As Managing Director of Altair India, Vishwanath Rao drives and evolves Altair’s business and operations across South Asia & GCC countries, while nurturing a strong leadership team to drive its growth. He manages regional strategy, client relationship, technical and sales effectiveness to ensure Altair’s exceptional growth. Since joining Altair in 1999, he has held several senior leadership roles, including Director of Sales, South Asia & GCC. He has played an instrumental role in developing strategies and solutions for various industry verticals in simulation-driven design.

What are the fundamental driving forces for software proliferation in designing and developing vehicles?

The modern consumer and his fast-changing lifestyle, design awareness, and quest for superior product performance demand rapid design exploration and validation. Today’s products are feature-rich with integrated smart systems that need a smart development approach using high-end technology, materials, and manufacturing methods.

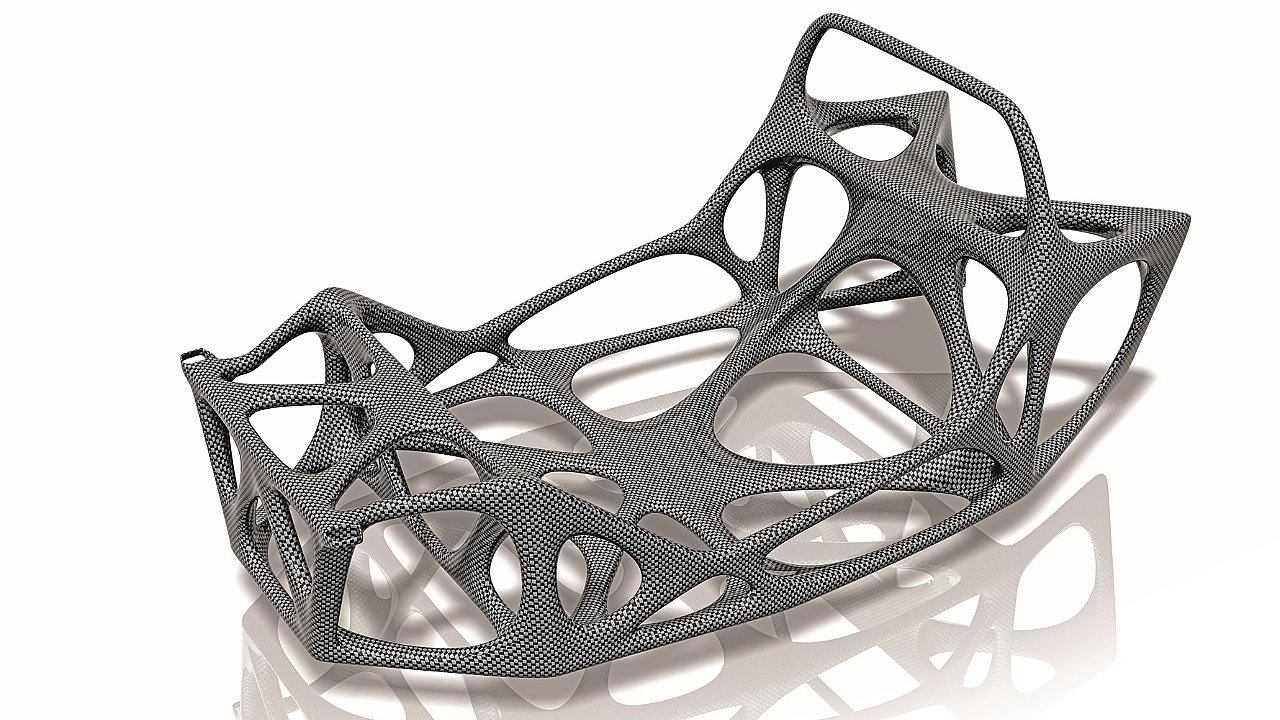

Though well recognised for the design and development of mobility systems, traditional physics-based simulation and testing is very manpower- and compute resource-intensive. Moreover, with increasing competition and reduced development timelines, there is a risk of limited physical validation, leading to recalls and brand erosion. The AI-augmented CAE can help designers use historical product performance data to build predictive ML models that rapidly validate designs.

What about the new mobility?

The new mobility systems must be smart to address the new consumer demands. Today’s technology can help port the predictive models on smart devices that can predict product performance and interact with the consumer.

What are the software requirements for new mobility?

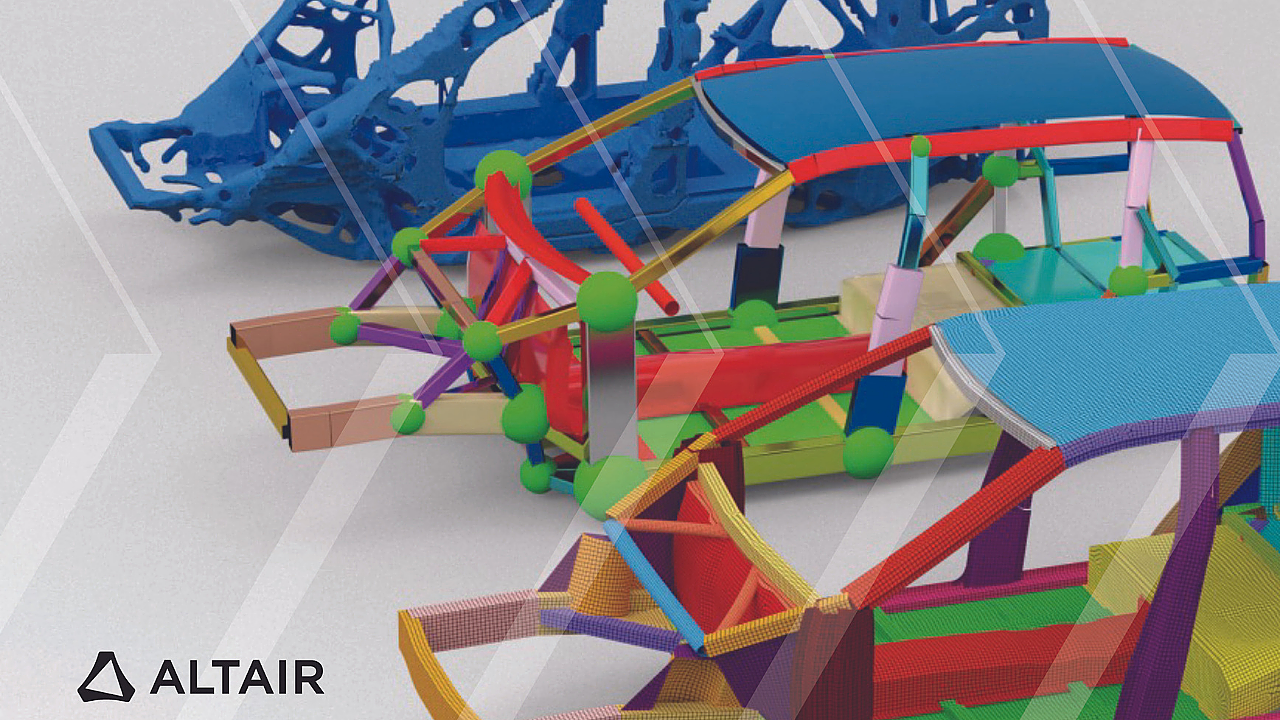

Today’s products are complex and integrated multi-disciplinary systems comprising many electronics, control and mechanical systems that must be designed in a collaborative environment and not developed in a silo. The software platform should provide tools and methods for developing a new architecture, connectivity, electric drivetrain development, battery and controls with embedded systems, edge orchestration, device management & data storage, aerodynamics and light weighting.

Our technologies accelerate the development of new mobility systems by providing all the technologies in a single framework with seamless interaction between multi-disciplines, using new technologies of Artificial Intelligence (AI) and Machine Learning (ML) in a smart integrated development platform.

Developing methods to tackle the evolving market demands like electrification, new user and driver behaviour such as shared and autonomous driving, implementing global best practices and adherence to the process through automation make the simulation even more attractive to OEMs in bringing down cost, reducing development time.

With Indian automotive component manufacturers getting new opportunities due to geopolitical issues despite disruption induced by COVID, what kind of opportunities do you see, and how do you plan to cater to them?

COVID has brought with it unprecedented crisis and needs. Virtual product development has assumed significance like never before because of this. Test tracks and physical testing equipment take much time to be ready; they are also expensive real estate, require a sizable workforce to operate and maintain.

Software for virtual product development does away with such expensive logistics and infrastructure. Remote training and support make simulation software more user friendly. Innovative business models like Altair’s make software solutions even more cost-competitive.

Can you elaborate?

Altair’s solutions encourage cross-functional product development teams, with members from OEMs, Tier I and Tier II suppliers and other stakeholders and bring them together to develop multiphysics and multi-disciplinary models with high fidelity to simulate and replicate the physical behaviour of the vehicle. This collaboration reduces and eliminates the costs generated by late design changes, supply chain and physical prototype. AI and ML, coupled with high-performance computing, are being used to make exponential improvements in the prediction times of Altair’s simulation frameworks.

What kind of value addition does Altair give to its customers?

Our simulation technologies span various levels of model fidelity ranging from 0D to 3D. These are applied at various stages of development, based on the need for turnaround time and accuracy of simulation results.

We offer one of the most comprehensive range of simulation tools under one single licensing system to address various types of physics such as Structures, Computational Fluid Dynamics, Electromagnetics, Systems Simulation, EDA and Bulk Materials. All of this can be applied independently or in a multiphysics environment to solve real engineering problems.

Altair’s Knowledge Works Data Analytics platform further enhances these technologies by combining AI and ML to ramp up innovation.

With these technologies, we address critical OEM needs like electrification, packaging & performance, passenger safety & comfort, improved fuel efficiency & life, connectivity & autonomous driving, fleet monitoring and remote diagnostics.

What are Altair’s recent contributions to automotive, aviation, marine and railways?

We are a product development partner to the world’s largest OEMs and suppliers. Our work helps accelerate product development, enhance passenger safety and experience, while optimising vehicle fuel economy and durability. Our technologies are changing the way vehicles of all types are designed.

Simulation of product functions and design helps companies optimise durability, safety, efficiency, user experience and a host of other benefits. Moreover, it reduces the need for changes after real-life test results as that could be expensive, time-consuming and risky.

Altair has been offering innovative technologies for many decades. Some of the recent contributions are an integrated framework for vehicle concept architecture development, integrated AI/ML-based simulation workflows at the desktop and on the cloud, simulation for battery and motors and connectivity, integrated math and systems modelling using best of both 1D and 3D world, material model development tools and a rich library of close to 20,000 materials for use in the design and development process, etc.

Can you through some light on the software in product testing?

Simulation helps in many ways in the testing phase. One such example is that software can help simulate dynamic loads of real-life scenarios and predict stress or strain hot spots during simulation. This allows test engineers to identify the right locations, where strain gauge measuring devices can be planted on the vehicle during testing to accurately measure and calibrate the simulated design.

Our solutions for model-based firmware development of embedded systems and other products play a vital role in the product development lifecycle of our clients.

What are the new opportunities that Altair could identify globally and in India during the disruption caused by COVID?

Facilities to build diverse products, flexibility to work on low volume and high product mix are the need of the hour. In a remote Work from Home routine, it has become difficult for engineers to access software and compute resources to run the physics-based simulation for design validation. Our cloud-based software license platform helps engineers seamlessly connect and access the software and run large scale simulations on the cloud. This has allowed product companies to continue their design and development efforts with minimal or no disruption due to COVID.

What is the role of the India operations of Altair in developing solutions?

The Indian operation of Altair has software development and product consulting groups. Most of the software development and testing of the modelling and visualisation tools, and some modules of the physics solvers is done in India. Also, the product consulting team has worked on numerous niche customer projects providing solutions to various customers from automotive, aerospace and other industries.

Is the India centre specialising in any specific fields?

The India centre has been instrumental in collaborating with premier institutions for cutting-edge innovations, which are trailblazing for not just Altair’s operations but also the nation. For example, we tied up with IIT Madras to add the Indian Shakti processor to Altair Embed’s portfolio offering expansion. For more than 30 years, Altair Embed has been innovating simulation technology for optimising the design, processes of embedded systems such as motor control, Internet of Things (IoT) devices, and vision systems.

Our environment allows reliable systems to be built and validated through simulation or hardware-in-the-loop (HIL). Shakti is the country's first indigenous RISC-V processor and is the perfect candidate to take our ability to build such embedded firmware for interconnected devices a notch higher.

We are also sharing relevant skillsets with the Indian EV industry by collaborating with multiple partners like CII, ARAI, Startup India, and from the skill development support through MSMEs and SMEs apart from Altair COE's compassion for EV. Altair is mentoring and hand-holding several EV start-ups, and many successful EV start-up companies have adopted our solutions. We have dedicated this year’s Altair Start-up Challenge for EV start-ups, and we are currently mentoring close to 40 EV teams.

We are also seeing great interest to use AI and ML to accelerate innovation. Our Knowledge Works Data Analytics platform coupled with simulation offerings is turning out to be a game-changer. There is much emphasis on perceived quality and comfort with our technologies like NVH and Squeak and Rattle Director, which greatly enhance driver and passenger comfort. As mentioned earlier, electrification is driving demand for various technologies.