In a world striving for carbon neutrality, Cummins’ ‘Destination Zero’ strategy is a significant declaration that a sustainable future cannot be left to chance. The path to zero emissions is a journey, not a sudden transformation, requiring innovative technologies that balance immediate energy needs with long-term environmental goals. Recognising that the global shift to zero-carbon mobility cannot happen overnight, Cummins is integrating a wide spectrum of advanced power technologies, each taking the industry closer to a cleaner, greener future.

At the heart of this transition, internal combustion engine (ICE) technologies continue to play a crucial role. Cummins believes that advanced diesel, natural gas, and hydrogen-powered ICEs are essential stepping stones towards net-zero carbon emissions by 2050. As part of its Destination Zero strategy, the company has set an ambitious interim goal—reducing greenhouse gas emissions from newly sold products by 25% by 2030.

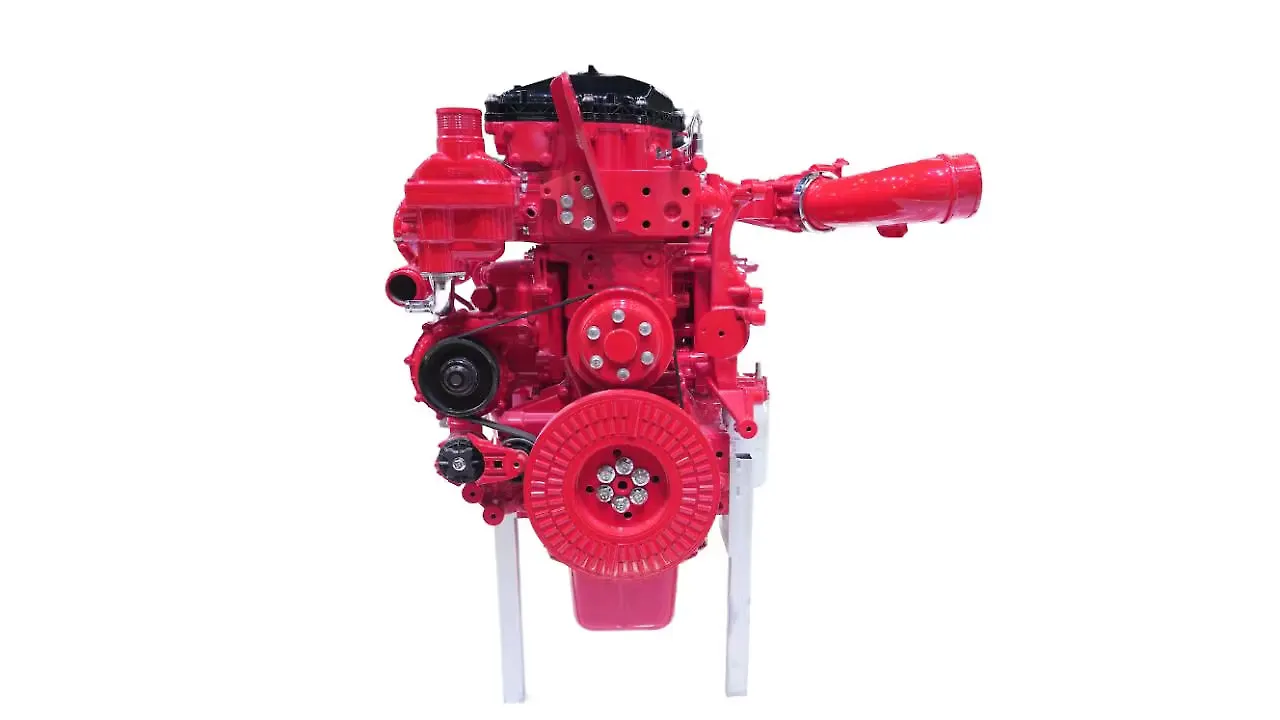

