutions at the touch of a button.

Axial-Flux Motor Technology

As the automotive industry transitions toward electrification, Berlin-Marienfelde is playing a crucial role in shaping Mercedes-Benz’s all-electric future. Beginning next year, the site will manufacture high-performance axial-flux electric motors, solidifying Berlin’s status as a centre of excellence for high-tech EV powertrains.

What makes axial-flux motors revolutionary? Unlike traditional radial-flux motors, these compact, lightweight power units deliver superior efficiency and torque density, making them ideal for next-generation electric vehicles.

Manufacturing an axial-flux motor involves around 100 production steps, with 65 processes new to Mercedes-Benz and 35 entirely new to the industry. Cutting-edge innovations—including advanced laser technologies, AI-assisted assembly, and novel bonding techniques—have resulted in over 30 new patent filings, reinforcing Marienfelde’s leadership in automotive process innovation.

A Vision For The Future

From AI-powered digital production and humanoid robotics to next-gen electric powertrains, Mercedes-Benz Berlin-Marienfelde is shaping the future of automotive manufacturing. By seamlessly merging human expertise with cutting-edge technology, the historic Berlin plant is proving that the factory of the future is already here.

Also Read:

Mercedes-Benz Pioneers Special Marker Lights For Automated Driving In Germany