Embarking on his journey in software development several years ago, Jean-François Tarabbia, the Head of Architecture and Networking at Continental AG, reminisces about a time when the industry pondered the separation of software and hardware. Today, as the industry stands on the cusp of this transformation, Continental is actively steering in this direction, acknowledging the challenges of this transitional phase.

At the heart of this evolution is the strategic organisation of business areas, with a dedicated unit positioned to pave the way for the future as an enabler. Tarabbia oversees this business area, which encompasses computing, machine-to-machine communication within and outside vehicles, and robust data management, including high-performance computers (HPCs) and telematics. Complementing this core are various business areas from other divisions, integrating functions such as driving assistance, safety, and user experience.

While the focus is firmly oriented towards this innovative approach, it's crucial to recognise that the automotive landscape is in a transition phase. Legacy products will persist for a while, and the industry grapples with finding the right balance. Some customers have successfully embraced the separation of hardware and software, but many are still navigating this intricate terrain, striving to uncover solutions that truly add value.

In this dynamic scenario, Continental's role is pivotal. Their expertise is not just in providing cutting-edge solutions but also in advising customers, helping them optimise their approach, and implementing solutions that align with their unique needs. Today, the automotive industry stands at the crossroads of innovation and tradition, and Continental is actively guiding its partners toward a future where the synergy of hardware and software creates unparalleled value.

Meeting Ever Evolving Customer Expectations

Companies such as Continental face the challenge of developing technologies that evolve rapidly, even before they enter series production, due to shifting customer requirements and expectations. Predicting and responding to these dynamic expectations present an ongoing challenge.

Drawing from his experience, Tarabbia highlights the intricacies involved, especially in product development. Using the example of displays, he recounts instances where proposing new technologies precedes OEMs evaluating their value for end customers. Transitioning from analogue to digital clusters, the crucial decision-making on when to introduce these changes lies with OEMs, who assess market demand. Understanding customer willingness to pay for specific features, like a different display or the importance of a tachometer, becomes essential market insight.

In the realm of traditional products, there exists a delicate interplay between market demand (‘market pull’) and technological innovation (‘techno push’). Exploring new architecture involves OEMs anticipating how they can continually upgrade and update car functionalities throughout its lifespan, which necessitates the separation of hardware and software. Compliance with regulations, particularly in areas like cybersecurity, becomes a critical factor in maintaining a car's security standards over many years of use, he says.

The challenge extends to defining a business model, especially in comparison to the unique approach adopted by Tesla. The ambiguity in how customers perceive and pay for upgrades or additional functions complicates matters for the broader automotive industry. While Tesla sets a distinct example, the rest of the industry grapples with determining the practicality of implementing a full Software Defined Vehicle (SDV) architecture across all car products. The current landscape finds OEMs seeking clarity on the commercial benefits of this comprehensive approach. As the industry navigates these complexities, the question of how to leverage SDV architecture for cost-effectiveness remains a pivotal consideration in the evolving automotive landscape, Tarabbia mentions.

Artificial Intelligence

Artificial Intelligence (AI) has become a pervasive topic, and when discussing its role in the automotive industry, particularly from a Tier-1 company perspective, Tarabbia emphasises its significant impact. Within their products, AI plays a substantial role, particularly in driving assistance, where AI and machine learning are integral components of Advanced Driver Assistance Systems (ADAS).

AI algorithms are crucial for optimising performance, especially when confronted with a diverse range of use cases. Whether designing a product or employing a calibration approach, Continental leverages AI to navigate the complexities of various scenarios and determine optimisation strategies. 'We use AI to enhance system performance and safety. Another crucial aspect of our development involves ensuring compliance with country-specific regulations,' Tarabbia explains. The investigation into how AI can assist in covering diverse regulatory frameworks is ongoing, reflecting the increasing integration of these technologies in automotive processes.

Despite the evolving nature of regulations based on technological challenges and situations, Tarabbia acknowledges that the industry often finds itself ahead in innovation by the time regulations are formulated. Striking a balance between innovation and compliance, he draws a parallel with a vaccine, emphasising that the benefits of AI outweigh the potential negative impacts. Acknowledging the inherent risks associated with this novel approach in the industry, he expresses surprise at its effectiveness. This adaptive approach, according to Tarabbia, is crucial to ensure that regulations keep pace with technological advancements.

Aiding Manufacturing

From a manufacturing perspective, the integration of machine learning has significantly enhanced resource optimisation and sustainability in operations. Tarabbia elaborates on this, stating, “We extensively leverage AI in manufacturing, with a notable application being optical inspection. Specifically, after the pick and place and soldering processes, we employ a vision system, known as Automatic Optical Inspection (AOI), which now incorporates AI for issue identification. This extends beyond visual inspection, as we analyse various parameters throughout the production line. Utilising machine learning, we scrutinise potential factors that, individually, may seem within acceptable limits but, when combined, could lead to unexpected issues. This approach allows us to detect and address issues that conventional methods might overlook. The possibilities seem boundless, offering a pathway to continually enhance quality, streamline production line performance, and ultimately elevate the overall product quality.”

Server-based Architecture

Regarding server-based architecture and the pivotal role of high-performance computing, Tarabbia emphasises the inherent flexibility arising from the separation of hardware and software. However, he underscores the need for strategic hardware investments in computing, memory, connectivity, and power to effectively anticipate future requirements. The challenge lies in finding the delicate balance between investing in potential features and ensuring equitable compensation for these features—a complex equation that OEMs grapple with.

The server approach aims to achieve scalability not only at the central server level but also at the zone control modules. An innovative hybrid solution is proposed, preserving some computing power in the zone control modules, albeit in a small HPC format. These modules effectively manage numerous inputs and outputs for sensors and actuators. Recognising the absence of a one-size-fits-all solution, Tarabbia stresses the ongoing need for balance, optimisation, and a diverse toolbox of solutions.

However, adopting such varied solutions raises concerns about losing the advantages of standardisation and economies of scale. Tarabbia acknowledges this drawback but delineates Continental's strategy. Internally, they focus on creating small building blocks and an architectural framework, implementing these blocks across various configurations, such as three zone control modules and one or two HPCs. This internal standardisation within Continental facilitates efficient management.

On a broader industry scale, Tarabbia recognises the challenges of achieving standardisation. While industry standards like AUTOSAR exist, the multitude of implementations and variants complicates matters. Continental engages in collaborative efforts with key customers to establish industry standards. Despite acknowledging the complexities, he expresses hope that, gradually, key players will understand the collective interest in converging toward standardisation, especially in the middleware—a framework that should evolve into a more standardised industry component.

Hence, “our collaboration includes Elektrobit and Argus for cybersecurity. By integrating their expertise with the hardware solutions we offer, we optimise the overall solution to meet market requirements,” he says.

Squeezing Time To Market

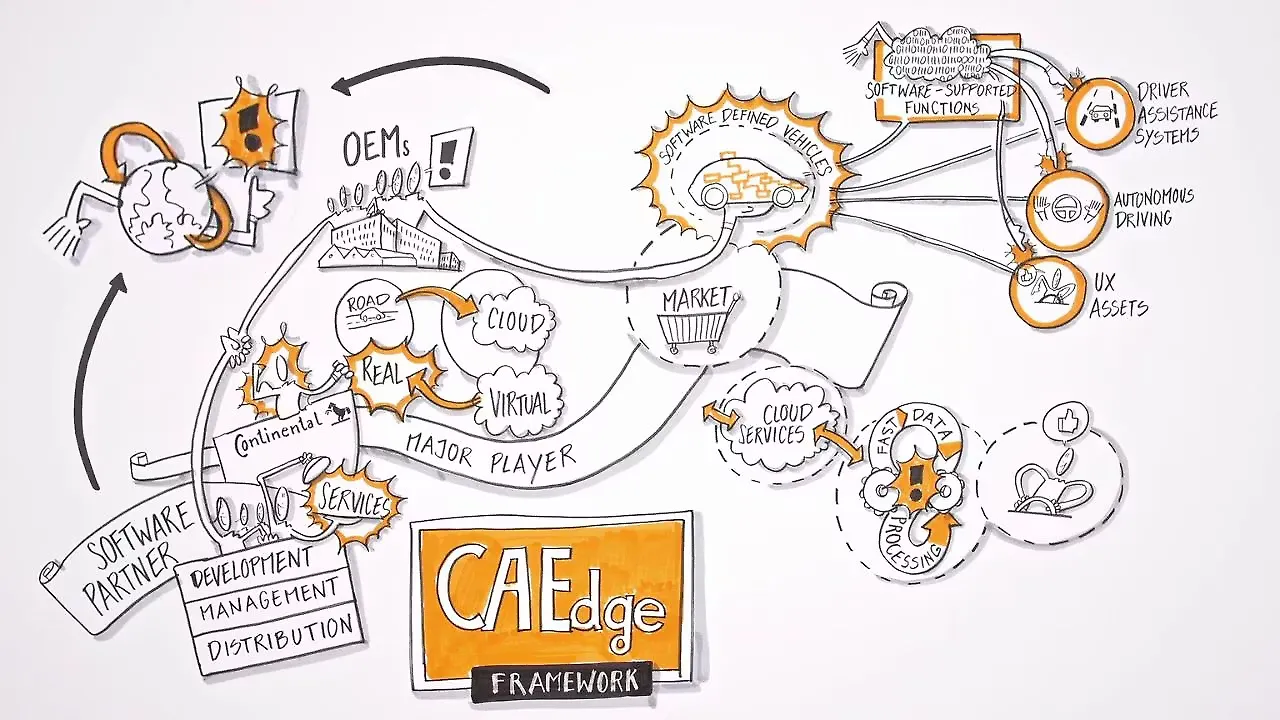

Accelerating time to market is paramount in today's landscape. Has Continental embraced innovative technologies for expedited simulation in product development? According to Tarabbia, the company is actively pursuing virtualisation. When dealing with hardware, middleware, and applications that need simultaneous validation, synchronising every element can be challenging. The solution involves implementing a virtual machine that generates hardware and software simulations, enabling functionality testing even before the complete interface is established. This initiative, known as CAEdge (Continental Automotive Edge), combines hardware reference, middleware, and cloud-based simulation, forming a tool chain for what Continental terms ‘virtualisation.’

Another challenge arises in adding more features to entice customers within the confines of fixed vehicle dimensions. The key is integrating the car fully into the digital ecosystem, particularly for the younger generation that values smartphones. Continental's mission is to facilitate this integration while ensuring the car maintains quality, safety, and security. Striking the right balance in competitiveness requires standardisation, making Continental a key enabler in navigating this challenge.

Also Read:

Continental Engineering Services: A Specialised Force Driving Innovation