Simulation plays a key role in vehicle development at various stages of design and manufacturing.

Yet, it has its own set of limitations/challenges including accuracy and realism, complexity and computational resources, model validation and verification, data availability and quality, and predictive capability.

However, says Aditya Singh, Founding Member and Head of Business, BosonQ Psi (BQP), quantum computing can significantly boost simulation, particularly in solving complex problems which can challenge classical computers,

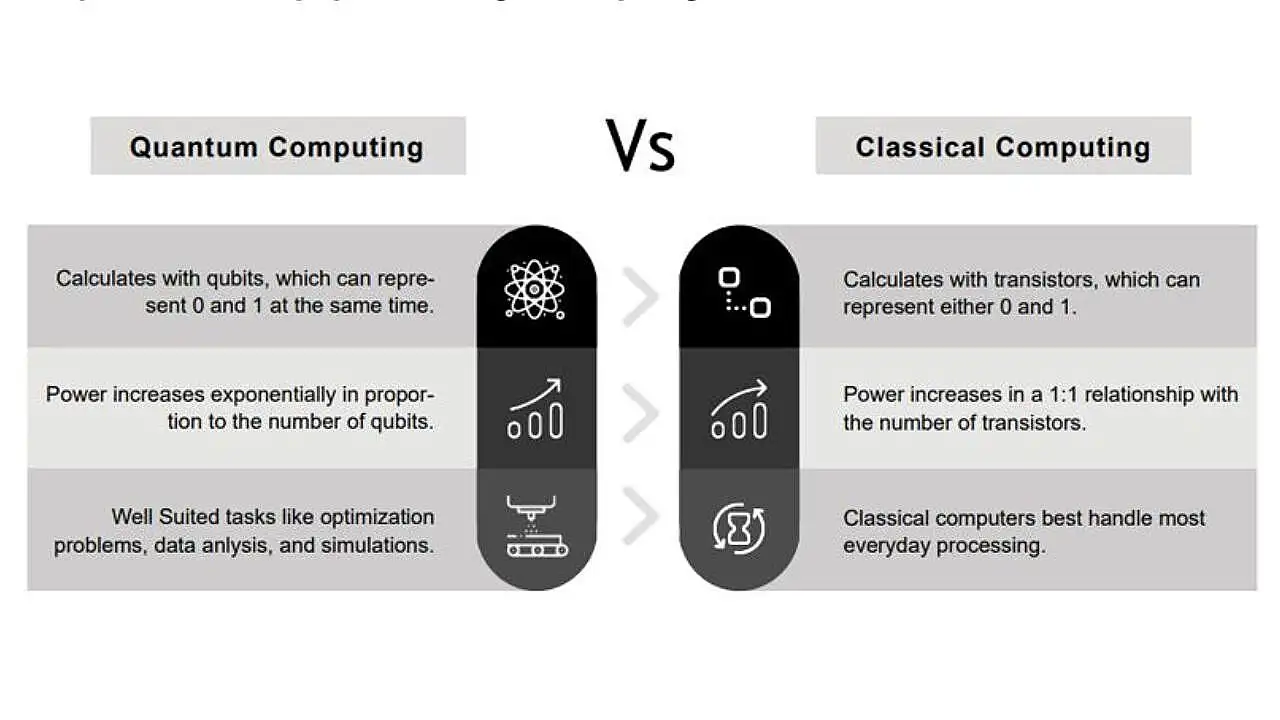

It is the next-in-line technology for computing that leverages quantum mechanics to process and manipulate information. Where classical computers use bits (which can be either 0 or 1) as the basic unit of data, quantum computers use quantum bits or qubits.

Qubits can exist in multiple states simultaneously (everything between 0 & 1 including the two numbers) due to superposition and entanglement. This is the state of one qubit depending on another even when separated by great distances. This unique behaviour enables quantum computers to perform certain calculations faster than their classical siblings.

Quantum computing can transform the mobility sector by optimising material and vehicle design, advancing vehicle innovations like alternative fuels, managing traffic, improving supply chains, enhancing vehicle design, and advancing autonomous vehicles. In a nutshell, it offers more efficient and sustainable mobility solutions.

