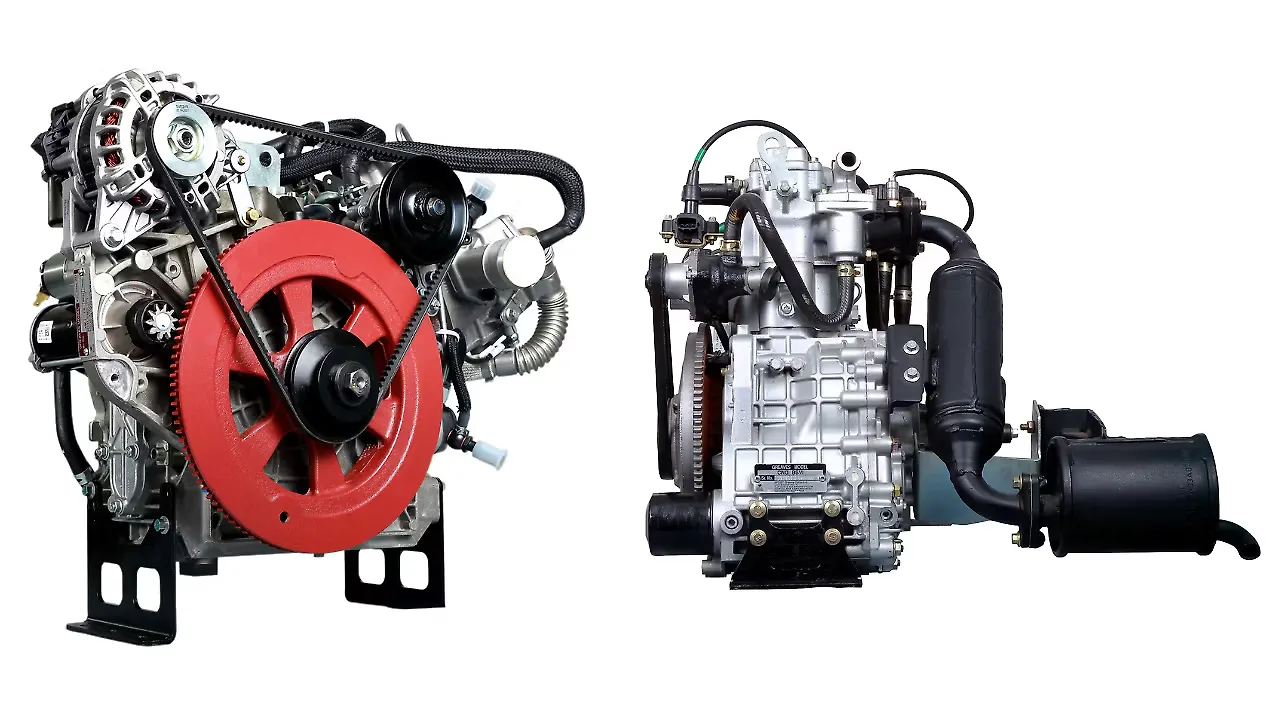

At the recently concluded Bharat Mobility 2025 event, Greaves Cotton unveiled breakthrough innovations: a Euro 5+ compliant single-cylinder diesel engine designed for micro cars, concepts of a 250CC CNG engine and a hydrogen engine for three-wheelers.

Claimed to be a world-first, the Euro 5+ engine aligns with the stringent Euro 5+ emission norms that came into effect in January this year, making it a standout in the competitive Eurozone market.

Speaking to Mobility Outlook, Dr Arup Basu, Managing Director, Greaves Cotton Limited, said, this advanced engine offers several notable features. It boasts excellent NVH (noise, vibration, and harshness) characteristics, ensuring a smoother and quieter performance. With simplified engineering for enhanced efficiency, it delivers the lowest CO2 emissions per kilometre in its category. Despite being diesel-powered, the engine meets some of the world's most demanding environmental standards, demonstrating Greaves’ commitment to engineering excellence.

Expanding Horizons

Greaves Cotton has successfully ventured into the microcar engine segment, establishing itself as a key supplier for European manufacturers, particularly in France. With its Euro 5+ compliant engine—a benchmark for emission norms in Europe—the company has not only met stringent regulatory requirements but also gained valuable expertise in managing noise, emissions, and engine design.

This experience has positioned the company as a leader in advanced engine technology, ready for challenges like OBD 2V compliance, set to take effect from April 1. 'The success of our microcar engine has strengthened our capabilities, and we’re now exploring additional applications where this expertise can be leveraged,' he added.

Greaves Cotton’s portfolio is growing, with engines tailored for specific applications: a 499cc microcar engine for the EU market, a 400cc hydrogen engine, and a 250cc CNG engine. This modular approach allows the company to adapt its innovations across various use cases, ensuring relevance and efficiency in diverse markets.

Fuel-Agnostic Approach

As part of its commitment to a fuel-agnostic approach, particularly in the evolving three-wheeler segment, Greaves Engineering unveiled a 250cc CNG engine prototype. This development aligns with the growing shift in the L5 category, where diesel once dominated, followed by the rise of CNG and electric options.

The new engine is a clean-sheet design, engineered to provide improved performance and economics compared to existing solutions. The company is ensuring its portfolio remains versatile, preparing for any shifts in fuel preferences across diesel, CNG, and electric powertrains.

Hydrogen Engine

While the feasibility of hydrogen adoption in three-wheelers remains uncertain, the development underscores Greaves' focus on building a broad spectrum of capabilities. 'Our goal is not to dictate fuel choices but to offer solutions that meet diverse energy demands,' he said.

