With a legacy of over five decades rooted in sustainability and innovation, ebm-papst, the global leader in ventilation and heating technology, is accelerating its green transition through advanced digitalisation, energy efficiency, and deep localisation—especially in India, a market the company sees as vital to its future growth.

At the core of its mission is its focus on climate protection and carbon reduction, not as a recent initiative but as a fundamental principle embedded in its DNA. 'We’ve long believed that every new product must outperform its predecessor both economically and ecologically,' saidDr Klaus Geissdoerfer, CEO of the ebm-papst Group at a media briefing recently.

This philosophy is reflected in the company’s annual growth of nearly 4%, with a turnover of €2.4 billion, while consistently investing €10 million each year in sustainability measures like solar energy, energy-efficient buildings, and retrofitting of production sites, he pointed out.

The company’s vision of leading air technology into the next generation is being realised through its digital platform NEXAIRA, a cutting-edge ecosystem developed with strong support from the team in India. NEXAIRA, he said, empowers customers with smart features such as predictive maintenance, filter clogging alerts, and de-icing systems, which together can boost energy efficiency by 30–70%. 'With our software and fan technology, we’re not just selling a product—we’re offering integrated solutions that redefine energy savings,' Dr Geissdoerfer noted.

ebm-papst’s commitment to digital transformation is equally robust, having invested €17.5 million last year and earmarking another €30 million this year towards digitalisation and AI. This complements its strong focus on R&D, with €140.2 million, or over 5% of total revenue, dedicated to technological advancements.

Beyond technology, the company is deeply committed to achieving net-zero emissions under Scope 1 and 2, supported by renewable power purchase agreements, solar rooftop installations, and green energy sourcing across its global facilities.

India Expansion

With its footprint structured across the Americas, Europe, and Asia Pacific, ebm-papst is strategically expanding operations in India, having broken ground on 4 April 2025 on a 14.2-acre site in Sunkuvarchatram, located on the upcoming Chennai-Bangalore highway. With INR 340 crore investment in Phase 1, the plant will span 23,000 sqm and employ around 700 people (direct and indirect) when fully operational. The installed capacity will them increase by four folds from the current level, said Atul Tripathi, Managing Director of ebm-papst India.

Already ebm-papst India has been operating two manufacturing plants in Chennai, established in 1996 and 2010 respectively. A third facility, the Global Capability Centre (GCC), opened recently with 130 employees. It has four regional sales offices across India, with a total workforce of about 375 employees.

Local For Local

The Indian facility will serve as a cornerstone for the company’s 'local for local' strategy, enabling end-to-end processes from product development to manufacturing and delivery within the region. “It’s a natural step for us to build in India, not just to serve the local market, but to support supply chain resilience and regional sourcing,” Tripati said, adding that India’s growing supplier ecosystem offers additional job creation potential.

In India, ebm-papst is actively engaged in segments like air conditioning, air handling units, chillers, clean rooms, residential ventilation, data centres, and renewable energy systems. While heating applications are limited due to regional climatic conditions, the company is involved in select applications like heat pumps and natural gas boilers. The upcoming plant will support not just domestic demand, but also exports to APAC (excluding China) and the Middle East, he said.

Product Range

The range of products manufactured from ebm-papst in India are EC fans range including RadiPac, RadiCal, AxiBlade etc., covering diverse applications. The new plant will make RadiPac BG 150 motors, Tripati said.

Market Focus In India

The Indian arm has identified five key growth segments in the domestic market, each offering substantial long-term potential. Data centres remain a major driver, with the segment’s energy consumption expected to rise sharply from 340 TWh in 2022 to 857 TWh by 2028. In this energy-intensive environment, its EC fans play a critical role by reducing cooling-related energy consumption by up to 50%.

In the commercial building segment, the company supplies energy-efficient EC motors used in air handling units, chillers, and cooling towers, offering significant operational savings. In the renewable energy space, its high-performance fans support thermal management in solar inverters and wind energy systems, both of which are experiencing rapid expansion in India, in every industrial segment, including automotive.

