Material science has long been a driving force behind advancements in product design and manufacturing, influencing everything from lightweight composites to eco-friendly paint processes. Today, as the automotive industry undergoes a transformative shift toward electrification and sustainability, material innovations are playing an even more critical role in enhancing efficiency, safety, and environmental responsibility.

According to Parvinder Walia, Director of Material Science at Magna, the transition to the Car of the Future demands a renewed focus on sustainable materials and processes. The industry is not only striving for better vehicle performance but also addressing climate change, resource scarcity, and waste reduction.

Revolutionary Materials Driving Automotive Innovation

The push for electrification is reshaping automotive materials, with engineers prioritising lightweight components to extend driving range and fire-resistant materials to enhance battery safety. Cutting-edge translucent materials are also gaining traction, allowing for hidden lighting elements that create sleek, futuristic designs, he mentioned in his blog. Meanwhile, sensor-integrated materials help keep autonomous driving and driver assistance systems operational by preventing obstruction from rain, ice, and debris.

Cutting Waste, Energy Use

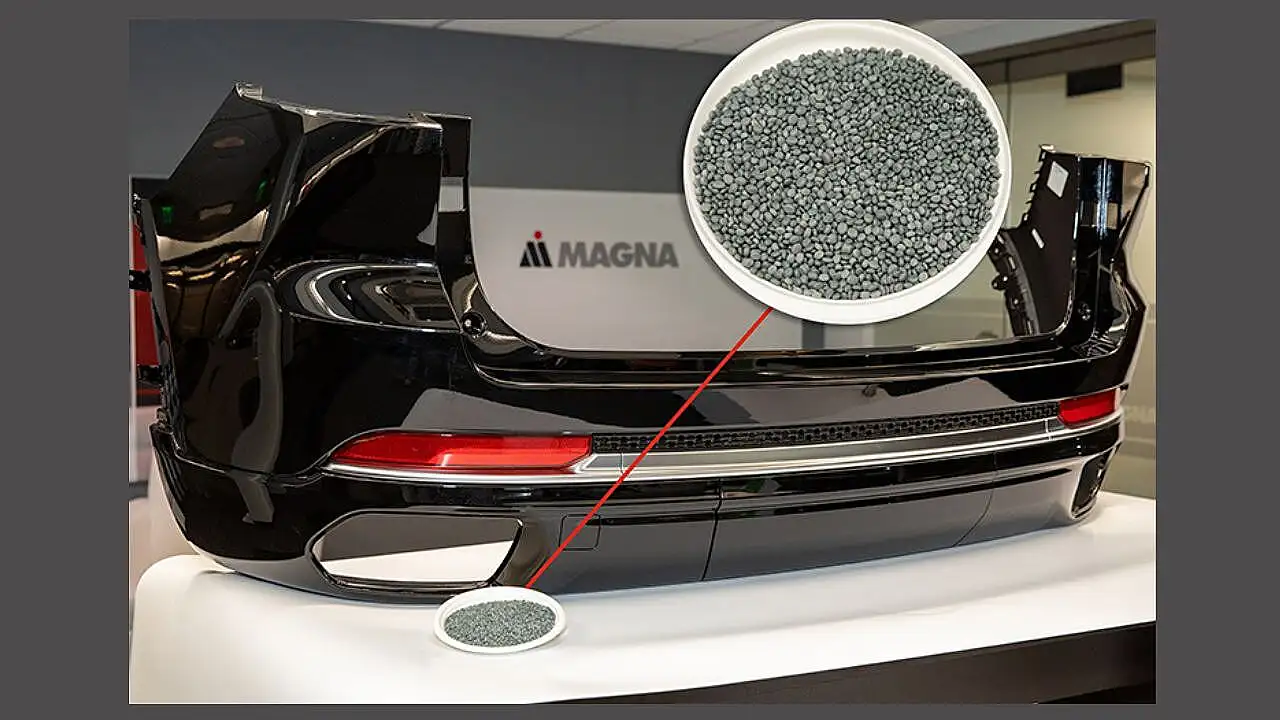

One of the biggest breakthroughs in materials innovation is happening in the paint booth—an area traditionally plagued by high waste levels and environmental challenges. Magna is leading efforts to repurpose paint sludge waste into fillers for plastics, integrating this repurposed material into plastic foam moulding at its Polycon division.

Additionally, a new in-mould painting technique is in development as a potential alternative to traditional sprayed paint. This process integrates coloured materials directly into plastic substrates, achieving near 100% efficiency, drastically reducing paint waste, and cutting energy consumption.

Balancing Performance & Environmental Responsibility

Traditional metals like steel and aluminium require vast amounts of energy for production and contribute to habitat destruction and pollution during extraction. Sustainable alternatives—such as bamboo, hemp, and recycled metals—offer lower environmental footprints while maintaining structural integrity.

One of Magna’s innovative projects involves household waste-based carbon-negative materials as an additive in plastics. Even a 5% integration of this material can cut carbon emissions by 30%. Another research initiative is exploring the potential of hemp-based automotive components, with roof racks made from hemp fibers being a strong contender for production.

A Path To Net-Zero

Magna’s innovation pipeline extends beyond materials engineering for performance and sustainability—it is also deeply invested in circular economy principles. Instead of following a linear “take, make, dispose” approach, the company is pioneering methods to extend material life cycles through recycling, remanufacturing, and repurposing.

This shift is crucial to meeting Magna’s net-zero ambitions, including its commitment to cut Scope 3 emissions by 25% by 2030. By integrating sustainable materials and adopting waste-reducing processes, Magna is minimising its carbon footprint, conserving resources, and tackling pressing global challenges such as biodiversity loss and pollution.

The Business Case For Sustainable Manufacturing

Sustainability is no longer just an ethical choice—it is a competitive advantage, he said. As consumers and businesses increasingly prioritise environmentally responsible products, manufacturers who invest in eco-friendly materials and processes will be at the forefront of the industry. Moreover, sustainability initiatives can drive long-term cost savings, with energy-efficient production methods and waste reduction strategies lowering operational expenses.

From composite structures to recyclable materials, innovative paints, and circular economy strategies, material science is shaping the future of automotive mobility. In an era where efficiency, safety, and environmental responsibility go hand in hand, pioneering new materials and manufacturing techniques has never been more essential, he added.

Also Read: