The manufacturing industry is experiencing a profound transformation, driven by technological advancements, digital connectivity, and shifting global priorities. The pandemic acted as a catalyst, accelerating the adoption of smart manufacturing and automation, compelling industries to rethink operations, enhance resilience, and future-proof supply chains.

This shift has been further propelled by 'Make Here' policies across nations, fostering localized production, supply chain reinforcement, and industrial self-reliance. As manufacturers embrace Industry 4.0, the integration of AI, IoT, 5G, and cloud computing is redefining efficiency, scalability, and competitiveness.

Recognizing this transformation, Airtel Business, in collaboration with Zamun, has released a Whitepaper titled 'Wired to Win', offering deep insights into how digitalization is revolutionizing manufacturing. The report explores key innovations, challenges, and strategies that are empowering businesses to drive efficiency, enhance agility, and secure a competitive edge in the evolving industrial landscape.

Powering India's Manufacturing Growth With Smart Technologies

The 'Wired to Win' whitepaper explores the evolution of manufacturing through the adoption of wireless connectivity, cloud computing, and networking technologies. As India strives to elevate manufacturing’s GDP contribution from 13% to 25%, the ‘Make in India’ initiative has already fuelled exports, reaching $0.45 trillion with a 6% growth in FY23.

To sustain this momentum, manufacturers—both large-scale enterprises and SMEs—must embrace networked environments, leveraging AI, autonomous systems, and cloud computing, the Whitepaper proposed. The transition to intelligent, self-learning machines is a paradigm shift, enhancing efficiency, automation, and scalability. However, for these innovations to reach their full potential, businesses must invest in workforce upskilling in cloud technologies, AI, and data governance.

Additionally, defining clear KPIs and selecting the right technology stack are critical for success. With smart infrastructure, digital intelligence, and strategic investments, India’s manufacturing sector is on the brink of an unprecedented transformation, driving innovation, global competitiveness, and economic resilience, the Whitepaper observed.

TASK-ICAN: A Strategic Roadmap

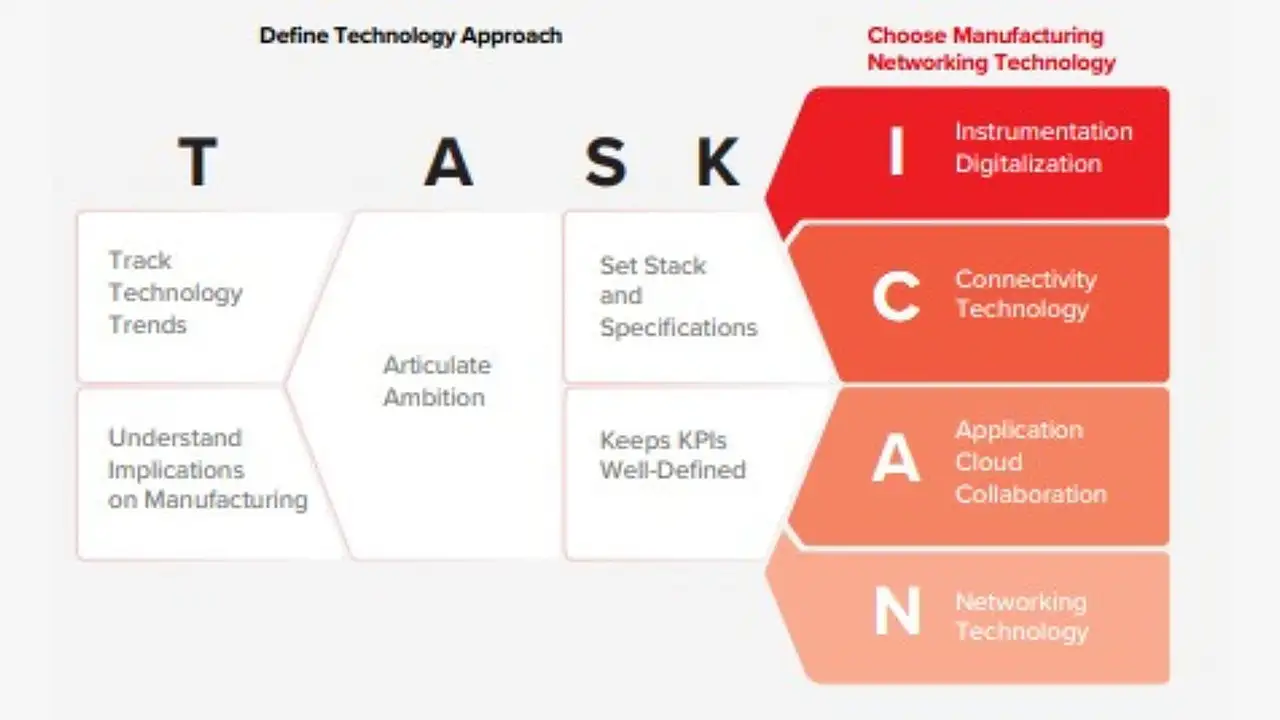

As India’s manufacturing sector undergoes rapid digital transformation, the Whitepaper introduces the TASK-ICAN approach, a structured framework to maximize returns on technology investments.

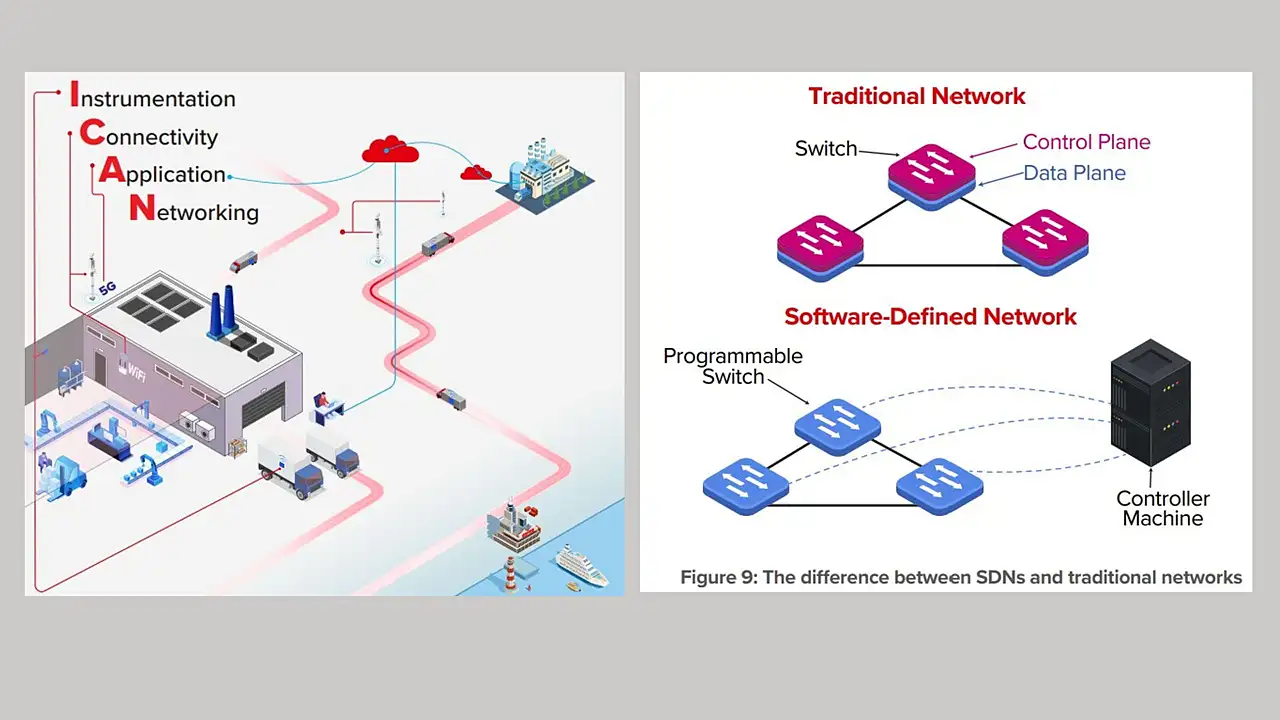

The strategy begins with TASK—Tracking technology trends, Articulating ambitions, Setting clear goals, and specifying the right technology stack. Once the foundation is laid, manufacturers must adopt ICAN—Instrumentation, Connectivity, Applications, and Networking Technologies—to align technology with business objectives, ensuring a holistic, efficiency-driven digital transformation.

According to the Whitepaper, the following five key trends reshape India’s manufacturing landscape:

- Geopolitical Shifts & Localization: The 'Make in India' and PLI (Production-Linked Incentive) schemes are driving domestic production, with the 'China +1' strategy positioning India as a global supply chain alternative.

- Sustainability & Digital Transformation: AI and IoT are optimizing operations while reducing carbon footprints, making sustainability a core focus for manufacturers.

- Accelerated Product Development: By 2026, lead times are expected to shrink by 30%, enhancing speed-to-market and competitiveness.

- Outcome-Based SLAs: Manufacturers are shifting towards performance-driven contracts, prioritizing measurable productivity and cost efficiency.

- Workforce & Skill Gaps: With 85-90 million skilled workers needed in advanced manufacturing by 2030, upskilling remains critical.

Advancing Toward Industry 4.0

India’s manufacturing sector is embracing Industry 4.0, where IT and OT integration enables smart, data-driven factories. AI, machine learning, predictive maintenance, and digital twins are revolutionizing decision-making, efficiency, and operational resilience. The rise of 3D printing and AI-powered predictive maintenance is further accelerating time-to-market and process optimization, solidifying India's position as a global manufacturing powerhouse.

Enabling The Future Of Smart Manufacturing

As manufacturing evolves into a hyper-connected and intelligent ecosystem, Airtel Business is playing a pivotal role in driving technological integration and digital transformation. With its expertise in instrumentation digitalization, the company enables seamless IoT integration, empowering manufacturers with real-time monitoring and precision control.

Advanced connectivity solutions, including 5G, provide high-speed, low-latency communication, ensuring optimized industrial automation and uninterrupted enterprise operations. Its cloud infrastructure and collaborative applications facilitate secure data management and cross-functional collaboration, while robust networking solutions offer a secure and scalable foundation for interconnected manufacturing systems. By bridging IT and OT, Airtel Business is empowering enterprises to transition toward Industry 4.0 and beyond.

The Rise Of Industry 5.0

As manufacturers move from automation-driven Industry 4.0 to the human-centric Industry 5.0, the integration of generative AI and advanced robotics is unlocking new efficiencies and innovations. However, this transition brings challenges, particularly in cybersecurity, data privacy, and legacy system integration. Enterprises must ensure technological maturity, moving beyond connected factories to autonomous systems, while aligning investments with long-term scalability, the Whitepaper hinted.

India’s Manufacturing Growth & Global Competitiveness

India’s manufacturing sector is on the brink of unprecedented growth, fuelled by technology, supportive government policies, and evolving global supply chains. To remain competitive, manufacturers must prioritize technology adoption, workforce upskilling, and sustainability initiatives, while addressing geopolitical and environmental challenges, the Whitepaper suggested. By embracing Industry 4.0 and 5.0 technologies, India is well-positioned to become a global manufacturing powerhouse, achieving ambitious growth targets and redefining the future of industrial innovation.

NB: The image at top is representational; courtesy: DICV

Also Read:

Creative Synergies Transforms Challenges Into Blueprint For The Future Of Manufacturing