The cleanroom and electronics manufacturing segment is another key focus area, driven by India’s push for domestic semiconductor production and the establishment of electronics facilities, including those by vehicle manufacturers and component suppliers.

Complementing these markets is the growing opportunity in retrofits, where outdated conventional fans in existing facilities are being replaced with advanced, energy-efficient alternatives from ebm-papst. The investments made towards EC Fans over the conventional fans can be amortised within 6 months if the units are working 24x7, Tripathi explained.

Thomas Nuernberger, CSO of the Group and CEO for Air Technology APAC & MEA, said, service is a strategic differentiator in Asia where customer experience expectations are high.

Business Growth & Ambitions

Tripathi said the Indian subsidiary grew from €27 million in FY23 to €48 million in FY25 and aims to reach €100 million by FY28, targeting a CAGR of 27%. The company is targeting 80% localisation over the next three to four years, up from the current 35–40%. Its supply chain already spans across India, with plans to further develop local suppliers. Key areas of focus for localisation include aluminium die-cast parts, sheet metal components, plastics, and printed circuit boards. At present, the company imports a significant portion of these from China and Germany. “Our aim is to reduce supplies from China,” Tripathi said.

Nuernberger added, “By localizing production and strengthening supply chains, we are ensuring that we can respond quickly and effectively to the needs of our Indian customers.”

According to Dr Geissdoerfer, the booming data centre market presents a particularly compelling opportunity. With global energy demand from data centres expected to reach 257 TWh by 2028, cooling remains a major concern. ebm-papst’s Next Aero Systems, combined with NEXAIRA’s digital intelligence, can reduce cooling energy consumption by up to 50%, translating into savings equivalent to the output of 20 power plants. The company is already in discussions with data centre operators for retrofitting and new installations, making a significant contribution to global energy conservation goals.

Crucially, the Indian team has been instrumental in driving this digital transformation. Their contribution to NEXAIRA’s development has been pivotal, with the platform set to expand further in coming years. 'India has always held great promise, and we are now seeing that potential become reality,' he said. “With such remarkable talent and momentum here, we are excited about what’s ahead,” he added.

As ebm-papst pushes boundaries in sustainability, localisation, and digital innovation, its investment in India not only aligns with its global strategy but also reflects a deep belief in the country’s role as a future-ready hub for clean and smart technologies.

Automotive

The company’s influence extends beyond data centres into automotive manufacturing infrastructure, where the demand for precise heating, cooling, and air cleaning systems is critical. The company supplies high-efficiency ventilation units for factory rooftops, building-wide climate control, and air management systems—essential components in modern, energy-conscious production facilities.

While the company scaled back its direct involvement in the passenger car segment due to the low utilisation time of its fans, it plays a crucial role in supporting refrigerated trucks, where cooling units operate for extended hours—making the use of highly efficient fan systems both practical and valuable. 'In such applications, long operational times create a clear cost-benefit case for our technology,' Dr Klaus Geissdoerfer explained. Additionally, ebm-papst provides solutions for railway applications, underscoring the versatility of its air and motion technologies across transport and logistics sectors. This approach reflects ebm-papst’s focus on directing its innovation where it has the greatest impact, maximising efficiency and sustainability for both customers and the environment.

Expanding Potential

Although ebm-papst India does not yet have a significant footprint in the Indian automotive sector, the landscape presents substantial growth opportunities. With the rapid expansion of electric mobility, the company is well-positioned to tap into emerging areas such as thermal management solutions for EV charging stations, particularly through advanced cooling systems for high-voltage cables. Additionally, there is strong potential in supplying cooling circuit controllers for the electronics manufacturing sector, as well as in ventilation and air-flow solutions for automotive paint booths—a space where the company’s global expertise in precision air technology can deliver high efficiency and energy savings.

