Henkel Anand India Private Limited (HAIPL), a leading supplier of BIW products and solutions to major OEMs in the country, wants the OEMs to see it not just as an expert in sealants, structural and glazing adhesives, and NVH components but as partners for vehicle safety and comfort requirements. To stay ahead, the company is also developing battery cooling plates for electric vehicles.

This transformation is fuelled by its approach to getting involved with OEMs right from the design phase and “seeing how we can provide them a complete, full-scale solution for all their sealing requirements,” Gurmeet Kaur, Chief Operating Officer, Henkel Anand & India Head, Automotive OEMs, told Mobility Outlook.

Evolution From Supplier To Solutions Provider

The company, established in 1997 as a joint venture between Henkel KGaA (Germany) and Anand Group (India), has been continuously translating its know-how and technology expertise into impactful innovations to cater to the evolving needs of the automotive industry.

The automotive industry has undergone a rapid transformation in the past few decades, and car body structures are becoming lighter as strict regulations and demands drive lower carbon emissions. In their efforts to make cars lighter, car manufacturers are pursuing two main avenues: reducing the number of assembled parts and downgauging the thickness.

Kaur explained, “Henkel can partner with the carmakers in their early vehicle design phase to optimise the overall design for weight as well as cost effectiveness, while meeting all the performance requirements”. This proactive engagement can allow for meticulous planning, streamlining product development timelines and preventing crisis management scenarios. In developed markets such as the US and Europe, Henkel’s early engagement in the vehicle design phase helps develop customised solutions that enhance the structural integrity and safety of vehicles, she pointed out.

The Mobility Alliance

In 2019, Henkel tied up with RLE International to set up ‘The Mobility Alliance’ to drive automotive innovation, expand value creation opportunities and become the premier design engineering solution provider for the mobility industry.

The combination of Henkel’s expertise in material science and RLE International’s engineering know-how creates a significant competitive advantage in designing new e-mobility concepts and automotive lightweighting innovations.

RLE’s core business includes effective and technologically sophisticated engineering expertise in vehicle component development and design. This involves concept development, vehicle and safety engineering, electrics/electronics, e-mobility and lightweight design. Combined with its advanced materials know-how in high-performance adhesives and sealants, structural foams and sound deadeners, the Mobility Alliance is the go-to engineering partner and preferred advanced material supplier in the automotive industry, whose mission is to re-imagine vehicle and component designs to deliver net weight and cost savings while meeting or exceeding performance standards, she said.

Expanding Product Portfolio

Over the past decade, the company has expanded its portfolio of acoustic sealing and structural strength solutions for Indian car and commercial vehicle OEMs. This portfolio expansion is driven by the evolving needs of the domestic consumers, who are increasingly prioritising safety and comfort in their vehicles. Its innovative offerings enhance ride quality, safety, and crash resilience, meeting these needs with cutting-edge solutions.

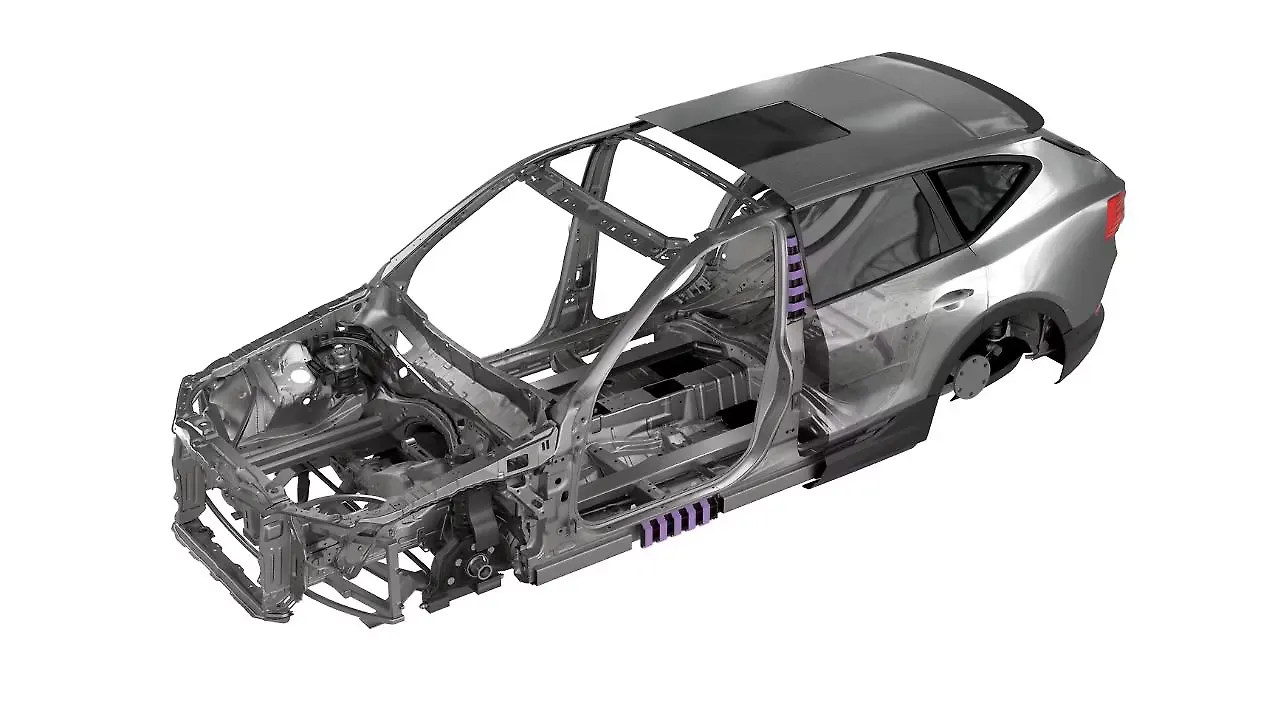

The company’s high-crash-resistant structural adhesives play a fundamental role in meeting crash safety requirements. They are designed to have high fracture toughness to resist cracks, carry a greater load, and diminish impact energy. Structural adhesives also enable lightweighting by joining multi-material parts and allowing them to reduce part thickness.

Enhancing Safety

Engineered for diverse applications, these advanced structural foam materials significantly enhance vehicle safety while simultaneously reducing weight and lowering manufacturing costs. When injection-moulded onto plastic or metal carriers, these three-dimensional structural inserts offer a lightweight alternative to traditional, heavier components such as steel bolts, welds, or panels. Beyond their crash performance, which rivals that of steel, these structural foam materials also provide better insulation, effectively diminishing vehicle noise and vibration. The result is a smoother, more refined driving experience.

Pumpable Solutions

Moreover, Henkel’s pumpable and sprayable solutions represent a significant stride in its commitment to environmental transformation. For instance, using high-expanding pillar fillers offers a substantial vehicle lightweighting advantage compared to traditional injection-moulded nylon baffles. Additionally, in the assembly process, integrating robotic applications can reduce the manual labour associated with baffle positioning by up to 15%, depending on the extent to which pumpable pillar fillers replace nylon baffles across various car lines and labour assignments. This innovation not only advances sustainability but also enhances operational efficiency.

Additionally, a sprayable panel reinforcement solution significantly decreases raw material consumption by enabling panel downgauging and lightweighting. This not only enhances material efficiency but also contributes to ongoing carbon emissions reduction throughout the vehicle’s lifecycle.

For internal combustion engine (ICE) vehicles, lighter panels translate to reduced fuel consumption, while for electric vehicles (EVs), they help lower electric energy usage. During assembly, adopting pumpable and sprayable solutions further minimises carbon emissions by eliminating the need for patch-based cardboard packaging and release paper, which would otherwise contribute to waste. These solutions also streamline operations by reducing complexity and optimising inventory management. Moreover, they dramatically accelerate the design-to-prototype timeline by removing the need for traditional tooling, offering a seamless and sustainable approach to vehicle manufacturing, she added.

Also Read:

Henkel Anand's Digitalisation Efforts Yield Rewards For OEMs