The journey from semiconductors to electronic chips is a story of both innovation and transformation, defining modern technology and industries. Electronic chips—often known as Integrated Circuits (ICs)—serve as the backbone of various sectors, especially the automotive industry. Comprising tiny components like transistors, resistors, capacitors, and diodes, these chips leverage the properties of semiconductors (mostly silicon) to perform core functions in vehicles, including powertrain management, safety systems, infotainment, and autonomous driving. As vehicles evolve to become more digital, connected, and electrified, the reliance on electronic chips grows, extending its impact from design to manufacturing, supply chain, and after-sales services.

Chips As Catalysts Of Transformation

The role of chips in electric vehicles (EVs) is especially notable, as they enable efficient energy management, optimise battery performance, and power digital interfaces that enhance driving experiences. Their presence in EVs also fosters broader sustainability, helping reduce reliance on fossil fuels. This makes chips critical not only to the growth of the EV sector but also to broader sustainable mobility solutions, further amplifying their influence on modern transportation ecosystems.

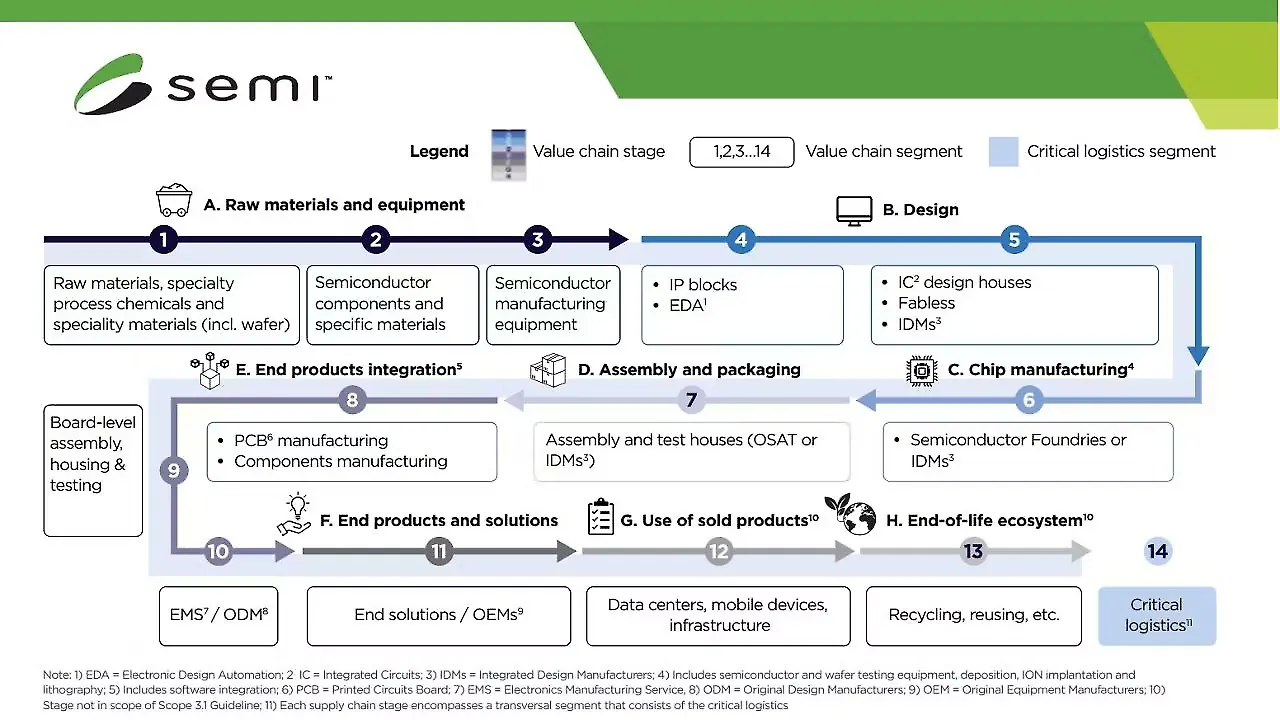

Complexity Of Chip Manufacturing

While electronic chips empower industries, their manufacturing presents unique challenges—especially concerning sustainability. Chip production is resource-intensive, requiring ultra-pure water, rare materials, and an array of chemicals. High-performance chips, which demand exceptional precision, are intolerant to even minute particles, making purity paramount.

Speaking to Mobility Outlook, Mousumi Bhat, Vice President – Sustainability Programs, SEMI Global Headquarters, said, “Historically, semiconductor manufacturing relied on around 50 elements from the periodic table; today, this figure has expanded to entire table comprising of 118. This diversity of inputs adds complexity to sustainable chip production, especially as limited supply of raw materials becomes a growing concern.”

Balancing Resource Consumption With Environmental Output

Sustainability in chip production is not just about reducing emissions but also about the responsible use of natural resources. Water consumption, chemical usage, and emissions are three pillars of this sustainability challenge. Chip manufacturing requires large volumes of ultra-pure water, often sourced from strained water supplies, she said.

Additionally, the industry’s use of chemicals with high global warming potential makes emissions a major concern. Toxic waste generated during production can also harm human health and the environment. As such, sustainability efforts must address the entire lifecycle of chip production, from resource extraction to waste management, she noted.

Assessing Net Impact: Carbon Footprint Vs. Handprint

According to Bhat, evaluating the semiconductor industry’s impact involves a two-sided equation: the carbon footprint, which accounts for emissions and resource consumption, and the handprint, which captures positive contributions.

Chips drive innovations that enhance energy efficiency, optimise resource use, and enable virtual operations that reduce the need for travel. For example, IoT sensors and digital twins—enabled by chips—help manage water usage, monitor waste processing, and optimise energy consumption, she pointed out.

Despite the environmental costs of production, chips contribute positively to society. They enable renewable energy management, reduce the need for physical infrastructure, and support cleaner transport modes like EVs. “Therefore, a complete evaluation of chips’ sustainability must consider both the direct environmental costs and the broader societal benefits they enable,” she said.

Advancing Sustainable Chip Manufacturing

Efforts to make semiconductor manufacturing more sustainable are ongoing but complex. Researchers and industry leaders are exploring alternatives to toxic materials, identifying opportunities to increase energy efficiency, and seeking ways to reduce water usage. However, redesigning chips for sustainability is not a straightforward process; it requires significant investments, innovation, and intellectual capital. Given the intricate nature of nanotechnology, changes to chip design and production must undergo rigorous change management to maintain precision.

India's Semiconductor Opportunity

As per Bhat, India’s emerging semiconductor industry has the chance to embed sustainability from the ground up. Establishing sustainable processes at the start is much easier than retrofitting existing systems. This approach could allow India to become a global leader in sustainable semiconductor production, benefiting from the advantages of modern infrastructure and innovative talent.

The focus should be on fostering an ecosystem where sustainable chip manufacturing becomes the norm rather than the exception. By integrating energy-efficient practices, reducing harmful chemical usage, and exploring renewable energy sources for chip plants, India can create a semiconductor industry that aligns with global sustainability goals.

As chips continue to drive digital transformation across industries, the push for sustainable manufacturing practices will define the future of semiconductor production. The role of electronic chips is undeniable in enabling a cleaner, smarter, and more connected world. As India takes significant strides in developing its semiconductor sector, it has the opportunity to shape a new, sustainable standard for global semiconductor manufacturing—one that balances resource consumption with long-term benefits for society and the planet.

Also Read:

India’s R&D Skills Can Play A Key Role In Chip Mfrg: SEMI Global’s Ajit Manocha