General Electric (GE) Aviation’s Catalyst advanced turboprop engine is a powerplant expected to revolutionise the light aircraft market. As the first clean-sheet turboprop engine design in 30 years, the GE Catalyst incorporates 98 patented technologies and benefits from its lead in additive manufacturing technologies and its extensive experience in manufacturing turbofan engines for civilian jetliners.

The engine’s launch customer, Textron Aviation, completed the first flight of its all-new single-engine Beechcraft Denali aircraft earlier this week. The Catalyst engine powers the Denali to a cruise speed of 285 knots with four passengers and a pilot on board. The aircraft can attain a range of nearly 3,000 km while carrying 500 kg of fuel.

Advanced Powerplant

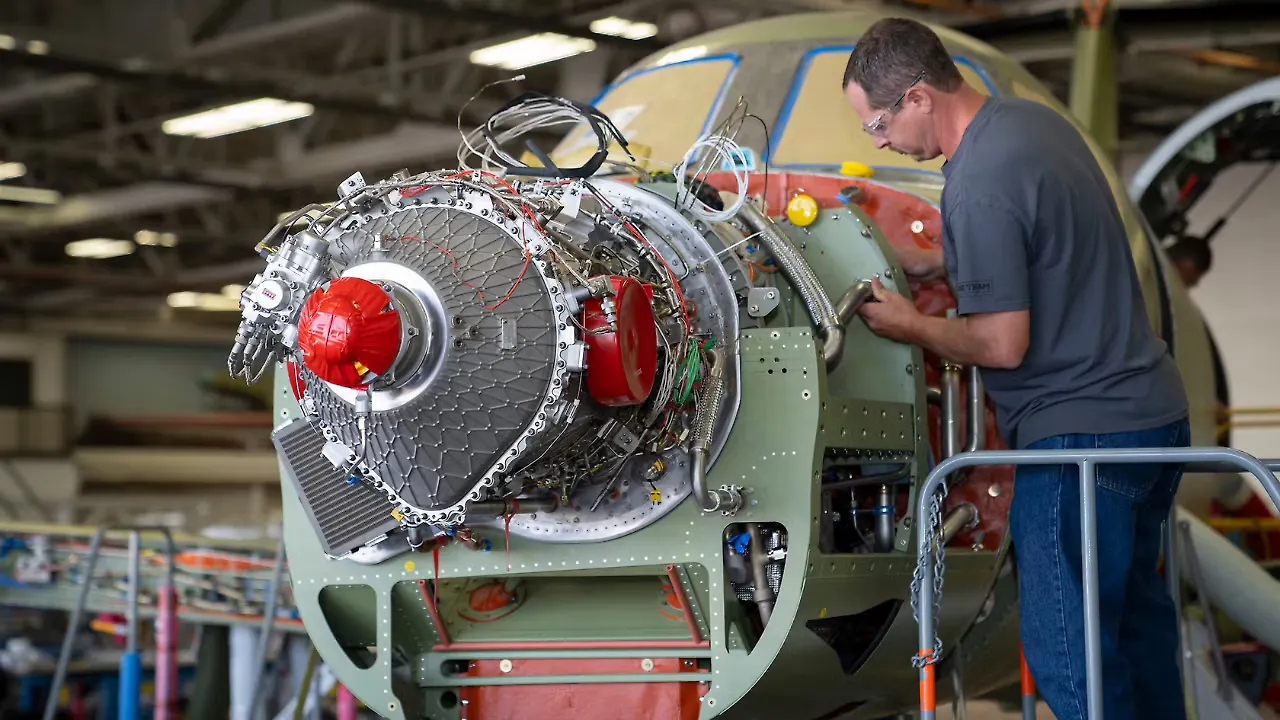

The GE Catalyst is the first turboprop engine to make extensive use of 3D printed components, which have reduced engine weight by 5% and improved Specific Fuel Consumption by 1%. GE used additive manufacturing to make 12 parts, replacing what would have earlier amounted to over 800 separate components made using conventional methods. These 3D printed parts are lighter and have tighter tolerances, delivering enhanced reliability and longer engine life with lower maintenance. It has also disrupted the whole production cycle for engine development. Previously, a similar engine class would have taken approximately ten years, but Catalyst was developed in half that time.

Despite its American roots, GE Aviation’s supply chain and assembly facilities for the new engine are based in Europe, with the involvement of GE Aviation Czech, Avio Aero of Italy and Poland, GE Aviation Advanced Technology of Munich (Germany) and GE Engineering Design Center of Warsaw (Poland). The engine was developed entirely in Europe, apart from some testing in Canada.

Change Agent

The GE Catalyst is the company’s first modern Full Authority Digital Engine Control (FADEC) controlled turboprop, representing a significant advance for commercial turboprop engines. However, the technology is commonplace on jet engines used in aircraft and turboshaft engines used in helicopters. This is the first instance of FADEC use in a commercial turboprop engine.

Paul Corkery, GM, Turboprop Engines, GE Aviation, said, “The FADEC knows the conditions my plane is in, and it then optimises the pitch of the propeller and the fuel flow around those conditions. The pilot will no longer need to consult a chart to optimise the flight around the correct parameters with four separate levers. It will all be digitised. The pilot will just have a single lever. It will be like flying a jet.”

The Catalyst features an Integrated Propulsion Control (IPC) system with a single electronic engine and propeller control lever. Other digitally-enabled features include engine auto start with automated exceedance protection and integrated propeller control. The FADEC system uses two fully redundant computers to control the engine and the propeller. The computers obtain their data on speed, air temperature and density, altitude and several other parameters from sensors placed on the aircraft. As a result of FADEC, the pilots no longer need to keep fine-tuning engine and propellor settings, thereby reducing their workload.

New Era

GE Aviation officially launched its Advanced Turboprop (ATP) engine programme in 2015 and named the engine ‘Catalyst’ in March 2018. Engine ground tests started in December 2020, with the new engine taking to the air for the first time this September. GE Aviation has already completed over 2,600 hours of engine operation in ground tests. The first flightworthy engine was delivered to Textron Aviation in 2020.

The engine features an industry-leading overall pressure ratio of 16:1, allowing increased pressure and temperature, enabling the fuel to burn more efficiently and delivering more power and speed at altitude. It reduced CO2 emission by 20% against current turboprop engines in the same class. The new engine also offers 4,000 hours between overhauls, which is 33% better than its leading competitor.

Predictive maintenance will be another first for the engine class. Sensors in the engine will capture part-level performance characteristics for OEM needs, while Catalyst’s fully integrated digital control system will collect performance data during each flight. This data will be used to determine the aircraft’s flying environment, along with the health of the engine, controls and accessories. Operators will also be able to receive alerts specific to engine serial numbers sent by GE Aviation.

The aircraft data collected will be used to create a virtual simulation – or a “digital twin” – of every Catalyst engine that enters service. To compare the actual versus expected performance of the machine, operators will be able to add additional data such as weather, flight and fleet details. According to GE Aviation, a digital twin is currently not available on any other civilian turboprop for preventative health maintenance.

The Catalyst will provide GE with opportunities in the business and general aviation market and for military applications like drones and trainers.

“As the first turboprop ever fully designed, developed and built in Europe in the last half-century, the Catalyst engine is an ITAR-free product also available for military applications,” said Pierfederico Scarpa, VP Marketing & Sales of Avio Aero, a GE Aviation company, which helped design the engine and critical parts like its gearbox, the FADEC and high-pressure turbine components. The Catalyst engine will meet power requirements for aircraft classes in the 850 -1600 SHP range. Catalyst’s super-efficient core could also pave the way for a future hybrid powerplant. The engine will run on Sustainable Aviation Fuel (SAF) and could also go on to power new types of unmanned aerial vehicles and hybrid aircraft.