Modern commercial jetliners feature distinctive upturned wingtip extensions, and these graceful looking aerodynamic devices have delivered significant fuel efficiency gains for their airline operators. These winglets are now fitted on nearly every new civil jetliner that is produced.

Commercial jetliner airframers are obsessed with reducing fuel consumption and invest heavily in R&D to deliver on these promises to their airline customers, who often operate on razor-thin margins. Fuel costs amount to nearly one-third of an airline’s overall expenses, and the efficiency benefits of modern winglets on commercial jetliners have benefited airlines enormously.

Airbus customers operating A320 family jetliners fitted with the company’s fuel-saving wing tip devices named ‘Sharklet’ have been enthusiastic about their benefits regarding reduced fuel-burn per aircraft and increased range. Sharklets reduce aerodynamic drag by decreasing the spiral-shaped vortices that form at the end of wings during flight.

Efficient winglet

Airbus’ Sharklet appeared in Indian skies a decade ago, when IndiGo and Go Air (now Go First) became the first Indian carriers to take delivery of Sharklet equipped A320ceos in January 2013. Following this delivery, both Indian carriers took delivery of all their A320 Family jetliners fitted with Sharklets.

A320 family jetliners (both CEO and neo) with Sharklets have delivered fuel burn savings of up to 4%; it also reduced annual CO2 emissions per aircraft by approximately 900 tonne during the long haul.

The 2.4 m tall Sharklets have also enhanced aircraft performance, allowing operators to extend mission range by up to 185 km or increase the aircraft’s payload capacity by 450 kg on standard operating conditions.

IndiGo, Go First, Air Asia India, Vistara and Air India have benefited from Sharklets as they require reduced take-off thrust for the same take-off weight, resulting in lower engine maintenance costs (by approximately 2%) due to longer on-wing time for the engine (removing an aircraft engine from the wing for maintenance is an expensive affair). In addition, the enhanced aerodynamic performance due to the winglets also resulted in better climb performance, allowing the aircraft to attain a higher initial cruise altitude, thereby reducing fuel consumption.

Standing tall

Airbus fitted the 2.4 metre-tall Sharklet as standard on all A319neo, A320neo and A321neo aircraft whose wings were structurally reinforced during production to allow its integration. Older A320ceos, which received the wingtips as part of the Sharklet Wingtip Production Retrofit or In-Service Retrofit (ISR), could fly for an additional 36,000 flight hours along with obtaining an aircraft service limit extension of 10 years. These retrofits allowed operators to increase the efficiency of their older A320 aircraft, thereby enhancing their aftermarket value.

Airbus has offered Sharklets as production retrofits to A319, A320 and A321 operators since February 2013, whereas the In-Service Retrofits (available only on A319 and A320) commenced in 2015. Sharklet originally became available as an option for all new-build A320 family customers starting December 2012. New build A320neo jetliners received a modified structure (centre wing box and wing), allowing integration of Sharklets and were delivered with the required updates to its flight computer system.

A new standard

The Sharklets replaced the distinctive smaller, triangular-shaped wingtip devices seen on older A320 families and introduced LED navigation and strobe lights, replacing older lighting technology. Airbus was a pioneer to use wingtip devices on commercial jetliners, with the distinctive arrow-shaped vertical wingtip fences first appearing on the A300 and A310 jetliners in the eighties.

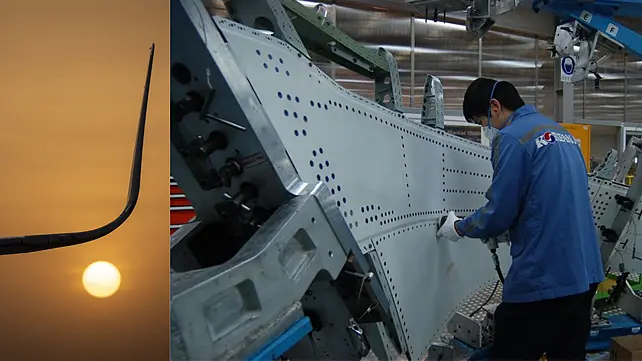

The A320 Sharklet wingtip is designed as a single piece with Carbon Fibre Reinforced Polymer (CFRP) laminated spars and panels with honeycomb cores. Airbus commenced the development of the new wingtip devices in October 2009. Korean Air’s Aerospace Division manufactures all Sharklets for the A320 Family as the sole supplier in Busan, South Korea. The company received the contract from Airbus for Sharklet manufacture in 2010 and started series production in July 2012.