Amit Jain is the Executive Director & Group CTO of Uno Minda, joining the organisation in 2017. His significant contributions include establishing the CREAT (Centre for Research, Engineering, and Advanced Technologies), which focuses on developing advanced technology in mobility solutions.

Before his tenure at Uno Minda, Jain worked at Visteon Corporation, where he held the position of Country Head – Electronics and at Escorts Limited. His extensive career covers various aspects of the business, including business development, programme management, engineering and product development, vendor development, and manufacturing.

What megatrends do you follow, and how are you preparing the company to become OEMs' preferred systems supplier?

As Uno Minda, we envision a future defined by technological advancements that empower safer, smarter, and more sustainable mobility solutions. We actively decipher and integrate these trends into our product and solution roadmap, focusing on the PACE (Personalisation, Autonomous, Connected, and Electric) megatrends that are reshaping the automotive landscape.

Personalisation: Consumers are demanding a more customised driving experience. Uno Minda is prepared with advancements in lighting, seating, and in-vehicle technology, offering 'affordable luxury' to the future driver.

Advanced driver-assistance systems (ADAS): These systems will continue to evolve, incorporating features like automated emergency braking, lane departure warning, and adaptive cruise control. Cars equipped with AI, LiDAR, and advanced sensors are poised to revolutionise transportation, enhancing safety and efficiency while reducing accidents.

Connected:Integrating components with IoT will lead to real-time data collection, enabling condition-based monitoring and proactive maintenance. This will improve efficiency and reduce vehicle downtime. Vehicle-to-everything (V2X) communication technology allows vehicles to communicate with each other and with infrastructure, enabling features like collision avoidance and improved traffic management.

Electrification: EVs have gained traction owing to their eco-friendliness and efficiency. Advancements in battery technology, fast-charging infrastructure, and increased range are redefining the landscape of automobiles.

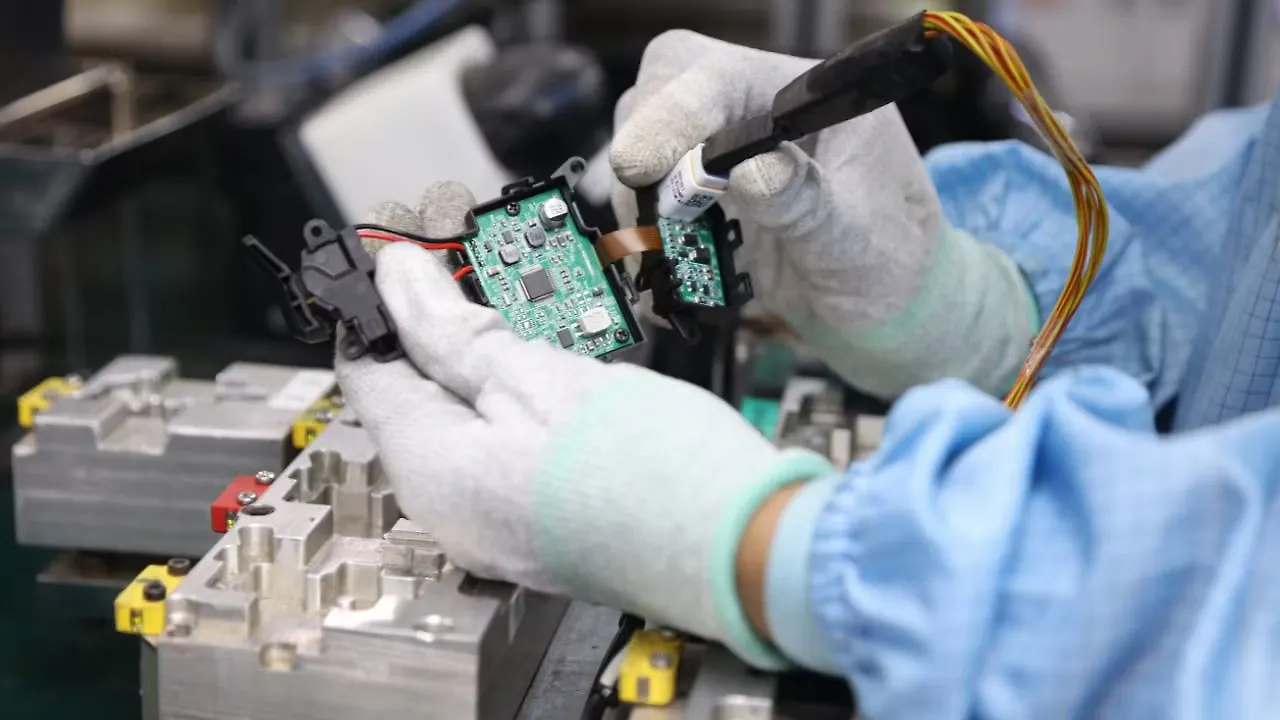

We offer a diverse product portfolio spanning these technological trends, including infotainment systems, interior and exterior lighting, climate-controlled seats, logo projectors, and wireless chargers tailored for personalisation, as pioneers in the Connected Car platform, accredited with India's first connected car platform. Uno Minda's parking systems, assistance features, and even intervention systems like lane departure warning and blind-spot detection, all powered by ultrasonic sensors and camera technology, make every drive safer and more confident. We have also built a formidable EV-specific components and systems portfolio manufactured in our recently commissioned greenfield EV plants.

