In a significant leap towards sustainable transportation, the joint venture between Daimler Truck AG and the Volvo Group, known as cellcentric, has inaugurated its pilot production for fuel cell systems at the Esslingen-Pliensauvorstadt site. This marks a crucial step towards large-scale production, with the company aiming to supply fuel cells on a mass scale by the end of the decade, aligning with the predicted rise of fuel cell-powered long-haul heavy-duty trucks.

Founded in 2021, cellcentric leverages a wealth of expertise, backed by around 700 individual patents, acquired from decades of fuel cell system development by its predecessor companies. The company is dedicated to developing, producing, and distributing fuel cell systems in Baden-Wuerttemberg, Germany, targeting the best possible total cost of ownership (TCO) in the competitive transportation industry. Beyond production, the company aims to cover the entire fuel cell ecosystem, from product development to maintenance and end-of-life recycling.

“Fuel cell technology is a well-proven solution for CO2-neutral long-distance heavy-duty transportation. However, it has not yet been produced on an industrial scale, which is key to achieving economies of scale, optimizing TCO, and securing a competitive position long-term,” says Lars Johansson, Chief Commercial Officer and Chief Organisational Officer of cellcentric GmbH & Co. KG. He adds, “The opening of our pilot production facility in Esslingen today is not the end point but the blueprint for the next step. We will continue to drive forward the industrialisation and scaling of fuel cell system production at the Weilheim site in the coming years.”

Modern Production Facility, Comprehensive Ecosystem

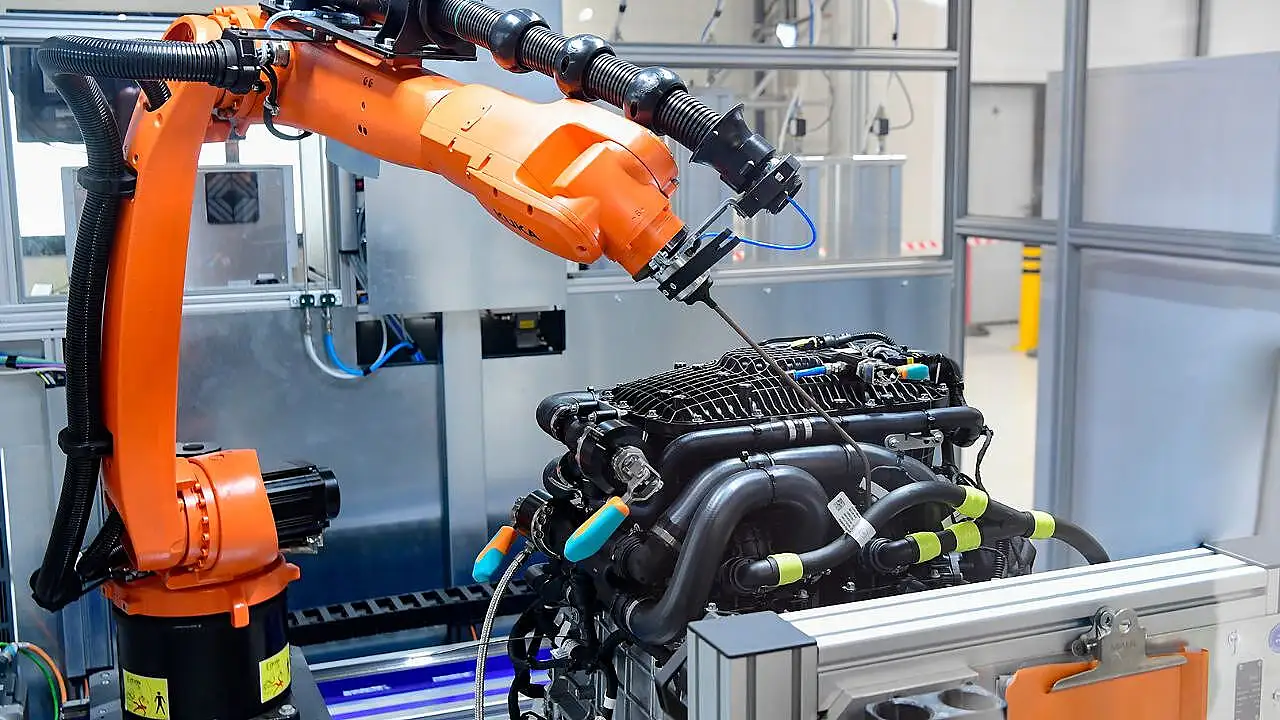

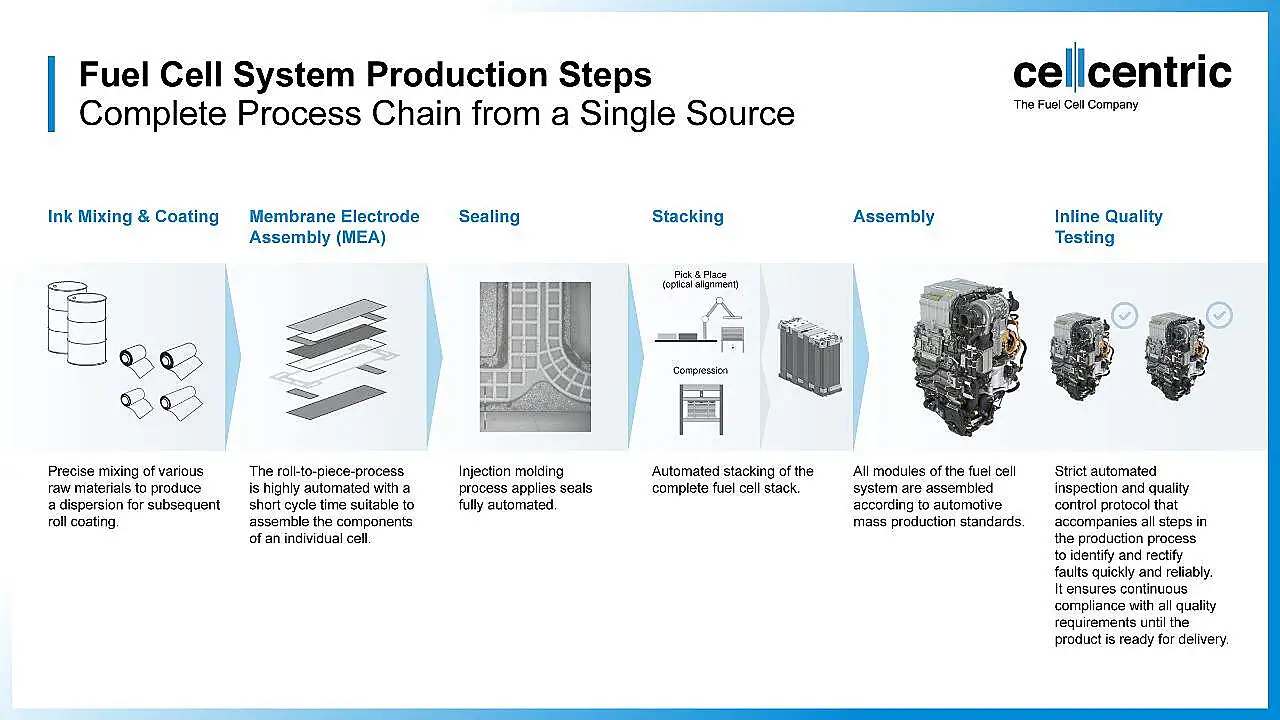

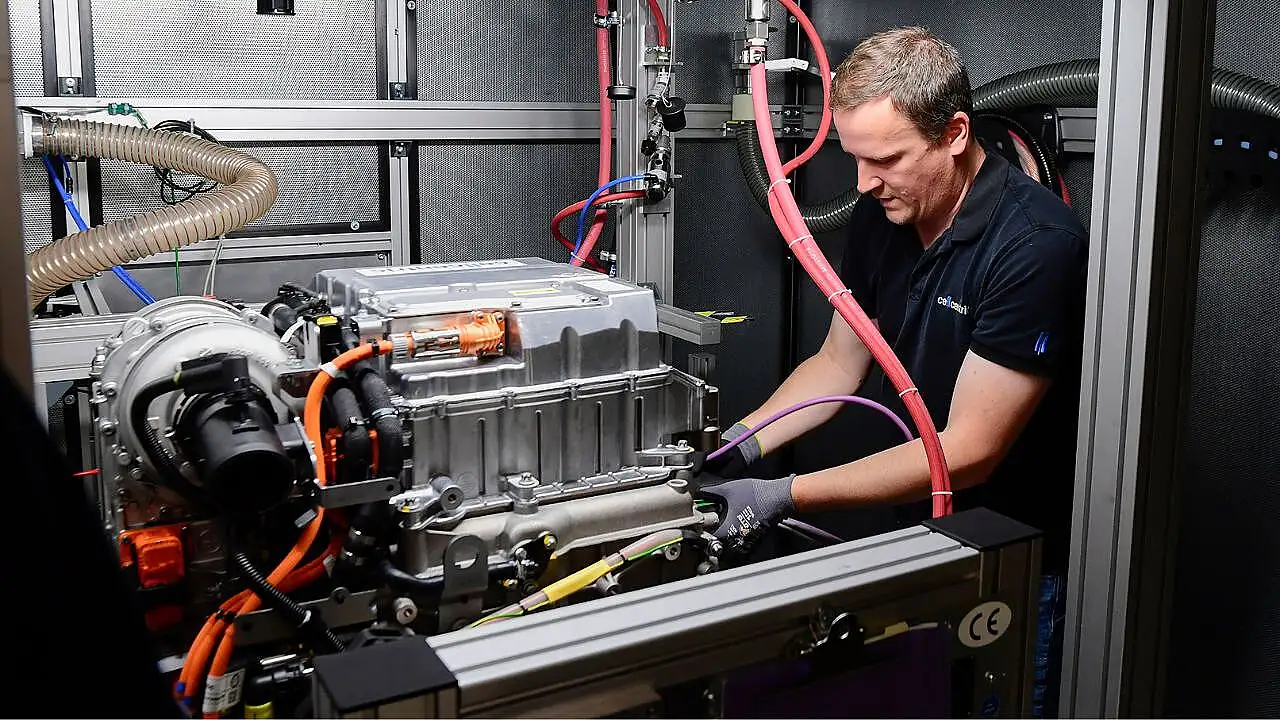

The state-of-the-art production facility in Esslingen-Pliensauvorstadt, spanning over 10,300 square meters, is equipped to produce fuel cell systems efficiently. With more than 100 employees, the facility is strategically located in the Esslingen industrial park greenfield, near federal highway 10. This modern setup is designed to establish production processes that prepare for large-scale production with a high degree of vertical integration, ensuring stable long-term economic development.

cellcentric’s approach extends beyond manufacturing. The company is developing a complete ecosystem around its fuel cell systems, offering quality products and seamless integration into vehicle management systems. A comprehensive service package will minimise maintenance-related downtimes and unexpected failures, ensuring optimal vehicle capacity utilisation. Additionally, the company aims to follow environmentally friendly practices, planning for the reuse, refurbishment, remanufacturing, and recycling of fuel cell systems at the end of their lifecycle.

Cutting-Edge Innovations, Strategic Vision

In May 2024, cellcentric unveiled its NextGen fuel cell system at the ACT Expo in Las Vegas, USA. This smaller, more efficient system is designed for hydrogen-powered long-haul trucks and has been successfully tested by Daimler Truck and Volvo Group in demanding field tests. Series production of the NextGen system is scheduled to begin by the end of the decade, signaling a major advancement in sustainable heavy-duty transportation.

Strategy Behind The JV

The formation of cellcentric is a strategic move by Daimler Truck AG and the Volvo Group to accelerate the development, production, and commercialisation of hydrogen fuel cell systems. By pooling their expertise and resources, the joint venture aims to lead the transition to zero-emission transport solutions. Hydrogen fuel cells offer a practical and sustainable alternative for long-haul transport, addressing the limitations of battery-electric solutions in terms of weight and range.

Shared Investment, Competitive Edge

The development of hydrogen fuel cell technology and infrastructure requires significant investment. Through cellcentric, Daimler Truck AG and the Volvo Group share the financial burden and risks associated with research, development, and production. This collaboration leverages their combined knowledge and innovation capabilities, positioning them at the forefront of the hydrogen fuel cell market.

cellcentric’s efforts are not limited to developing fuel cell systems but also include establishing a robust hydrogen infrastructure to support widespread adoption. With increasing support from governments and regulatory bodies worldwide, hydrogen is becoming a key component of climate strategies. Therefore, the company aims to align with these policies and meet market demand as regulatory frameworks evolve.

The fuel cell maker represents a strategic initiative to drive the future of sustainable transportation. By advancing hydrogen fuel cell technology and creating a comprehensive ecosystem, the joint venture is set to play a pivotal role in reducing carbon emissions and enhancing the efficiency of heavy-duty transport. With large-scale production on the horizon, it is poised to lead the charge in the hydrogen fuel cell market, contributing significantly to global sustainability goals.

Also Read: