With automation increasingly becoming top priority for manufacturers, Karsten Mueller believes it is as important to boost efficiency and quality.

This is because, continues the Executive Vice President, Manufacturing and Quality of Bosch India, higher quality levels also come with safe automation.

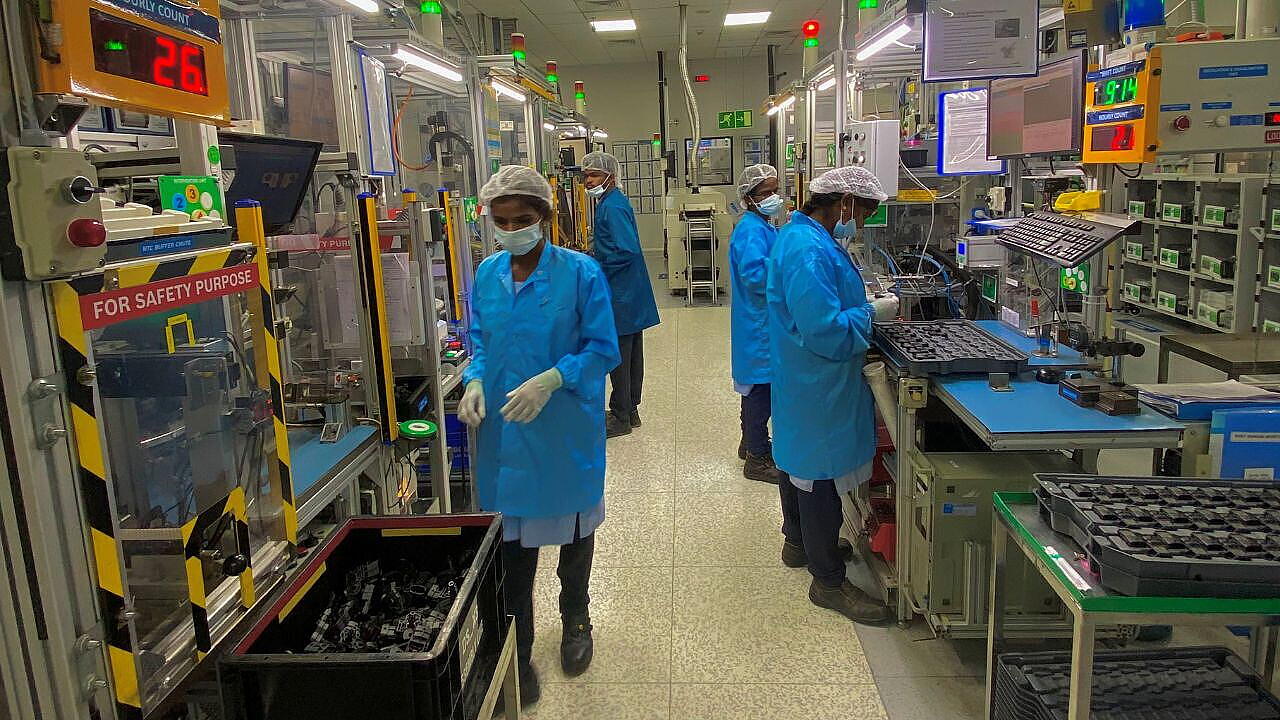

While the German ancillary supplier is no exception to this global trend, the interesting part about India is that operations are both manual and automated. Mueller is more than confident that the country will have attained significant levels of automation over the next decade.

Localisation Mantra

As he puts it, there are two angles to Bosch’s localisation strategy for India. One, it is obviously keen to reach very high levels across its 16 manufacturing sites. Right now, geopolitical tensions and the pandemic-induced disruptions have prompted the automotive industry to look for new solutions. These will get a big boost thanks to the Centre’s PLI scheme in enhancing technology.

“We are participating here (in the PLI scheme) and leveraging it to increase our localisation footprint. Customers will benefit and we can be much faster on reaction time. In many cases, we will also be able to meet price points/expectations of customers better with a local footprint, but not in all the cases,” explains Mueller.

Two, the huge transformation from combustion engines to newer technologies has compelled Bosch to “sensitively look into” what and where to invest in. “We are striving for early localisation in advanced technologies and focusing on technological competencies. This is in terms of what kinds of competencies are required from the product's perspective,” he says.

Digital is “always the same” and it is hence important to get the “fundamentals right” first. And if this really takes off in fuel cells or electrification, “I think we have all the products in the portfolio,” and the key, therefore, is to strive for “early localisation of these topics.”

The stronger the localised supply chain network is, the more it becomes decentralised. In the process, it can react a lot faster from a supply chain/throughput timeline.

Mueller, however, believes Bosch must improve on coping with fluctuations. “We have to work much closer with our customers and suppliers to get a deeper understanding of lean manufacturing and master fluctuations in a different way,” he elaborates.

There are some activities “we are working towards” and the goal is to improve global performance levels of value chains. There is “good openness and willingness” to collaborate in these fields as far as the automotive space is concerned.

While developing solutions for manufacturing and logistics, the challenge is to maintain sustainable operations. Bosch is addressing these issues with prognostics and predictive analysis which will help predict or reduce the failure rate. This is again linked to connectivity, says Mueller.

For instance, the company conducts analytics on the temperature and vibration of spindles through sensors in machining centres. It monitors real-time to detect failures before they occur.

“If the temperature of the spindle is going up, it gives an early indication that some dimensions on the part will fail. These are the kind of analytics we have implemented into our machines; we can react on deviations of the part before they are delivered to customers,” he adds.

According to Mueller, the maintenance departments at the plants are now working differently. Machining areas are equipped with dashboards that give an insight into machine parameters and if they are still standard or not. If they are not, “we can react earlier” and plan much better.

For example, he continues, a spindle change takes one or two shifts. “If you can do this in a planned manner as opposed to an emergency situation, it is much better. You are not in a hurry and can be well prepared to do it,” signs off Mueller.

Also Read:

Bosch Eyes Larger Role For India In Supply Chain

Bosch India Opens Spark.NXT Campus To Meet Future Business Expectations

Bosch India Crosses Ten Million Production Mark For Locally Produced ABS, ESP Units