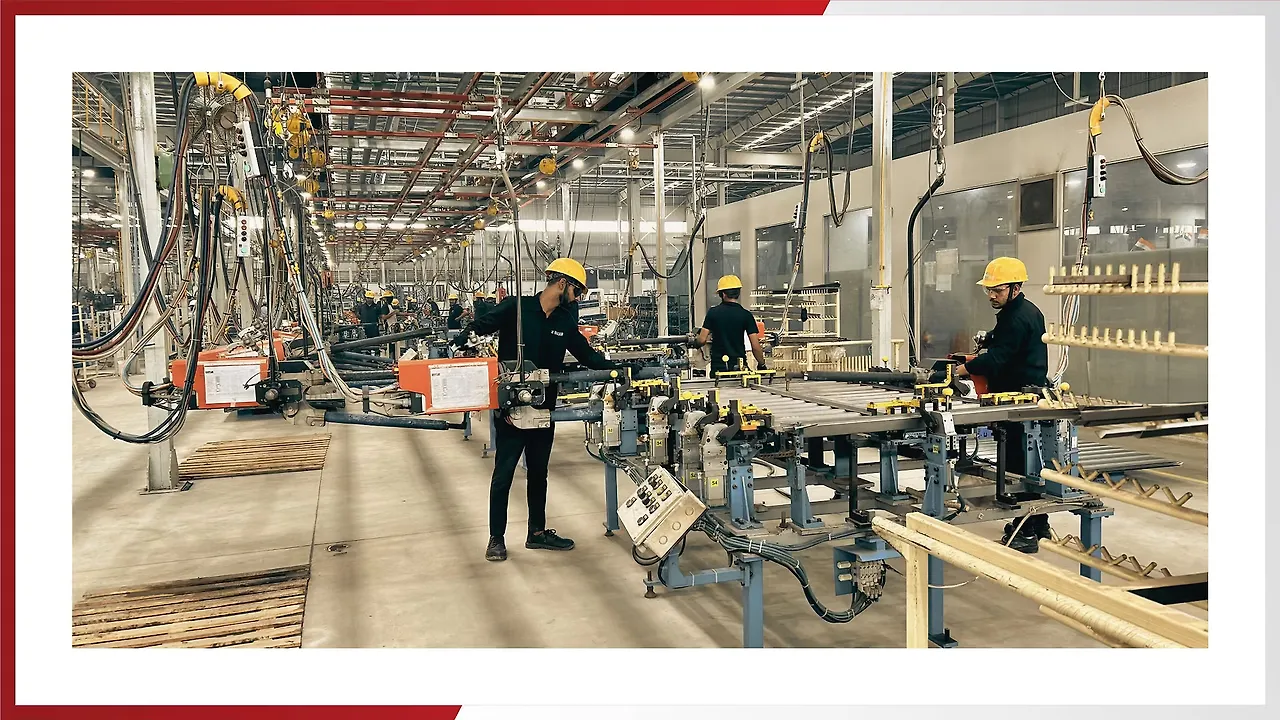

Nestled in Palwal, at an hour's distance from the heart of Delhi, sits the 500,000 sq ft EV manufacturing unit of Euler Motors. As the successful push for increasing E3Ws for mid to last-mile deliveries is rising, Euler has a compelling recipe in its hands. Flexible manufacturing abilities allow the brand to adapt quickly to shifting market priorities and even quicker regulatory conditions. We got a chance to walk through the plant to experience the seamless assembly of the HiLoad EV and a quick chat with Saurav Kumar, CEO and Co-Founder of Euler Motors.

How did you decide on the aggressive design and the choice of white for the vehicles?

In the automotive sector, speed to market is crucial, but safety is paramount. When we launched Euler in 2018, we moved quickly, deploying our first pilot vehicle within six months. We built and tested the vehicle ourselves, making do with available components. Over the first two years, we produced around 200-250 vehicles, running millions of kilometres to understand the Indian market's needs.

During this period, we realised that the market viewed electric vehicles (EVs) as inferior to internal combustion engine (ICE) vehicles, primarily because EVs were seen as lacking in power and presence. To counter this perception, we needed a design that projected strength and reliability, which could be quiet yet powerful—much like the Royal Bengal Tiger. The tiger, which is not the fastest but can accelerate rapidly when needed, inspired our design. This aggressive design, coupled with the choice of white, helps convey the message that our vehicles are powerful and dependable.

Can you elaborate on the processes at Euler Motors and how they contribute to the product's performance?

At Euler Motors, we are deeply involved in every aspect of vehicle development, from design to testing. One of our key innovations is the vehicle's torque, which reaches 88 Nm, comparable to what you find in four-wheelers. This allows our vehicles to handle heavy loads (almost 688 kg of payload) and steep inclines with ease. We've optimised efficiency over time, ensuring that our vehicles offer the best performance in basement parking or on a highway.

We also put a lot of emphasis on the batteries. Safety is critical, which is why we don't allow phones in our battery production areas due to the risk of sparks that could cause a fire. Additionally, our batteries undergo rigorous testing, including full submersion tests, to ensure they can withstand extreme conditions like floods. This meticulous attention to detail ensures our vehicles are reliable, even in the harshest environments. When it comes to chemistries, we work both with LFP and NMC. This gives us the ability to adapt to either as per demands.

How does Euler Motors manage its supply chain and the challenge of battery chemistry?

Managing the supply chain is a critical aspect of our operations. We support multiple battery chemistries, which allows us to be flexible in case of supply chain disruptions. For example, if a specific chemistry or component becomes unavailable due to geopolitical issues, we can quickly switch to an alternative. This adaptability is crucial, especially in an industry where customer preferences and technology are constantly evolving.

We also design and manufacture many components in-house, including battery packs, cooling systems, and electronic controls. This approach not only helps us maintain quality control but also allows us to respond to customer feedback and make necessary adjustments quickly.

Can you share some insights into your pilot tests and how they influenced the final product?

Our pilot tests were extensive. For the first three years, we focused on understanding our vehicles' optimal payload capacity and range. We realised early on that our customers needed a vehicle that could reliably cover 120-140 kilometres on a single charge. While certification tests might show higher ranges, we focused on real-world conditions to ensure our vehicles meet the daily demands of our customers.

These tests also helped us refine other aspects of the vehicle, such as the powertrain, which we improved by about 9-10% in efficiency. By constantly analysing data from these tests, we've been able to optimise our vehicles to perform exceptionally well under typical usage scenarios, ensuring long-term reliability and value retention.

What are your thoughts on the regulatory environment for EVs in India, and how does it impact your operations?

The regulatory environment in India has improved significantly over the last decade, with strong support for EVs. However, there is still room for improvement, particularly in the consistency and duration of subsidies. Longer-term policies help companies like ours plan more effectively. Despite these challenges, the growth in the EV ecosystem in India has been impressive, and with continued support, the country can become a major player in the global EV market.

Which are your key markets in India, and how are you planning to expand?

Our key markets include Delhi, Bangalore, Chennai, Hyderabad, Pune, Mumbai, and Kolkata, among others. We're also expanding into Tier-2 cities like Jaipur, Indore, and Patna, where we're seeing increasing demand. Our goal is to double our presence from 20 to 40 cities this year. We aim to ramp up production to meet this demand, with a capacity to produce up to 36,000 vehicles annually running through three shifts.

What is Euler Motors' priority moving forward? How do you manage to keep track of all these activities?

Our top priority is ensuring that our drivers have the best possible experience with our vehicles. This means focusing on post-purchase support, ensuring that the vehicles are reliable and efficient. Expanding our presence in Tier-2 and Tier-3 cities is also a key focus, as we want to make our vehicles accessible to a broader customer base across India. Finally, scaling up our manufacturing capacity to meet growing demand is crucial, and we're working hard to achieve this.

'I'm passionate about building and engineering, so I enjoy being hands-on with many aspects of the business. I'm fortunate to have a brilliant team that helps manage the day-to-day operations, allowing us to stay on top of everything from manufacturing to customer support.' This collaborative approach ensures that we can maintain the quality and performance that our customers expect from us.

Also Read

Sneak Peek In Euler Motors State-of-the-Art EV Manufacturing Facility In Haryana