Navigating Challenges In Alternative Fuel Adoption

Discussing the challenges of introducing alternative fuel technologies, Basu highlighted two primary hurdles: adoption and engineering. From the customer's perspective, while CNG infrastructure is steadily expanding in line with government plans, hydrogen infrastructure remains virtually non-existent. 'Even if we have a hydrogen engine tomorrow, where would someone go to refill it?' Basu noted, emphasising the need for supply chain innovation, such as developing compatible hydrogen tanks.

On the engineering front, the challenges revolve around combustion design and system reliability, common to any white-sheet engine development. These are not insurmountable issues but require rigorous problem-solving and collaboration with industry partners. Basu acknowledged the ecosystem's capability to meet these demands, supported by a strong history of designing three-wheelers for livelihood-oriented customers.

Reliability and cost-effectiveness remain critical for three-wheelers, as these vehicles are often bought by customers with constrained budgets who rely on them for daily income. 'We can't create gold-plated solutions,' Basu explained, stressing the importance of designing affordable, repair-friendly products. Whether powered by hydrogen, electric, or CNG, the focus is on minimising downtime, ensuring ease of repair, and controlling running costs.

For instance, diesel engines have long been favoured for their simplicity and ease of maintenance. With newer technologies like hydrogen and electric, there’s an added responsibility to ensure the vehicles remain practical and robust, even when sophisticated systems are involved. Safety is another key dimension, particularly for fuels like CNG and hydrogen. While the market has grown accustomed to CNG as a fuel under pressure, hydrogen systems will require further efforts to ensure user safety and build trust.

Navigating Challenges in Technological Advancements: A Customer-Centric Approach

Basu highlighted how Greaves Cotton’s B2B engine business thrives on staying closely connected to its customers, leveraging their insights to guide technological advancements. “Our design and improvements have always been tied to our ability to read weak signals from our customers,” he said, emphasizing the importance of understanding nuanced shifts in customer needs. With a select number of B2B clients, the company dedicates teams to monitor their perspectives and anticipate emerging trends.

Expanding beyond India’s borders has also been a strategic focus. Adopting a 'Make in India, Make for the World' approach, the company is tailoring its products for diverse geographies, moving away from a one-size-fits-all export model. This strategy incorporates insights from price-sensitive domestic markets into international operations, ensuring cost-effective yet value-driven offerings that stand out with clearly defined differentiators. “Our engineering capabilities and market understanding enable us to create sharp differentiators for competitive markets,” Basu added, likening the process to 'mass customization.'

Balancing Standardisation & Customisation

Addressing the extent to which standardisation can be balanced with customisation, Basu noted the company’s focus on building modular platforms. For instance, their internal combustion engine (ICE) platform supports multiple fuel types like CNG, ethanol, and others. To ensure adaptability, Greaves Cotton has restructured its R&D into Centres of Excellence for specialised areas such as electrical systems, electronics, and NVH.

These centres form the backbone of the company’s innovation efforts, while application engineering serves as the customer-facing front end. This dual approach allows for seamless customisation. “We function like chefs, combining the right ingredients to formulate tailored solutions for each customer,” Basu explained. Strategic partnerships also play a role in filling capability gaps, ensuring the company stays aligned with best-in-class standards.

Embedding Sustainability & Innovation

Basu outlined how Greaves Cotton is integrating sustainability and innovation into its operations, leveraging an ESG framework to drive environmentally responsible practices. 'Our manufacturing processes are guided by metrics such as water, carbon, and overall manufacturing footprints,' he noted. While the journey is evolving, early metrics are being established to track progress, with plans to refine them as the framework matures.

In the realm of materials, Basu highlighted the shift from traditional metal-heavy designs to advanced polymers and alternative materials. These advancements enable significant weight reduction, contributing to better fuel efficiency and performance. 'Value engineering is ingrained in our culture of continuous improvement—it’s not just about cutting costs but enhancing performance,' he said.

Basu also emphasized the role of regulatory changes in driving engineering innovation. As India transitions through stricter norms like B-6 and B-7, the company views these regulatory milestones as opportunities to rethink and innovate. 'You can't meet tomorrow's norms by doing the same thing. These changes push us to evolve and engineer for the future,' he explained.

When it comes to manufacturing, the challenge lies in scaling customisation within a mass production framework. For instance, Greaves Cotton has adopted a modular approach, enabling efficient, reliable, and safe production across product lines, including electric vehicles. Basu stressed the importance of designing manufacturing lines and collaborating with multiple designers to ensure sustainability and scalability.

Diversifying Growth With Strategic Expansion

Greaves Cotton is strategically expanding its footprint by diversifying into new areas, including motor controllers and e-powertrain solutions, while ramping up its export portfolio through geographic diversification. This multi-pronged approach is aimed at accelerating growth and tapping into emerging opportunities.

A notable addition to the company’s portfolio is Excel Control Linkage, acquired a few years ago. This company specialises in controls for accelerator, brake, clutch, steering, gear, and parking brakes—components essential for both electric and ICE vehicles. This acquisition sharpens Greaves Cotton’s focus on adjacencies that complement its core business, enabling sustainable growth across various applications.

Additionally, the company has begun assembling motors in-house and is gradually scaling up its offerings, including plans to venture into e-axle manufacturing. As the market shifts from component demand to sub-assemblies, the company is evolving its capabilities to align with industry trends. Combined with its focus on export growth, this diversified strategy represents the company’s key growth vectors for the future.

Also Read:

Greaves 3 Wheelers Partners With Shriram Finance To Support Electric 3-Wheeler Adoption