According to Singh, quantum computers can perform system-level simulations a lot quicker than classical computers. This helps in system-level simulations as against the more complex component-level. Quantum computers can model these systems more accurately and rapidly leading to innovations and advancements in vehicle design, lightweight materials and electric vehicles.

Optimisation Problems

Many simulations involve optimisation tasks such as finding the best configuration among many possibilities. Quantum algorithms can efficiently solve such problems where a large number of variables and complex data sets are involved.

By simulating metaphysics, quantum computing can simulate behaviour and interactions in high-energy, multi-physics environments. This can then design experiments to understand the fundamentals of crash behaviour much better.

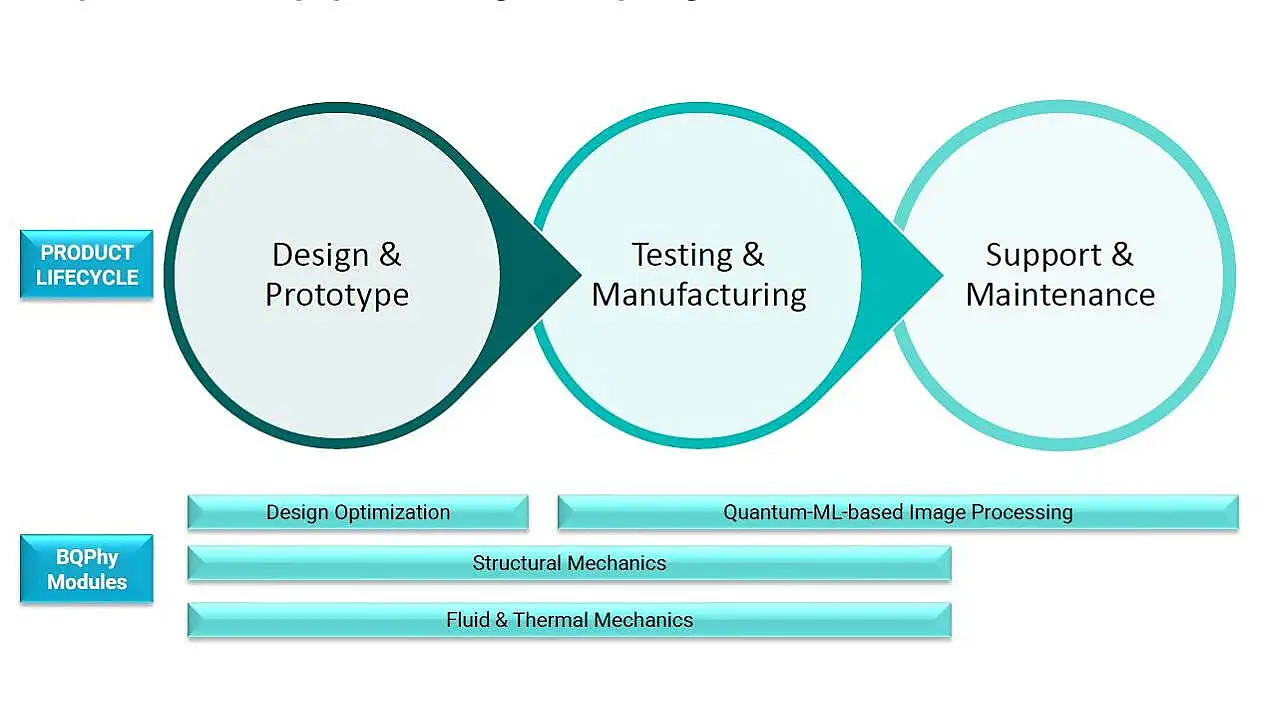

BQP is developing a next-gen engineering simulation software, BQPhy, which leverages the power of quantum computing algorithms for speedy complex engineering simulations. Simulations are critical but “can take infeasible time,” so companies try to oversimplify them. This leads to design inefficiencies or product failures.

Nearly 70% of potential analyses are not done. “Our solution accelerates highly accurate simulations for customers’ products and product developers/avoids costly mistakes,” says Singh.

BQPhy, the CAE software powered by quantum computing to accelerate multiphysics and system-level simulations, is integrated with quantum algorithms that run on current high-performance computers (HPCs). There is no change in simulation experience, tech stack or systems while knowledge of quantum computing is not needed. The BQPhy V1 - quantum-inspired design optimisation module integrates with traditional solvers.

Benefits

The benefits include accurate identification of global minima with more optimal design and fewer design iterations, reducing overall simulation time. Besides, it requires fewer computing resources, eventually reducing the cost of HPC.

Expectations from the engineering team to solve complex design problems, given the conflicting constraints, are immense. The margins are “incredibly small” with the smallest variable having the potential to “massively change” the outcome of the result. Even something as seemingly insignificant as tyre pressure or the weight of a bolt can impact speed and handling of the car.

“This is where faster, accurate simulations are required when companies go all out on innovating something like a lightweight, faster EV that can withstand a crash impact and mitigate thermal runway problems,” explains Singh.

Unlike traditional design processes, simulations combined with quantum computing algorithms can be applied in many ways. Teams involved can perform simulations faster with higher accuracy and faster turnaround than what is possible with classical computers. Therefore, designs can be tested, validated and delivered much faster, reducing the overall cost of production and reducing the engineering lead time.

Design for manufacturing, design for assembly and design for service are the three basic elements for any OEM or Tier-1 supplier. However, to grab the sweet spot in achieving all objectives is a huge challenge. Singh says achieving this elusive ‘radial centre’ requires a delicate equilibrium of design considerations and quantum algorithms running on current HPCs.

BQP’s simulations can help in complex optimisation where quantum algorithms can solve related problems. They analyse design variables simultaneously while seeking the optimal configuration that balances manufacturing efficiency, ease of assembly and serviceability. This helps fine-tune designs to hit the ‘sweet spot’ faster in fewer iterations as simulation efficiency increases.

The parallel processing, where the simulations based on quantum leverage the power of superposition and entanglement, allows for parallel processing of multiple design scenarios. This property allows the processing of terabytes of diverse data much faster. It reduces the time needed to explore a wide design space and helps in quicker decision-making.

According to Singh simulations based on the quantum approach support iterative refinement much faster than traditional approaches. This allows automakers to explore a range of design iterations much faster. This approach also facilitates a more informed and data-driven decision-making process.

In addition, quantum machine learning provides a higher level of precision in predicting how design changes impact manufacturing, assembly and serviceability. This ensures that decisions are based on a robust understanding of the consequences.

By helping automotive companies streamline their design processes, quantum simulations contribute to resource efficiency. This can result in cost savings and reduced environmental impact.

Averting Potential Risks

Quantum simulations help automakers identify potential risks and challenges in the design phase. It allows them to address issues before they become costly problems, thereby enhancing product quality and reliability. As quantum tech matures, auto companies will experience its power and Singh says BQP can help them become future-ready.

Quantum computing can provide significant advancements in processing power and optimisation. Quantum-powered simulations and algorithms can help in training autonomous vehicles, designing software defined vehicle (SDV) architectures and enhancing manufacturing processes.

Taking a cue from IBM, a leading player in quantum computing, Singh says the company is using quantum technology to help the auto industry solve EV and traffic-related problems. BMW has partnered with quantum computing company, Pasqal, to leverage quantum processors for better manufacturing processes. This eliminates the need for physical prototypes and allows simulation of new materials.

Such collaborations demonstrate the increasing focus on quantum computing within the automotive industry. Its ability to handle complex optimisation problems and perform rapid analysis can be used to design advanced SDV architectures. The simulations can find optimal configurations, thereby reducing development time and enhancing overall performance SDVs. Moreover, continues Singh, quantum algorithms can contribute to training artificial intelligence and autonomous systems.

While still in its early stages, the potential impact of quantum computing technology, especially in SDVs, is being explored and researched by industry leaders and experts. It could become an “essential tool” for carmakers in their journey towards SDVs.

Also Read:

Simulation Is At The Core Of Developing Sustainable Products

RVW Conference Highlights The Importance Of Simulation Testing