A compelling example of ebm-papst’s potential in the automotive domain comes from its collaboration with Mercedes-Benz in Argentina. As featured in the company’s mag (Oct 2024 edition), the carmaker undertook a two-phase retrofit of its ageing paint booth ventilation system, replacing outdated AC fans with 69 RadiPac EC fans arranged in custom-sized FanGrids. This upgrade significantly improved air circulation—up to 658,500 m³/h across four booths—and will double in scale with a second phase in 2025. The retrofit delivered multiple benefits: precise climate control for optimal paint application, advanced real-time monitoring via ModBus interface, built-in redundancy for continuous operations, and a notable enhancement in production reliability and finish quality.

Future-ready Strategy

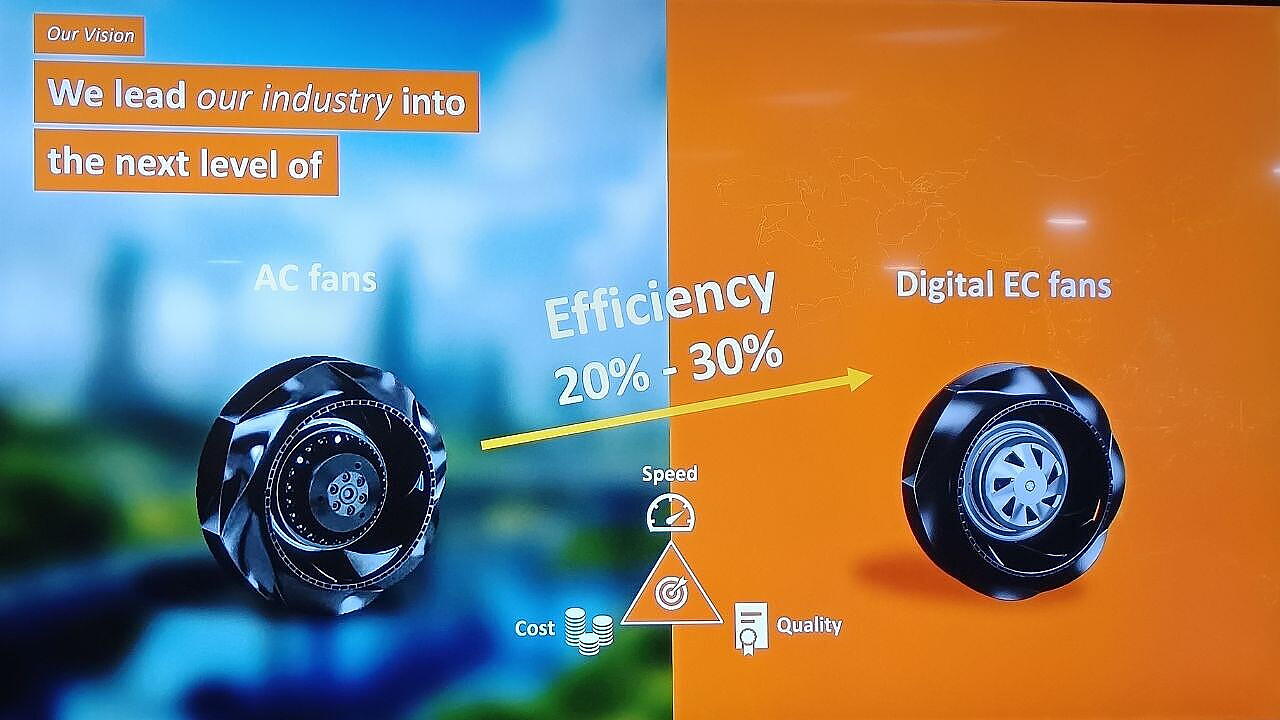

ebm-papst India’s future-ready strategy centres on advancing digitalisation and enhancing energy efficiency across its operations. Product innovation plays a pivotal role, with a focus on EC fans that integrate electronics and rotor motors to deliver compact, high-efficiency solutions. The company is also introducing Active Power Factor Correction (PFC) technology to manage grid harmonics effectively, particularly relevant for applications in data centres and commercial HVAC systems. Another notable development is fan grid optimisation, designed to reduce energy consumption by 20–30% in building ventilation systems.

Also Read:

ebm-papst Expands India Footprint With New €36 Mn Chennai Plant To Power APAC & MEA Growth