How does Uno Minda, as a Tier-1 supplier, ensure product readiness even before OEMs consider specific features and technologies? Can you discuss the company's inherent potential and capabilities to support these requirements?

As a leading Tier-1 supplier, Uno Minda stays ahead of the curve for OEMs in two key ways: our robust R&D capabilities and unwavering commitment to innovation. CREAT, our centralised R&D powerhouse, drives our innovation engine. Here, a team of experts constantly explores emerging technologies and consumer trends. This allows us to anticipate the needs of future OEMs and develop solutions before they are even on the drawing board. For example, with the rise of electric vehicles, we proactively invested in power electronics and powertrains, positioning ourselves as partners for future EV demands.

Furthermore, our global network of R&D centres fosters collaboration and knowledge sharing. This ensures we have a finger on the pulse of advancements across different regions. By constantly pushing the boundaries and experimenting with new technologies, we can present cutting-edge solutions to OEMs, even sparking their imagination for features they may not have initially considered. Also, the focus on customer-centric innovation is paramount. The belief at Uno Minda is that the customer is supreme. We understand that OEMs need reliable partners who can not only deliver on current needs but also anticipate and fulfil future requirements. Through continuous innovation and a deep understanding of megatrends, Uno Minda is well-positioned to be the preferred Tier-1 supplier, providing cutting-edge solutions that shape the future of mobility.

What are the challenges you face in developing innovative solutions?

The biggest challenge we face is not creating innovative solutions itself. Uno Minda boasts a robust R&D infrastructure and a culture of continuous improvement. Our true challenge lies in offering the right technologies while balancing cost and localisation. We need to identify the technologies that will have a lasting impact and invest in them strategically while balancing cost-effectiveness and localisation of sub-components.

Besides, development cycles given by OEMs have also become more demanding and shorter while maintaining rigorous quality and safety standards.

Despite these challenges, we have adapted to the changing dynamics and are well-positioned to develop innovative solutions for their OEM customers. We can proactively develop solutions that meet and exceed OEM expectations by staying at the forefront of industry megatrends.

Uno Minda has been supplying several systems and components. Can you tell us about the adjacent areas you are looking at to enhance the content per vehicle? What are the sweet spots you have identified?

While Uno Minda is already a market leader in supplying many systems and components – from instrument clusters to infotainment systems – we strategically explore adjacent areas that seamlessly integrate with our core competencies. This ensures that we can offer unparalleled value to our customers. Our focus remains on areas where we can leverage our existing strengths. For instance, advancements in in-vehicle connectivity align perfectly with our expertise in telematics. This allows us to provide OEMs with comprehensive content delivery solutions. With a formidable 2W/3W EV-specific product portfolio, we are progressing towards building similar portfolios for 4W EVs.

ADAS offers multiple opportunities with a complex interplay of sensors, cameras, and software. Another emerging opportunity is infotainment systems, which are no longer just for infotainment but also various vehicle control and data displays. We are working on all these emerging technologies to maximise content per vehicle while reinforcing our position as a technological leader.

What are your contributions to the manufacturing operations to reduce cost per unit, productivity, rejections and digitalisation?

The Indian auto and auto component space is very competitive, requiring continuous cost reduction and productivity enhancement measures. We run several projects across the departments, identifying opportunities for increasing production and cost efficiency. Hence, we built a culture of productivity improvement across the organisation.

We have also focused on localisation as a cost-reduction measure by developing a local supplier base for raw materials and capital goods like machinery and equipment. At our material science department, we keep on evaluating alternative materials that facilitate light weighting, localisation, and/or cost reductions.

Some of our plants have the best productivity and efficiency in India and worldwide. Our global technology partners' sending their teams to understand our manufacturing process and systems at various times is testimony to our manufacturing prowess.

Our Information Technology team has been working on digitalising the manufacturing process and systems with real-time monitoring. This will also help with preventive maintenance and efficient workflows.

Can you update us on your R&D and Engineering centres? Are these centres also contributing to other Tier-1s or OEMs?

At Uno Minda, we have always been at the forefront of technology and innovation. We have been making continuous investments in R&D over the last few decades. We accelerated our effort by setting up a central R&D centre in 2017 and christened it as CREAT. The centre's objective was to make our existing product lines smarter and work on emerging technologies. CREAT is now present in Gurugram, Hosur and Chennai, starting with Pune. Besides CREAT, we also have more than 30 R&D and Engineering centres across the globe, including Germany, Spain and Taiwan.

We recently established two dedicated verticals within CREAT: the Global Centre for Embedded and Software Technologies (GCEST) and Advanced Engineering & Technologies. These dedicated verticals will strengthen our focus on cutting-edge technologies, including software development.

We have been rapidly expanding our team of engineers in R&D Centers, with more than 1,000 engineers. We are amongst the few organisations investing around 4% of their revenues into R&D. To date, Uno Minda has filed over 400 patents and 450 design registrations, showcasing the robustness of our local R&D capabilities.

Our R&D efforts have also been recognised by CII as among the top 50 innovative companies in the manufacturing sector for the second year in 2023. Uno Minda has also been honoured with the Intellectual Property Award 2023 in the Top Indian Company for Design category from the Ministry of Commerce and Industry.

Also Read: