Brakes India, a leading braking systems manufacturer, is on a strategic path to double its sales by FY27 and increase exports from 20% in FY24 to over 50% by FY29. While the past year saw challenges in commercial vehicle demand and European exports, the company remains optimistic about renewed growth from FY26, driven by new business programmes and higher-value components per vehicle.

To achieve its ambitious targets, the company has expanded its global footprint, enhancing its ability to secure international business. With long product validation and development cycles, the company acknowledges that timelines may shift but remains confident in its progress.

Expands Global Reach, Strengthens Engineering Capabilities

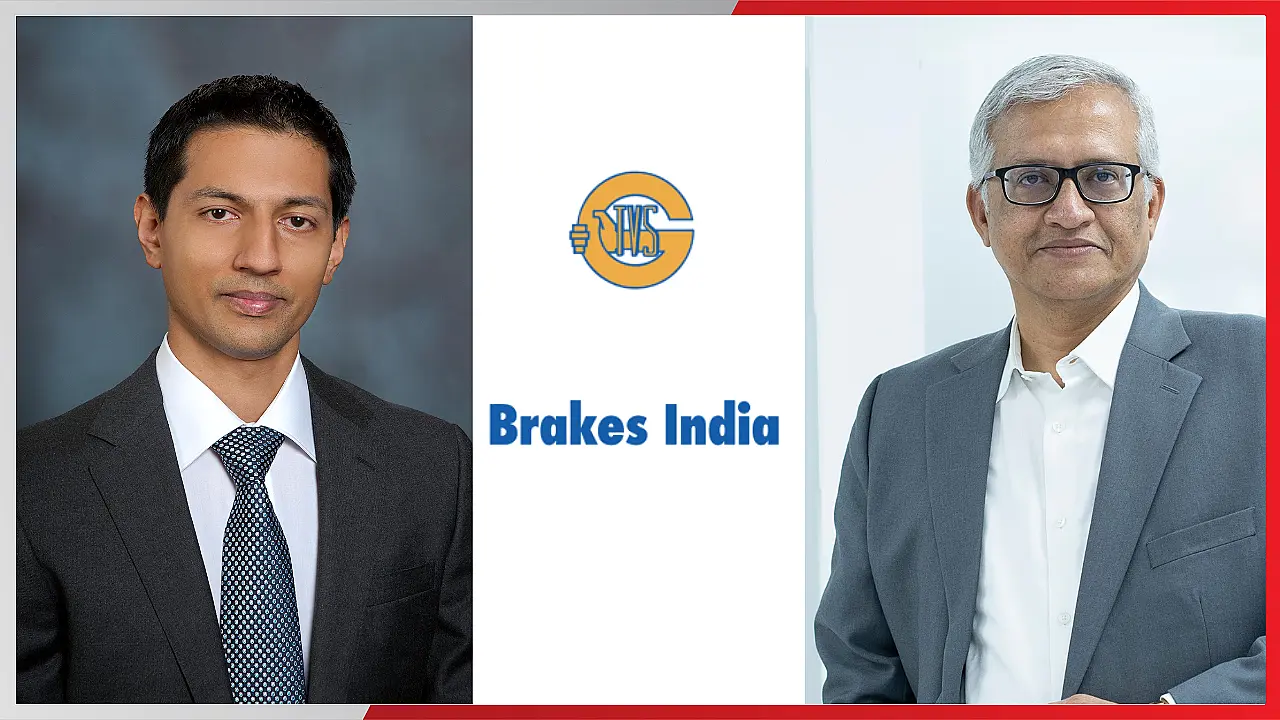

Speaking to Mobility Outlook, Sriram Viji, Managing Director, Brakes India, said, the company has strategically expanded its presence with offices in Germany, Japan, and Korea to strengthen global partnerships and drive exports. While Germany serves as a key market hub, the Japan and Korea offices play a dual role—supporting local OEM collaborations for the Indian market and facilitating joint engineering efforts with R&D teams abroad. These offices enable seamless coordination with multinational automakers, ensuring alignment in product development and market-specific requirements.

The company is also making inroads into North America, though the strategy is still evolving. With vehicles in this market being larger and heavier, Brakes India is fine-tuning its product offerings to meet regional demands. One such product is the 22.5-inch Monoblock calliper, designed for high-power applications, particularly in the trailer segment. Successfully tested and cleared for regulatory compliance in North America and Europe, the calliper is now being actively marketed for both OE and aftermarket applications.

According to Viji, the key driver of growth is the increasing focus on R&D, with investments rising by 15% over the past three years. This has led to advancements in pneumatic braking systems for commercial vehicles, which are already gaining traction with major OEMs. The company is also making strides in software and electronic braking solutions, particularly in mechatronic products like motor-on-drum brakes and motor-on-calliper systems. These innovations enhance passenger safety and provide premium features at a lower cost. Additionally, Brakes India is targeting high-performance electric and internal combustion vehicles with its opposed-piston callipers.

Export Growth, Green Innovation

Viji mentioned that currently exports are largely driven by the foundry division, supplying components to global manufacturers. This segment remains a key growth driver, with steady demand and strong traction in international markets. Meanwhile, the company is making strides in the braking sector, securing technical qualifications for global supply. While major orders are yet to be finalised, ongoing discussions and RFQs signal promising opportunities ahead.

The company’s pioneering work in green castings, initially developed for Volvo, has now extended to multiple export customers, particularly in Europe. With growing ESG commitments from global manufacturers, green castings have become a sought-after solution. While not yet implemented across 100% of production, the company has dedicated significant capacity to this initiative. Nearly 70% of its power is sourced from renewable energy, he mentioned.

Investment plans remain robust, with an annual capital expenditure of INR 250-300 crore. This includes ongoing capacity expansions, with new projects already in the pipeline. As demand grows, the company is prepared to scale up investments further, ensuring it stays ahead in the evolving global market, he added.

Slew Of Innovative Products

Talking on the innovative products, K Vasudevan, President and Head of the Light Vehicle Business, Brakes India, responsible for the products for the vehicles up to 3.5 tonne GVW, said, the company is revolutionising braking solutions with its motor-on-drum brake technology, catering to the evolving demands of modern vehicles, including those equipped with ADAS.

Traditionally, Indian vehicles have used drum brakes on the rear and callipers on the front, with parking brakes operated by a manual cable system. However, as automation advances, the need for electronically controlled parking brakes has grown, he pointed out.

Instead of adopting the motor-on-calliper system common in Western markets—which would require shifting from drum brakes to callipers—Brakes India saw an opportunity to electrify drum brakes. The company has been actively developing this motor-on-drum brake system, which is now nearing mass production. This innovation allows OEMs to retain drum brakes while integrating electronic activation via a simple cabin switch, freeing up space in the front compartment and enabling sensor-based control.

Interestingly, while drum brakes were once declining in global markets, Euro 7 emission norms have revived interest in them. Unlike callipers, which release emissions into the air, drum brakes contain brake dust within the drum, making them a cleaner alternative. This shift presents Brakes India with significant export opportunities, particularly in Europe, alongside catering to domestic demand, Vasudevan said.

Opposed Piston Calliper - A Game-Changer For Performance, Efficiency

Brakes India is developing Opposed Piston Calliper (OPC) technology, a significant advancement over conventional sliding callipers in passenger vehicles. Unlike traditional disc brakes, where a single-piston mechanism applies friction on one side while the housing reacts on the other, OPC features pistons on both sides, ensuring uniform braking force and eliminating taper wear, Vasudevan explained.

A major drawback of sliding callipers is the residual drag—where friction lingers even after releasing the brake, negatively impacting fuel efficiency, emissions, and regenerative braking in EVs. While innovations like the ultra-low drag calliper have reduced drag, they do not eliminate it entirely, he said. OPC, however, achieves near-zero drag, as there is no sliding component—only friction-generated contact remains.

This technology enhances straight-line braking performance, improves rigidity, and significantly reduces energy loss—a crucial benefit for electric vehicles and high-performance applications. “Beyond functionality, the red-painted callipers serve as a visual statement, aligning with the industry’s shift toward aspirational aesthetics,” added Viji.

Motor-On-Calliper

According to Vasudevan, Brakes India is advancing next-generation braking solutions with innovations such as motor-on-calliper and motor-on-actuator technologies, alongside its strategic joint venture with ADVICS to localise advanced braking systems in India.

Motor-on-Caliper is originally developed under a license from ZF. With the expiry of its license, Brakes India has transitioned to in-house development, enabling greater flexibility in providing solutions to multiple OEMs. Already supplied to Fiat Jeep and Mahindra’s XUV700, this system replaces conventional cable-operated parking brakes with electronic actuation, improving driver convenience and safety, he mentioned.

Motor-on-Actuator

With vehicle electrification reducing vacuum sources, traditional vacuum boosters are becoming obsolete. The alternative—vacuum pumps—adds cost and energy consumption. Brakes India is developing an electric booster (E-Booster) alternative, in collaboration with an engineering partner. This motor-on-actuator concept, once fully developed, will eliminate the need for a vacuum pump, offering an efficient electrified braking solution for modern vehicles.

With a strong focus on innovation, global expansion, and next-gen braking solutions, Brakes India is accelerating its drive for sustainable growth while redefining braking technology for the evolving automotive landscape.

Also Read:

Brakes India Commences PAN India Customer Engagement Programme