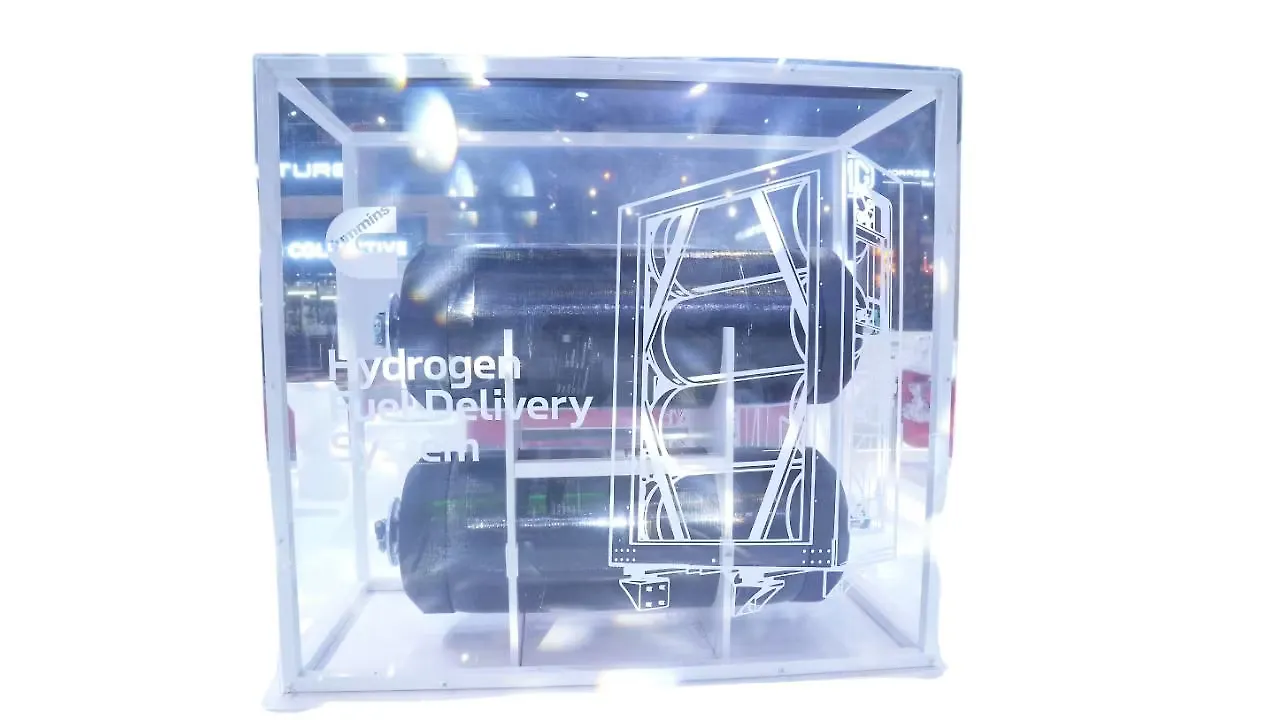

Furthering its sustainability roadmap, Cummins Group in India made a strong impression at the Bharat Mobility Global Expo 2025, unveiling its next-generation HELM (Higher Efficiency, Lower Emissions, Multiple Fuels) engine platforms. The showcase featured the high-performance L10 engine, a cutting-edge Hydrogen Fuel Delivery System (FDS) with Type IV storage vessels, and the innovative B6.7N natural gas engine. These platforms highlight the powertrain maker’s focus on performance, adaptability, and sustainability, providing fuel-flexible solutions that cater to diverse operational needs while aligning with evolving environmental regulations.

Redefining Sustainability Across Manufacturing Value Chain

Speaking to Mobility Outlook, Jonathon White, VP – EBU Engineering, Cummins Inc., highlighted the company's holistic approach to sustainability, stressing that its Destination Zero vision goes beyond product innovation to encompass greener manufacturing processes.

“Our focus on Destination Zero is not just about the final product but also about the processes we use to build it. Achieving zero emissions is not a ‘light-switch event’ for Cummins or the industry—it’s a journey. From manufacturing to real-world application, we are committed to reducing CO2 emissions across the entire value chain, following a true ‘well-to-wheels’ approach,” White explained.

Cummins has been actively working towards CO2 reduction for more than a decade, steadily implementing internal greenhouse gas reduction goals and sustainable innovations. White reaffirmed the company’s ambitious vision: “By 2040, our aim is to reach true zero emissions—both in our manufacturing and across our products in real-world applications. While this is a monumental challenge, every step we take today brings us closer to that reality.”

Balancing Sustainability & Cost

While the vision of sustainability is compelling and the transition to cleaner mobility is inevitable, the real challenge lies in cost acceptance. For commercial vehicle operators, the fundamental question remains—how does sustainability translate into profitability? At the end of the day, the cost of ownership is paramount for fleet owners and logistics businesses, who operate on tight margins and depend on efficient, cost-effective power solutions.

Acknowledging this reality, Cummins has strategically designed its Hydrogen Internal Combustion Engine (ICE) to deliver performance on par with diesel while integrating sustainability into the equation. Addressing concerns over adoption costs, White emphasised that cost efficiency remains a core focus in the company’s Destination Zero strategy.

“Our journey toward zero emissions must be aligned with economic viability for our customers. While the availability of clean hydrogen and robust infrastructure will play a key role in determining the pace of adoption, we are ensuring that our fuel-agnostic engine platforms provide a seamless transition from conventional diesel engines. By maintaining familiarity in design and operational efficiency, we aim to scale these solutions affordably, keeping costs within acceptable limits for businesses,' White explained.

Cummins’ approach ensures that commercial fleet operators don’t have to choose between sustainability and profitability. By integrating low-emission technology without compromising performance, the company enables businesses to achieve their environmental goals while maintaining operational success. The road to zero emissions, while challenging, is being built with practical, scalable, and cost-effective solutions—ensuring that sustainability makes business sense for the customers who power the world’s supply chains, he pointed out.

Navigating Crossroads

For companies like Cummins and major vehicle manufacturers, the path to sustainability is riddled with complex challenges. The challenge is not just about choosing the right technology but about delivering solutions that align with infrastructure realities, cost considerations, and long-term sustainability goals.

Addressing these challenges, White elaborated on the company’s approach, emphasising that flexibility is key. “We unveiled our HELM engine platform, alongside zero-emission electric axles, battery-electric, and hydrogen-based solutions. While we don’t have a fuel cell showcased today, it remains an integral part of our portfolio. Our ultimate goal is to provide customers with options—allowing them to choose the powertrain solution that best suits their business needs while driving towards a cleaner, greener future,” he explained.

However, fossil fuel engines still have a role to play. While hydrogen and battery-electric vehicles are the future, infrastructure readiness and total cost of ownership remain key hurdles. White acknowledged that many of Cummins’ customers rely on business sustainability just as much as environmental sustainability. “They need solutions that are practical and financially viable. As we continue enhancing fossil fuel efficiency, these engines will serve as a bridge until cleaner energy sources become widely available and cost-effective,” he added.

Beyond powering cleaner vehicles, Cummins is equally focused on greening its own manufacturing footprint. The company has implemented carbon reduction initiatives across all its existing plants, with every facility committed to year-on-year improvements in emissions reduction. Meanwhile, new plants are aligned with stringent sustainability targets, ensuring that as the company transforms its product portfolio, it also minimises its own environmental impact.

By pioneering practical, scalable, and high-efficiency solutions, the company is setting new benchmarks for the industry, proving that the road to zero emissions is not a distant aspiration, but a journey already in motion.

Also Read:

How Cummins Is Future-Proofing Engines With Modular Valvetrain Technology