During a recent discussion with Mobility Outlook, Maxion Wheels' CEO, Pieter Klinkers, was spot on in highlighting the growing significance of the company's Indian arm within its global operations.

'The Indians are leveraging global knowledge, but the world is also beginning to look toward India,' he said. While Maxion Wheels’ aluminum wheel plant in India is only five years old, some of the company's other facilities have been operational for over four decades, he pointed out.

'Initially, the Indian team absorbed a great deal of expertise from our more established plants. But now, it's remarkable to see that other plants are starting to adopt ideas and innovations from the Indian facility. To achieve this level in just five years of production is impressive, and it’s now a level playing field,' Klinkers stated.

On the topic of digital transformation, he emphasised that India is leading the way. 'India is ahead of our global average in terms of digitisation. Of course, building a new plant allows you to implement the latest technologies from the start. But what's really driving this success is the Indian team's strong motivation for digital innovation, including advancements in Artificial Intelligence. In that respect, India is well ahead of many of our plants worldwide.'

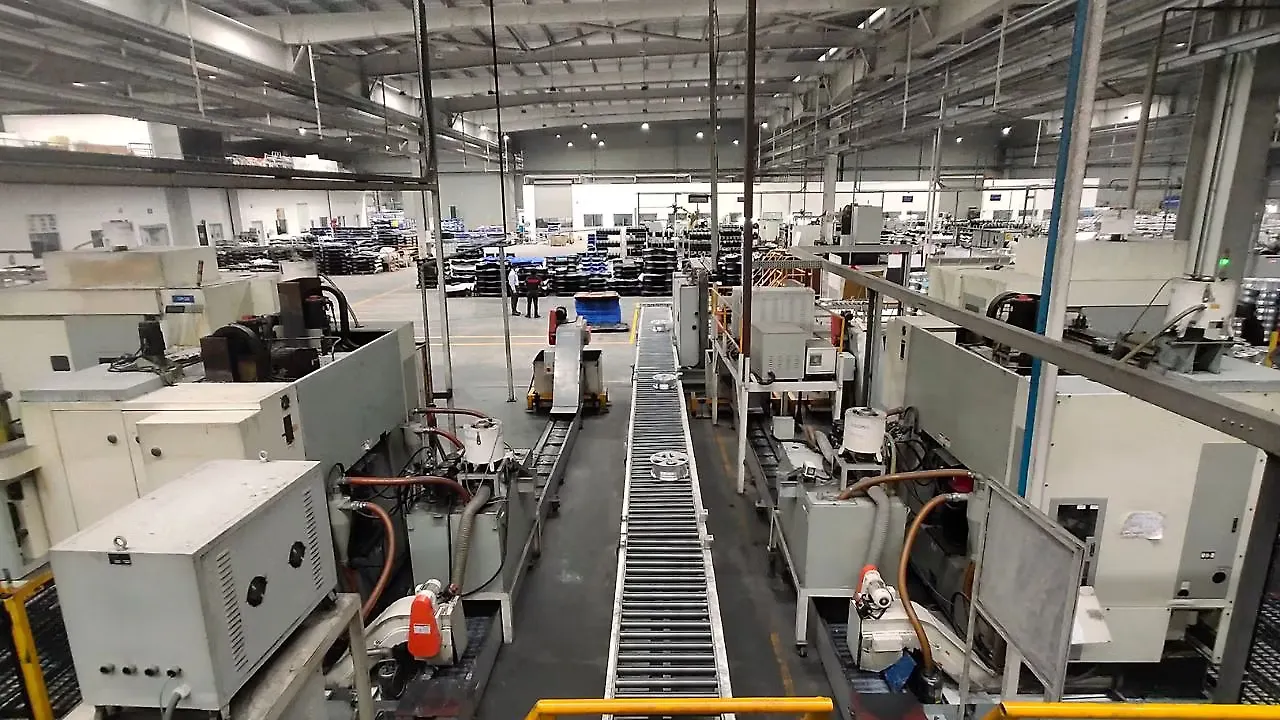

Sutheep Ratnabhas, President of Maxion Wheels’ Asia business unit, elaborates on the company's cutting-edge use of data and technology. “We conduct extensive advanced analytics on the vast amount of data we collect throughout our production processes,' he explained. 'The sheer volume of data is immense, and a significant focus is placed on harnessing AI to enhance these analytics. This allows us to optimise production formulas and unlock efficiencies that were previously unattainable. In many respects, our plant is operating at a near state-of-the-art level.'

Ratnabhas emphasises how the integration of big data into Maxion Wheels' operations is a key differentiator. 'We’re leveraging these insights to our advantage, driving improvements across our operations. Importantly, we’re also sharing this wealth of knowledge with our sister plants globally, ensuring that best practices from our Indian facility are being adopted worldwide.'

Focus On Local Market, With Export Potential

Klinkers reiterated that Maxion Wheels' primary focus remains on serving the local market, given the high costs associated with shipping wheels globally. Transporting wheels across the world is not an inexpensive endeavour, he noted. However, he acknowledged that export opportunities may arise, particularly in the steel wheels segment. 'While our strategy is predominantly centered around domestic demand, we remain open to the possibility of exporting steel wheels when the right opportunities present themselves.'

Wheels For EVs: Balancing Aerodynamics, Weight

Traditionally, thin-spoke wheel designs were created to optimise brake disc cooling, but on electric vehicles, these designs can cause unwanted drag, reducing efficiency. Modern EV wheel designs, however, prioritise large, smooth surfaces to enhance aerodynamics and improve airflow. This can sometimes raise concerns about potential heating issues due to reduced airflow. However, Klinkers offered a different perspective.

'Contrary to popular belief, heating is less of a concern with electric vehicles because regenerative braking dissipates much of the heat that traditional braking systems would otherwise generate,' he explained. The trend for EVs is moving towards more aerodynamic wheel designs, a shift that has been underway for several years and will likely continue, he said.

Addressing the question of weight, Klinkers acknowledged that eliminating spokes or adding solid surfaces can increase wheel weight. 'The lightest wheel is always the one with the thinnest and fewest spokes,' he said. 'When you start solidifying the wheel or adding covers, you're inevitably adding weight. OEMs are constantly seeking to reduce weight to improve range, but it's a delicate balance. Right now, range anxiety is such a priority for EV owners that efforts are focused heavily on aerodynamic efficiency, even if it means slightly more weight.'

Ratnabhas noted that customers are increasingly focused on aerodynamics, which has fuelled the debate around solid wheels and their aerodynamic benefits. 'The belief that solid wheels are the best solution for aerodynamics is something that will evolve over time,' he said. 'As battery technology improves and range increases, the emphasis on maximising every mile through aerodynamic enhancements, like covering wheels, will diminish in importance.'

He continued, 'It's only a matter of time before a breakthrough in battery range shifts priorities. When that happens, the need for these aerodynamic compromises will reduce, and we may see a pivot in design trends.'

Wheels for New Energy Vehicles

When asked about Maxion Wheels' readiness to support fuel cell vehicles, Ratnabhas explained that different customers have varying strategies based on regional priorities. 'Some of our key customers are fully committed to battery electric vehicles (BEVs) as the future, while others see hybrids or even internal combustion engines (ICE) as part of their long-term plans. There isn't a clear answer yet, and that's reflected in their diverse approaches,' he said.

The good news, according to him, is that wheel technology remains adaptable across all vehicle types. 'Regardless of whether it's an ICE, hybrid, or BEV, the fundamental role of wheels doesn't change significantly. Our focus is always on working closely with customers to find the optimal solution—whether it's designing fully covered wheels to boost aerodynamics or minimising weight through advanced design and optimisation.'

'Ultimately, it's about striking the right balance between weight, design, and performance. For BEVs, the emphasis may be more on reducing weight and improving aerodynamics, whereas for ICE vehicles, these factors might play a lesser role. But at the end of the day, it's all about optimising for the specific needs of each vehicle type.'

Exploring Synergies Beyond Wheels

While Maxion focuses on wheels, Iochpe, its parent company, specialises in other automotive components. When asked about potential opportunities to expand into adjacent areas to enhance both businesses, Klinkers highlighted the difference in scope. 'Wheels are a global business, while the components segment, although substantial, is primarily concentrated in the Americas. From an operational standpoint, we already explore synergies within the Americas,' he explained.

Looking ahead, Klinkers hinted at a potential shift for Iochpe's components business. 'The next big step would be international expansion—moving beyond Brazil and Mexico into global markets. Although we don’t have a specific project in the pipeline right now, internationalising the components business is certainly a strategic option.'

When asked if India could be a focus for this expansion, Klinkers reflected on a previous opportunity with Daimler nearly 10 to 15 years ago. 'We were close to launching a project in India back then, but it didn’t materialise. However, we're always open to exploring new ideas and opportunities when they arise. For now, though, there are no specific projects for components outside the Americas,' he concluded.

Also Read: