A positive side-effect of the COVID-19 pandemic for air travellers will be the move towards a safer in-cabin environment using touchless devices inside commercial aircraft.

The attendant increase in cabin hygiene will further aid in adopting air travel with passengers demanding greater access to touchless services on board passenger aircraft. The changes to air travel will be on a similar level to that which took place nearly two decades ago, after the 9/11 attacks in 2001, which led to the introduction of enhanced Transportation Security Administration (TSA) security measures at airports and ballistic-resistant cockpit doors in aircraft.

Digital Solutions

Touchless will be the new normal in aircraft cabins and lavatories, and this transition is likely to be completed on all commercial aircraft by the end of the decade. In-flight entertainment (IFE) served on personal electronics devices (PED) has been gaining traction as a new way of delivering passengers services while reducing physical interaction either with physical devices on the aircraft or with cabin crew. It will also allow airlines to merge their retail offerings seamlessly with in-flight services such as food and beverages. Airlines will also gain higher revenue from retail platforms and advertisement providers due to moving information and basic services into a WiFi-based inflight service.

In June last year, Collins Aerospace, a Raytheon Technologies business, unveiled its new Electronic Cabin Bag (eCB) solution, which aims to enhance passenger experience and reduce cabin touchpoints. It allows passengers to use their PEDs for inflight shopping and service requests, eliminating the need for passengers to touch high-traffic call buttons. It also provides them with access to a real-time onboard inventory of food, beverage, and inflight shopping at any stage of the flight. The cabin crew can benefit from digitising documents and automating inflight processes and inflight inventory tasks.

“eCB gives airlines a boost in efficiency and ancillary revenue while simultaneously helping their passengers and crew feel confident in returning to travel,” said Clotilde Enel-Rehel, General Manager, Commercial Aviation & Network Services, Collins Aerospace.

The data and analytics generated by eCB will also enable airlines to make informed decisions to support their strategic and tactical planning better. The digitisation of documents will also aid in airlines’ efforts to reduce their CO2 footprint due to the weight savings and logistics associated with print media.

The transition towards open platforms will be the key accelerator for digitalisation, and the digital transformation and Lufthansa Systems has been one of the first companies to make the transition towards an open platform for its Inflight Entertainment solution BoardConnect. It provides a unique architecture that can easily be adapted towards installing a simple wireless entertainment system offering traditional audio and video on demand (AVOD) content or grown into a revenue platform with inflight retail and programmatic advertisement.

Touch-free Touchpoints

Touchless activation is not a new technology and has been available since the late 80s when touchless faucets appeared at airports and hotels. The technology used is fairly simple and consists of an infrared proximity sensor, which detects a nearby object and then enables water flow. However, this technology only appeared on aircraft much later due to the challenges in adapting this technology to meet very stringent aviation safety and durability requirements.

Many air travellers will attest that the lavatory is an area that is avoided unless absolutely required on short-haul flights and used as less as possible on long-haul flights due to the need to operate faucets, flush buttons and waste lids by hand. Efforts are underway to modify these into touchless faucets, touchless or foot actuated waste flaps and touchless flush buttons. The installation of touchless faucets was an effort to reduce water wastage and cut transmission of microbes and viruses and is available on many commercial jetliners today, including the Boeing 787 and Airbus A350.

Companies such as Safran Passenger Solutions already offer kits for the A350 and are developing kits for the Airbus A330, A320, A220 and Boeing B737. These will also be offered as line fit (installed on new aircraft) and retrofit solutions (installed on older aircraft). Safran Cabin, a pioneer in touchless waste flap technology, has delivered the first hands-free waste flap for aircraft applications. It offers an intuitive user interface, robust design, and quiet operation that provides passengers and crew with an easy, stress-free, hygienic lavatory experience and hands-free solution to waste disposal.

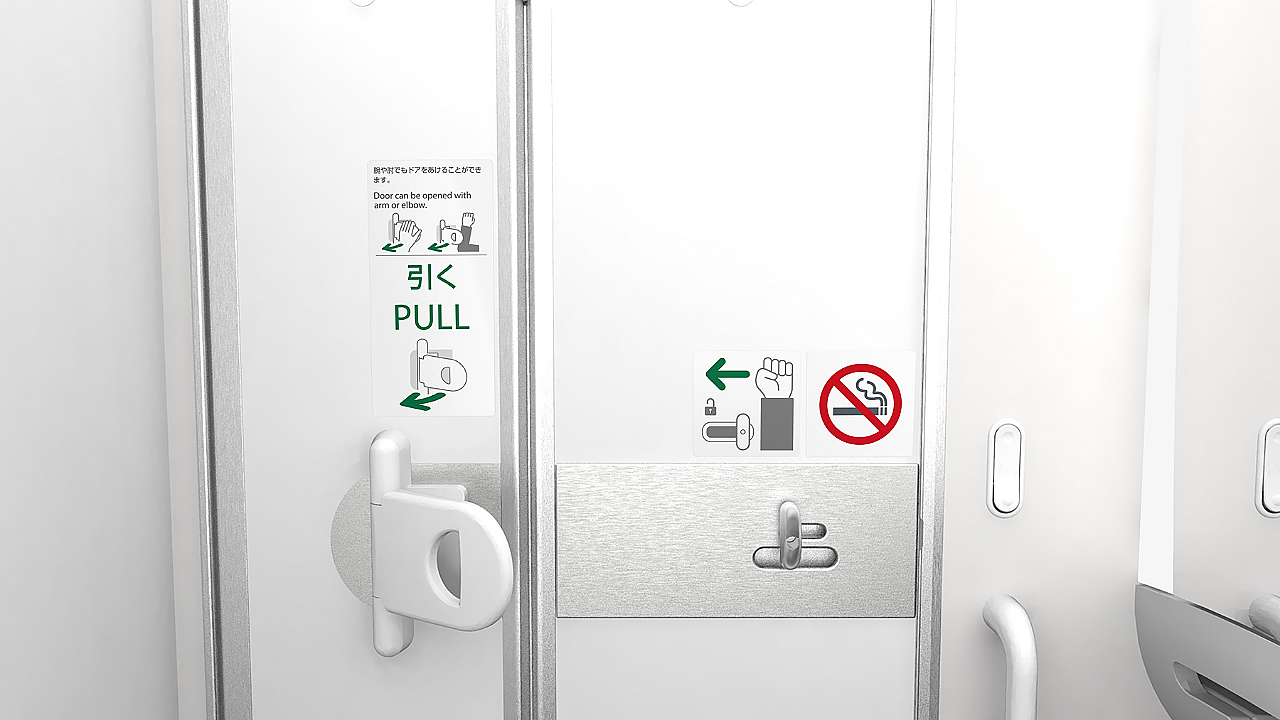

In September last year, Jamco Corporation’s hands-free lavatory door system was the first product worldwide to begin demonstration flights with an airline. The new hands-free lavatory door began testing at Tokyo Haneda Airport in August 2021 on an aircraft belonging to Japan’s All Nippon Airways (ANA). ANA was not only the developmental partner for the hands-free lavatory door but is also expected to be the first operator of this device. According to the Jamco, the new, hands-free lavatory lock knob and the door handle were well-received by most passengers.

Jamco and ANA worked together to develop the innovative door latch system, allowing passengers to open the door using their forearm or elbow. The new system can be installed overnight in existing lavatories without major modification, and the hands-free lavatory lock knob and door handle are low-cost items that won’t burden airline operational budgets. The hands-free lavatory was to be installed on 11 Boeing 787-8 aircraft, two Boeing 787-9 aircraft, and eight Boeing 777-200s belonging to ANA. Jamco also supplies touch-less flush switches for all B787 aircraft lavatories as standard equipment. The Japanese firm produces roughly 50% of the world market share of twin-aisle aircraft lavatories and is the sole original equipment lavatory and galley supplier for the Boeing 747, 767, 777 and 787.

Despite efforts to go touchless, an aircraft cabin features armrests, surfaces, trays, and knobs that must be disinfected. Sanitiser solutions are traditionally used for this; however, Lufthansa Technik is developing a sanitiser solution that can be applied using an electric spray method. According to Lufthansa Technik, applying its TiTANO sanitiser solution reduces the survival rate of bacteria and viruses to below 90 % within five minutes, and the surface is germ-free within 24 hours. The protection will last for a year. The electric spray method will also lead to a substantial reduction in time compared to the traditional way of wiping down surfaces.